Dust collection motor with high torque density

A dust-absorbing motor and high-torque technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as vibration and wind wheel noise, and achieve the effects of improving connection strength, reducing noise, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

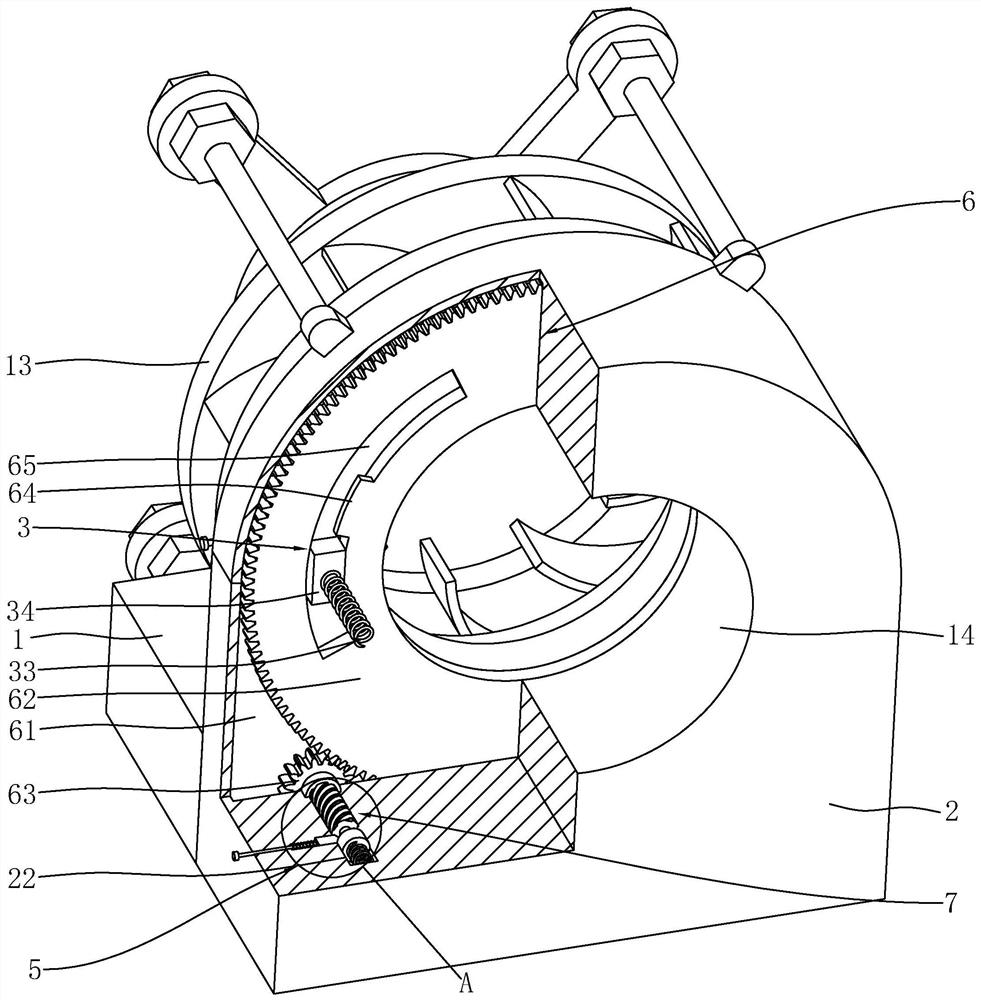

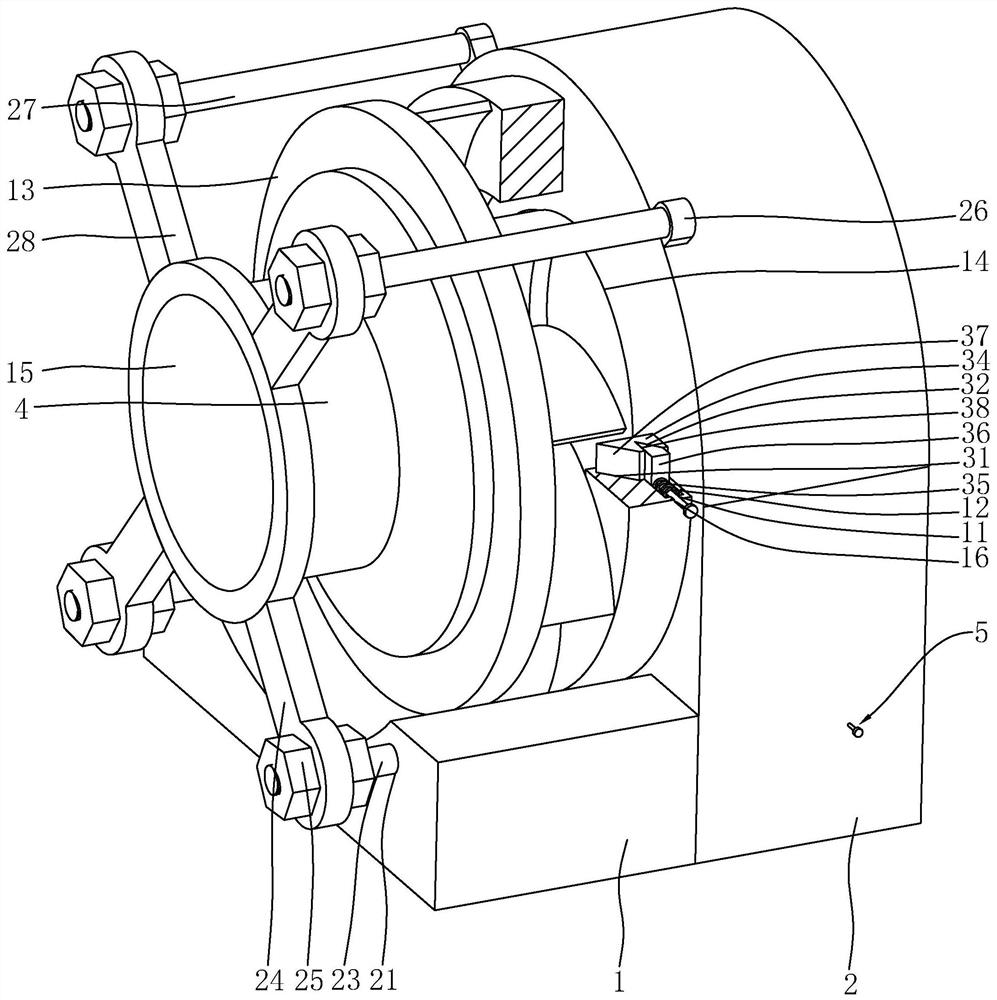

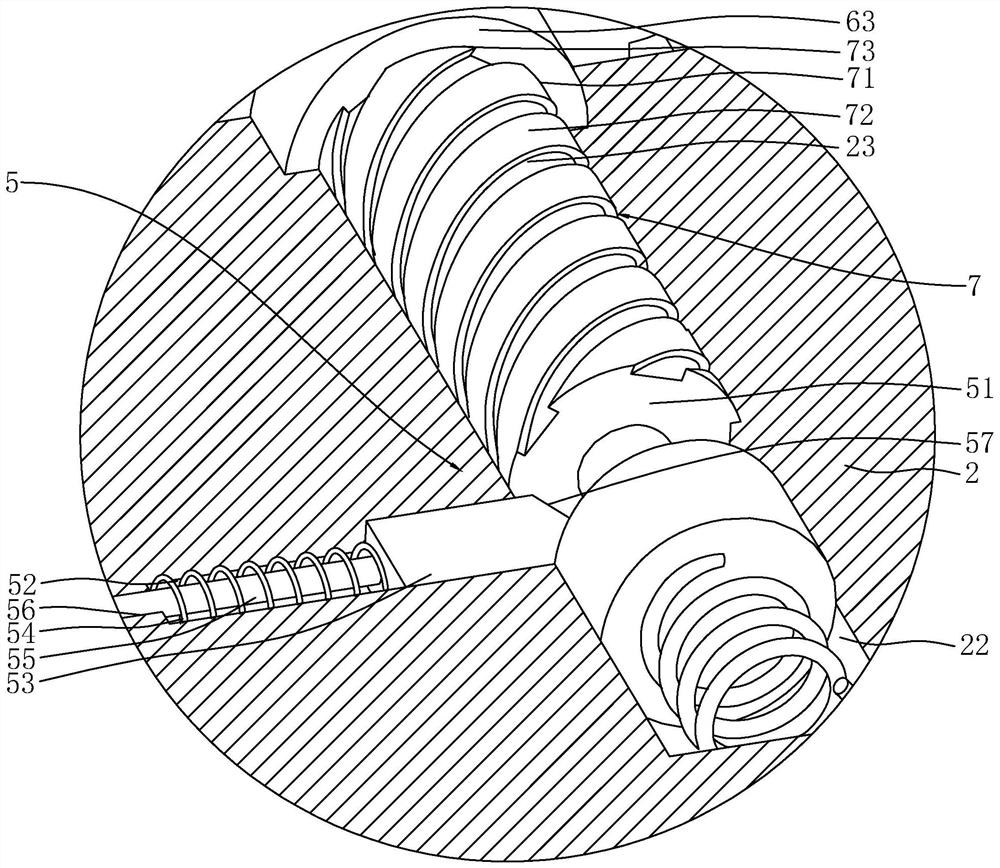

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses a dust collection motor 4 with high torque density. refer to figure 1 , figure 2The vacuum motor 4 includes a base 1 , a frame 2 fixed on one side of the base 1 , and a wind wheel 13 detachably mounted on the side of the frame 2 close to the base 1 . A circular through hole 14 is opened on the side of the frame 2 close to the base 1 . Two sets of fixing mechanisms 3 for fixedly connecting the machine base 2 and the wind wheel 13 are arranged between the wind wheel 13 and the machine base 2 . The base 1 is provided with two first circular grooves 21 on the side away from the base 2, and the side of the base 2 close to the base 1 is provided with two second circular grooves 22 respectively communicating with the first circular grooves 21; In the first circular groove 21, a first connecting shaft 23 is provided to slide al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com