A high-speed rail fan assembly structure

An assembly structure and fan technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of impeller vibration, high-speed rail motor noise, etc., and achieve the possibility of reducing working noise, reducing noise, and reducing vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

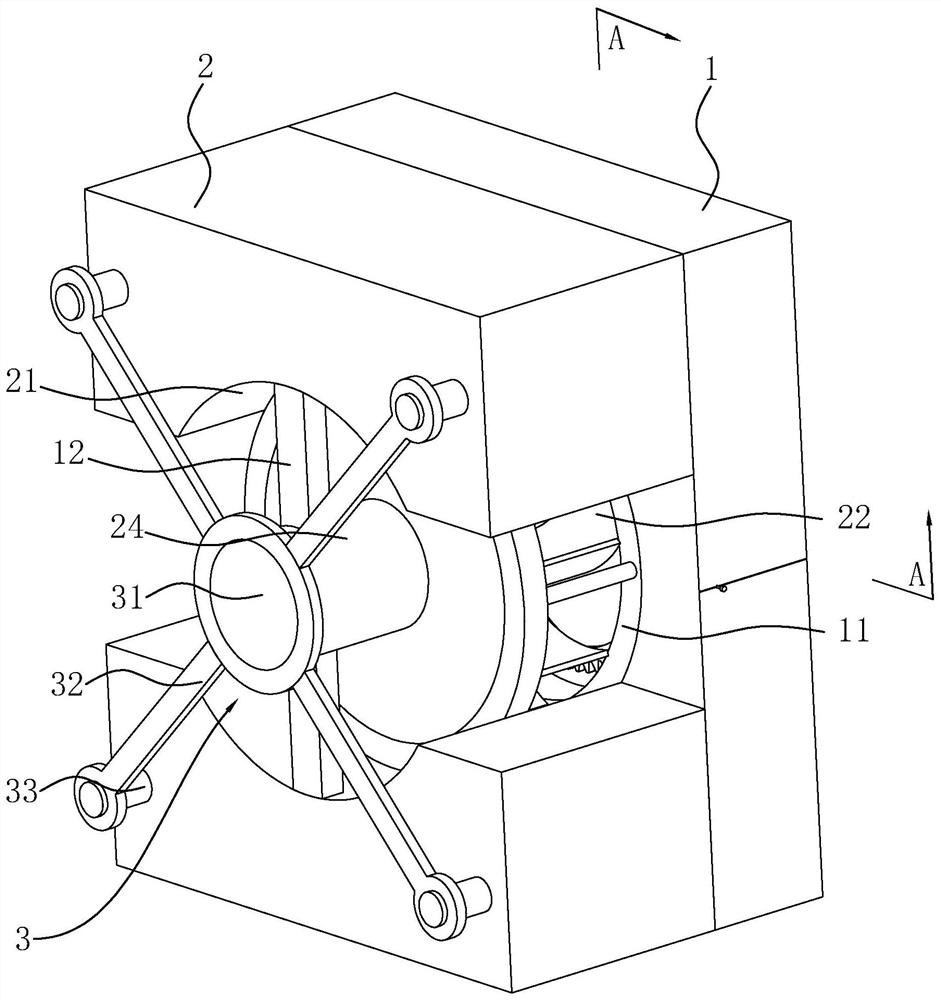

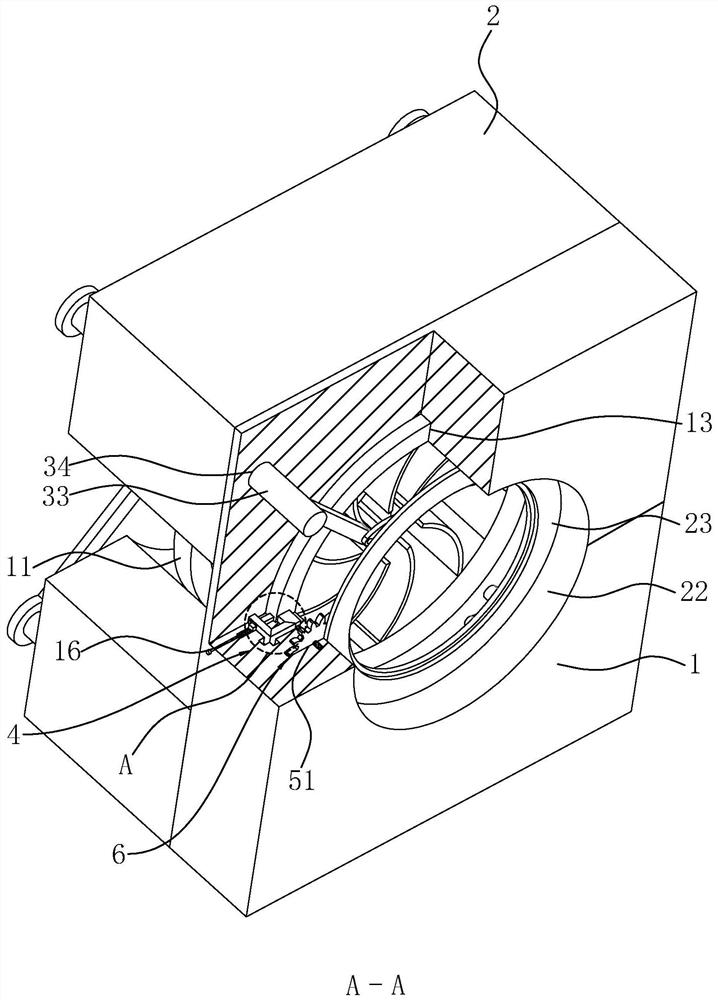

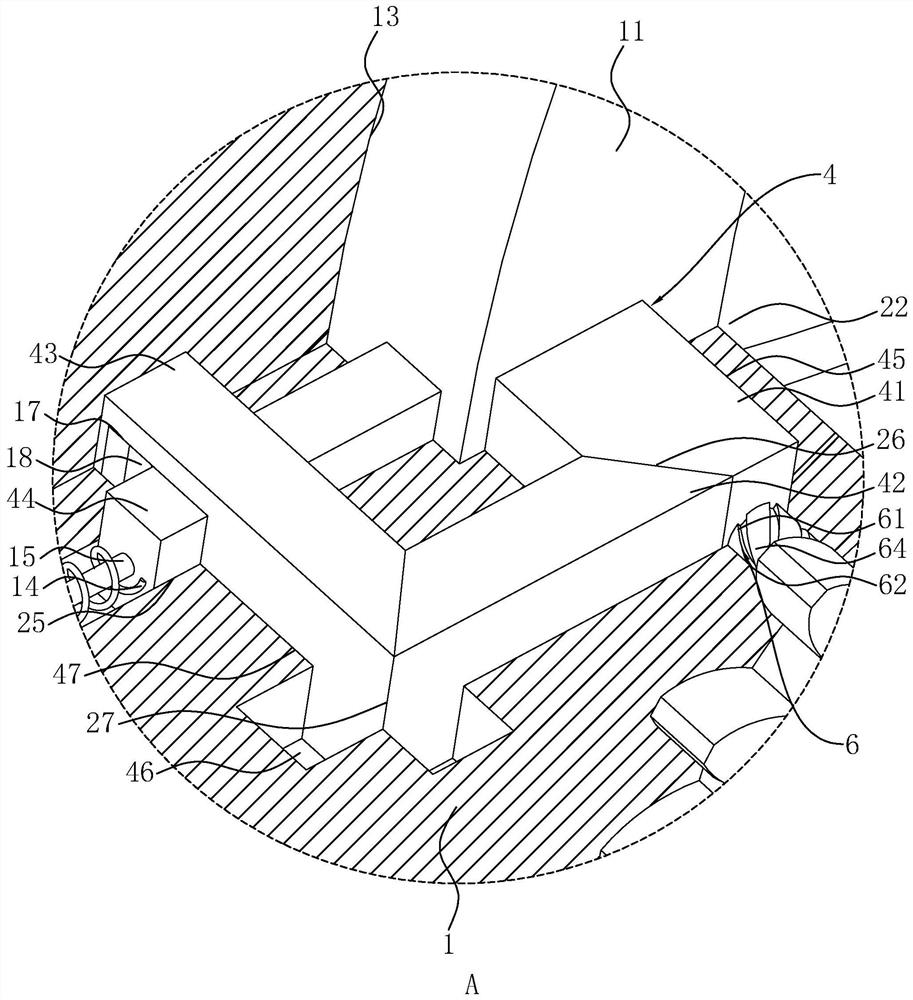

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses a high-speed rail fan assembly structure. refer to figure 1 and figure 2 , the assembly structure includes an assembly plate 1 and two support frames 2 fixed on one side of the assembly plate 1 . The assembly plate 1 is composed of two high-speed rail fan accessories, and the two high-speed rail fan accessories are fixedly connected to each other. Arc-shaped grooves 21 for accommodating fans 11 are provided on opposite inner sides of the two supporting frames 2 . By fixing the fan 11 in the two arc-shaped grooves 21, it is convenient to limit the position of the fan 11 and reduce the possibility of the fan 11 being displaced in a working state. The inner peripheral surfaces of the two arc-shaped grooves 21 are respectively fixed with support rods 12 which are oppositely arranged and are respectively used to abut against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com