Production method of apple-pear distilled liquor

A production method and technology for distilled wine, which are applied in the production field of apple-pear distilled wine, can solve the problems of lack of apple-pear characteristic aroma, unable to reflect product characteristics, endangering human health, etc. The effect of alcohol rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

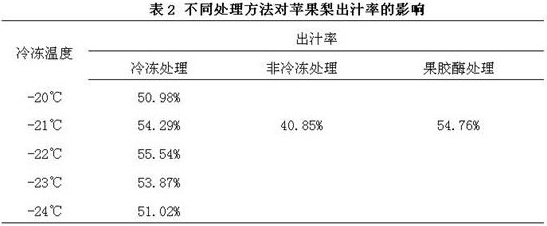

Embodiment 1

[0011] A method for preparing apple pear distilled wine, the steps are as follows:

[0012] 1) Freeze the picked raw materials under the following conditions: -21°C, 3 months;

[0013] 2) Thaw the frozen raw material in step 1) in drinking water at room temperature;

[0014] 3) Wash, crush and extract the thawed raw materials in step 2) to make apple pear distilled wine according to the conventional fruit distilled wine process.

Embodiment 2

[0016] A method for preparing apple pear distilled wine, the steps are as follows:

[0017] 1) Freeze the picked raw materials, the freezing conditions are: -22°C, 3 months;

[0018] 2) Thaw the frozen raw material in step 1) in drinking water at room temperature;

[0019] 3) Wash, crush and extract the thawed raw materials in step 2) to make apple pear distilled wine according to the conventional fruit distilled wine process.

Embodiment 3

[0021] A method for preparing apple pear distilled wine, the steps are as follows:

[0022] 1) Freeze the picked raw materials, the freezing conditions are: -23°C, 3 months;

[0023] 2) Thaw the frozen raw material in step 1) in drinking water at room temperature;

[0024] 3) Wash, crush and extract the thawed raw materials in step 2) to make apple pear distilled wine according to the conventional fruit distilled wine process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com