Tire belt ply calendering process

A calendering process and belt layer technology, applied in the field of tire belt calendering process, can solve the problems of reduced production efficiency, semi-finished product quality, fluctuation of natural rubber quality, etc., to improve production efficiency, solve the problem of sticking rollers, and uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

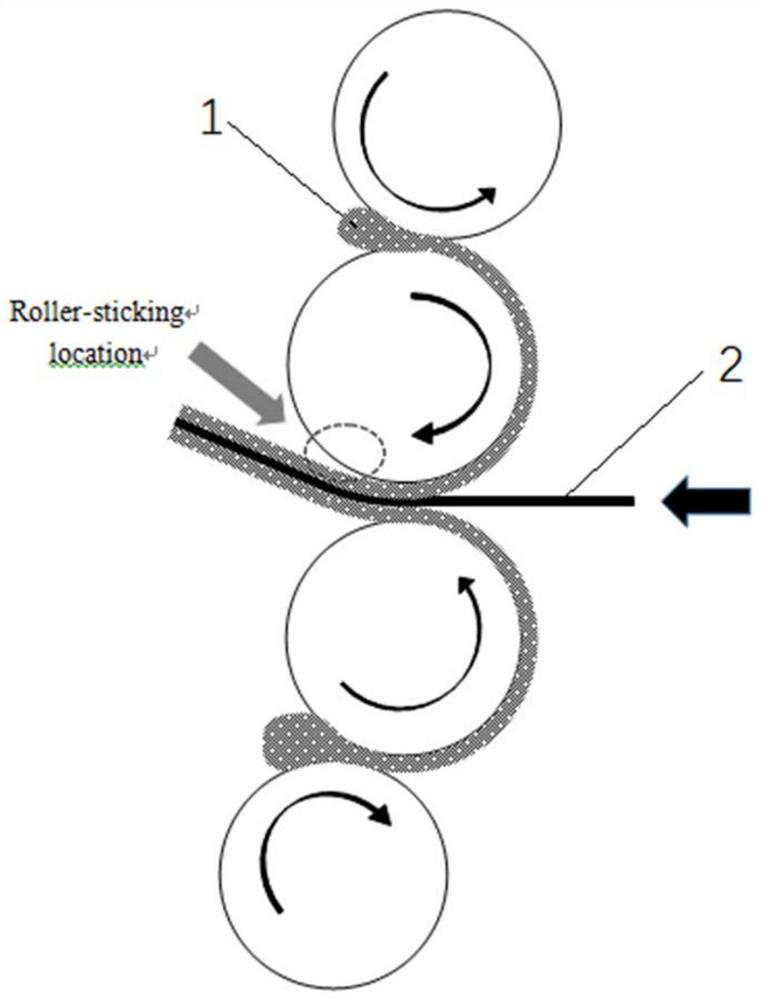

[0017] A tire belt layer calendering process, the tire belt layer calendering process includes the step of using a four-roller calender to bond the glued steel wire, the glue supply temperature is 95 ° C, the upper part of the four-roller calender The temperature of the rolls is 60°C, the temperature of the middle roll is 60°C, the temperature of the side rolls is 85°C, the temperature of the bottom rolls is 85°C, and the temperature of the belt layer is maintained at 80°C.

[0018] The speed ratio of the side roller, the upper roller, the middle roller and the lower roller is 1:1.3:1.3:1.

[0019] The height of the rubber sealing glue 1 piled up on the side rollers, upper rollers, middle rollers and lower rollers is 10cm. The surface temperature of the steel cord 2 before bonding was 60°C.

[0020] In the step of laminating the glued steel wires using a four-roll calender, an open mill and an extruder are used to simultaneously supply the rubber sealing glue 1 .

[0021] Th...

Embodiment 2

[0023] A tire belt layer calendering process, the tire belt layer calendering process includes the step of using a four-roller calender to bond the glued steel wire, the glue supply temperature is 105 ° C, the upper part of the four-roller calender The temperature of the rolls is 70°C, the temperature of the middle roll is 70°C, the temperature of the side rolls is 95°C, the temperature of the bottom rolls is 5°C, and the temperature of the belt layer is maintained at 80°C.

[0024] The speed ratio of the side roller, the upper roller, the middle roller and the lower roller is 1:1.3:1.3:1.

[0025] The height of the rubber sealing glue 1 piled up by the side rollers, upper rollers, middle rollers and lower rollers is 15cm.

[0026] The surface temperature of the steel cord 2 before bonding was 80°C.

[0027] In the step of laminating the glued steel wires using a four-roll calender, an open mill and an extruder are used to simultaneously supply the rubber sealing glue 1 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com