Efficient starting motor capable of being rapidly dipped in paint

A technology of starter motor and varnish dipping, which is applied in the direction of electric components, manufacturing of motor generators, shape/style/structure of winding insulation, etc., and can solve problems such as low reliability of armature coils, long varnish dipping time, and low production efficiency , to achieve the effects of low manufacturing cost, improved start-up performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

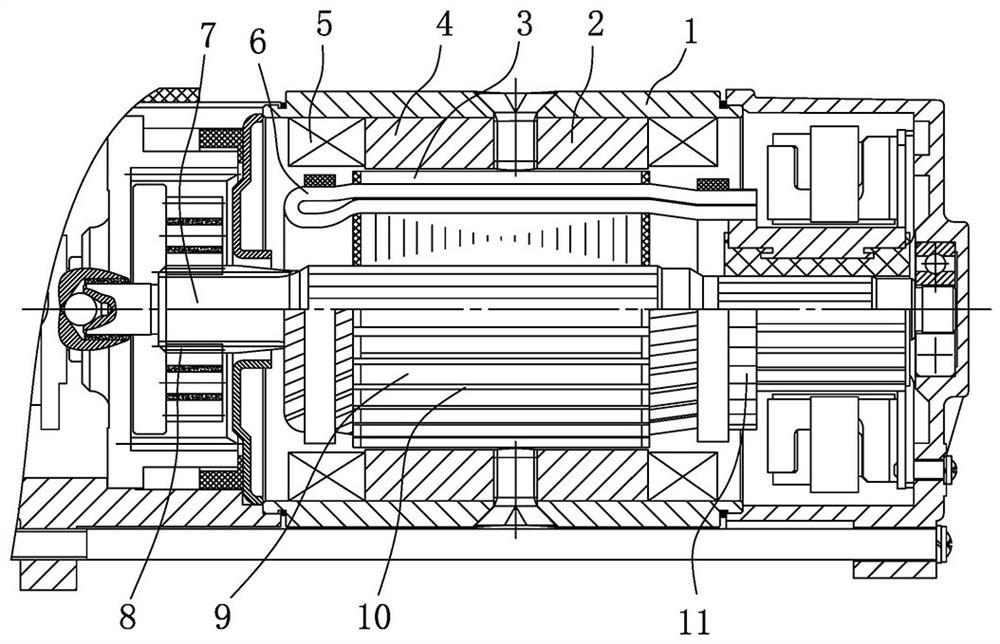

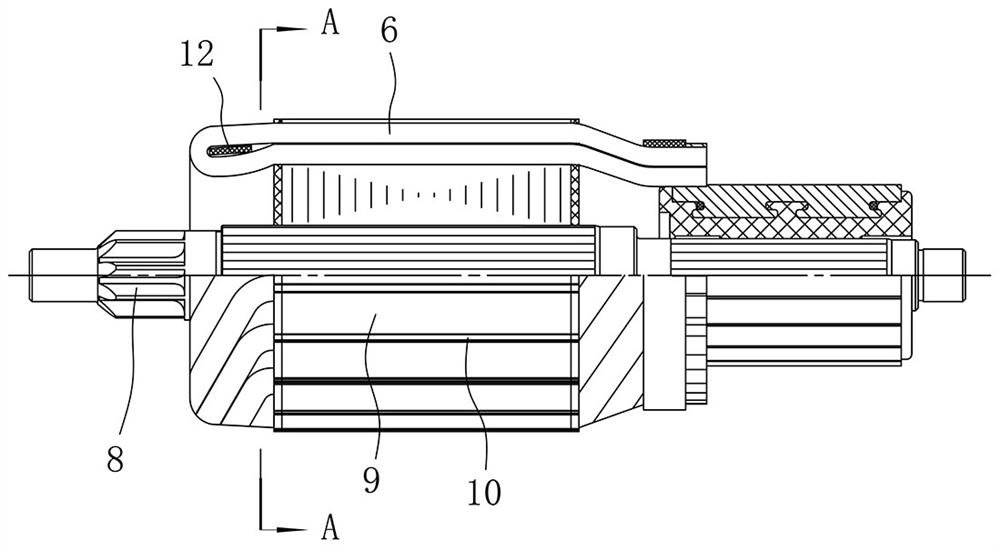

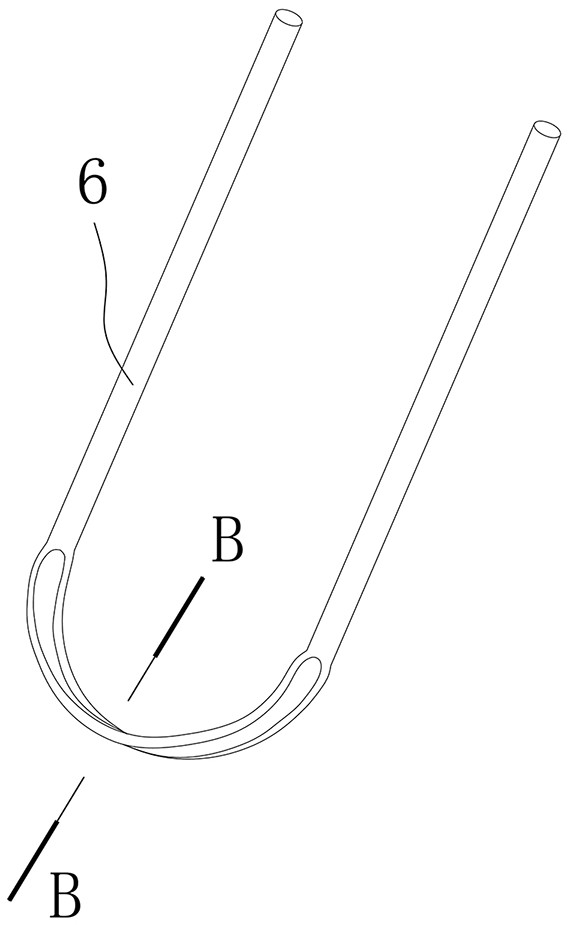

[0020] Example: A high-efficiency starter motor that can be dipped quickly, such as figure 1 As shown, it includes a casing 1, a hollow stator assembly 2 is fixedly connected to the casing 1, a rotatable rotor assembly 3 is arranged inside the stator assembly 2, and the stator assembly 2 includes an excitation The iron core 4 and the excitation coil 5 wound on the excitation core 4, the rotor assembly 3 includes an armature shaft 7, a hollow armature core 9, and an armature coil 6, and the armature core 9 is fixed Socketed on the outer peripheral side of the armature shaft 7, one end of the armature shaft 7 is provided with a driving gear 8 connected with the armature shaft 7 on the outside of the armature core 9, and the armature shaft The other end of 7 is provided with a commutator 11 outside the armature core 9, such as figure 2 , image 3 , Figure 4 As shown, the outer peripheral surface of the armature core 9 is evenly arranged with a plurality of axially extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com