Pre-assembly construction and turnover hoisting method for rudder horn block of large ship

A technology of hoisting method and construction method, which can be applied to ships and other directions, and can solve problems such as the inability to solve the rotation problem of the pre-general assembly, the inability to solve the problem of temporary shelving of the pre-general assembly, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]The present invention will be further described below in conjunction with the drawings.

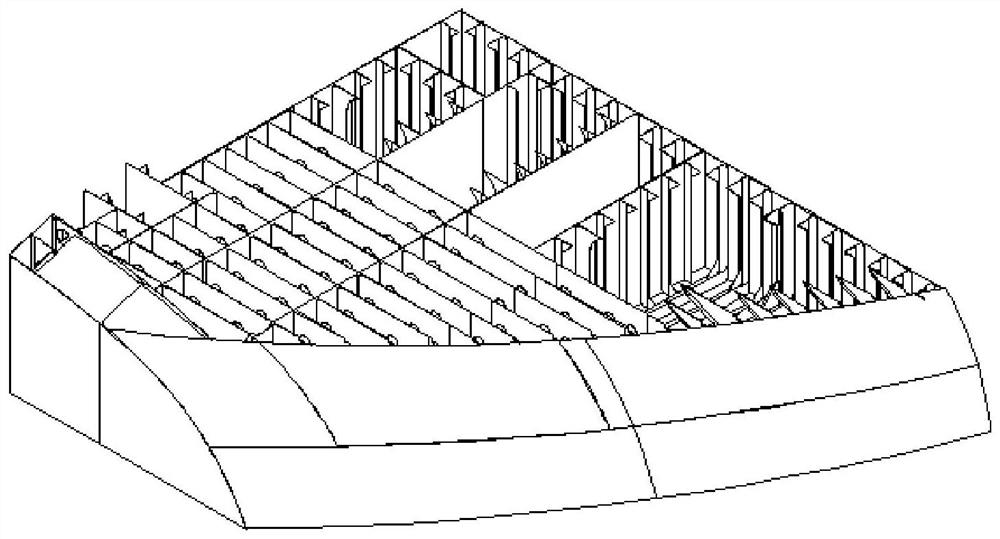

[0058]SeeFigure 1-11This embodiment provides the pre-general assembly construction and rollover lifting method of the rudder arm general section of a large ship, including the following steps:

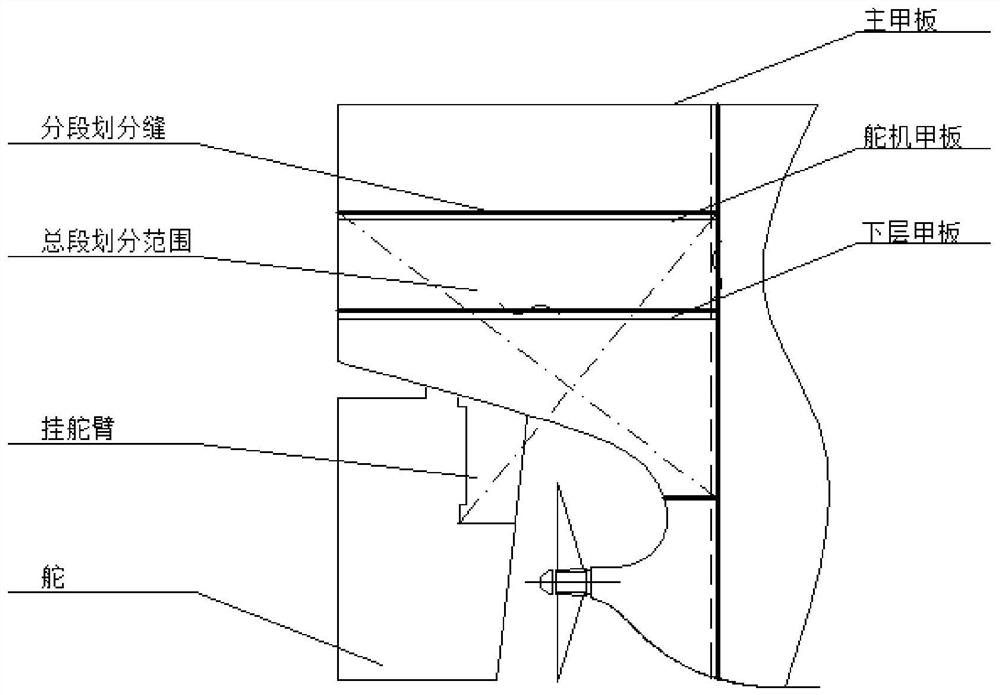

[0059]Step 1: The division method and construction method of the total section of the rudder arm:

[0060]A1. The division method of the total section of the rudder arm;

[0061]A2. The segmented construction method of the total section of the rudder arm;

[0062]A3. The construction method of the total section of the rudder arm;

[0063]Step 2: Construction method of anti-state pre-assembly;

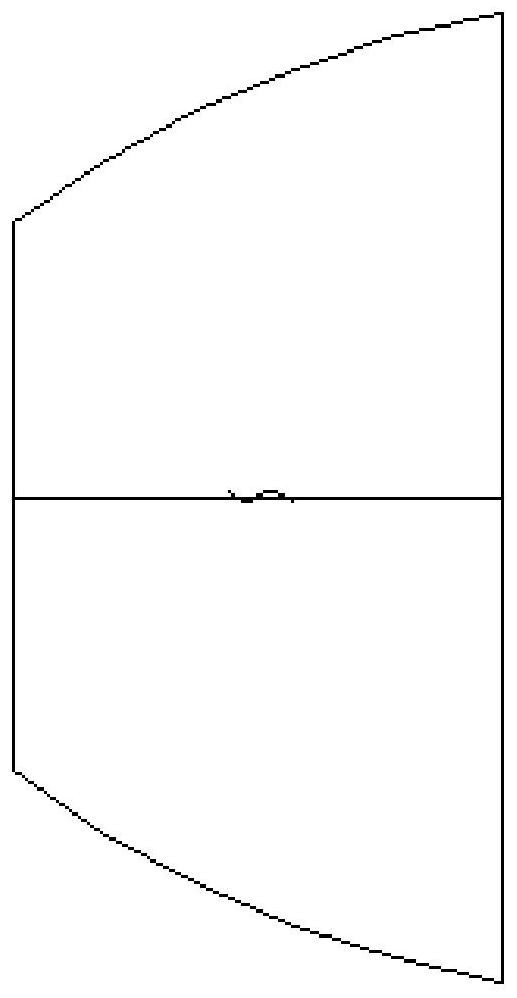

[0064]The third step: the method of turning over of the pre-general group: According to the shape and size of the pre-general group, especially when the width of the bottom and bottom of the trapezoid has a large difference, it is not advisable to roll over laterally (turn over with the length of the pre-general group as the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com