Statistical method and system for oil abrasive particles based on computer aided technology

A computer-aided, oil-abrasive technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as inability to analyze and inaccurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

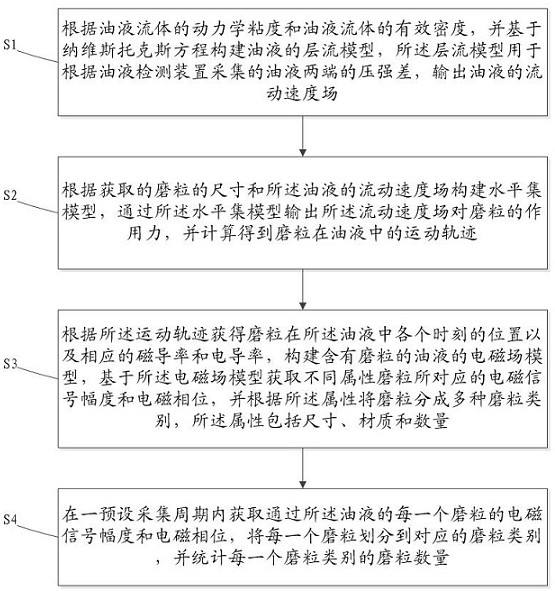

[0073] Such as figure 1 One embodiment of the present invention shown, the present invention provides a kind of method based on computer aided technology oil wear particle statistics, described method comprises:

[0074] S1. According to the dynamic viscosity of the oil fluid and the effective density of the oil fluid, and based on the Navier Stokes equation, the laminar flow model of the oil is constructed, and the laminar flow model is used for the oil collected by the oil detection device The pressure difference at both ends of the liquid, the flow velocity field of the output oil;

[0075] S2. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com