Method for Eliminating Cavitation and Vibration Damage of Arc Gate Bottom Water Seal and Connecting Parts

A vibration damage and arc gate technology is applied in the field of eliminating the bottom water seal of the arc gate and the cavitation erosion and vibration damage of the connecting parts. , The effect of reducing construction difficulty and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

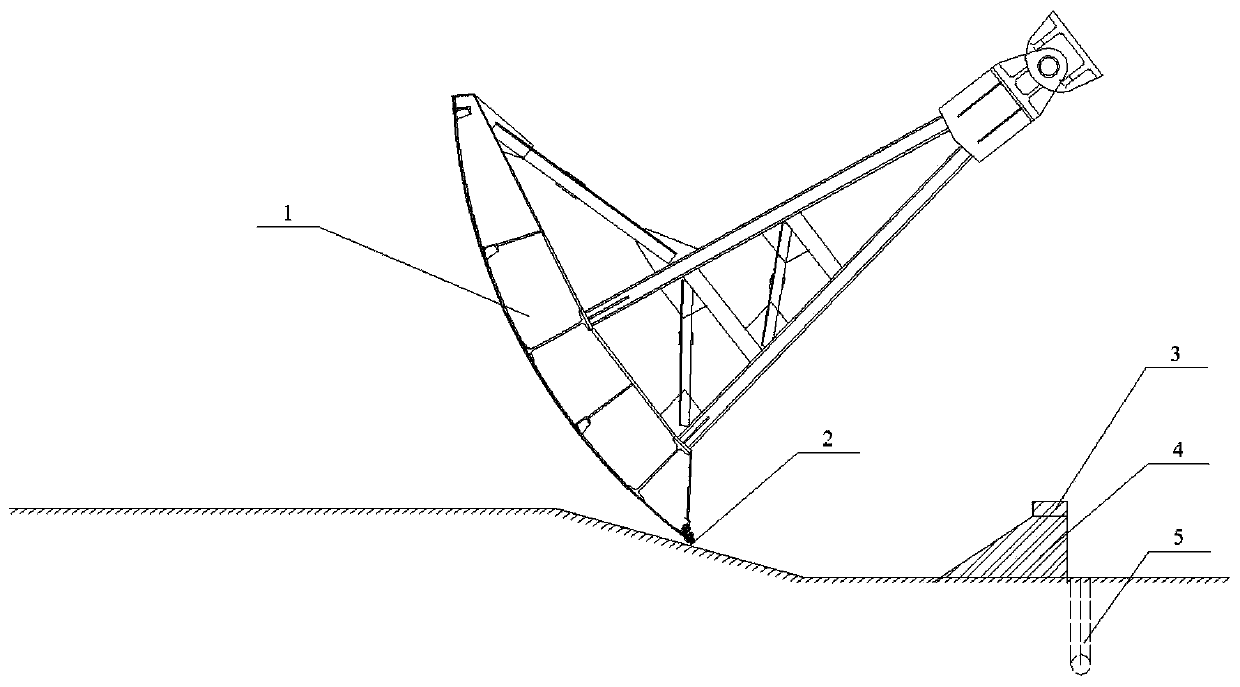

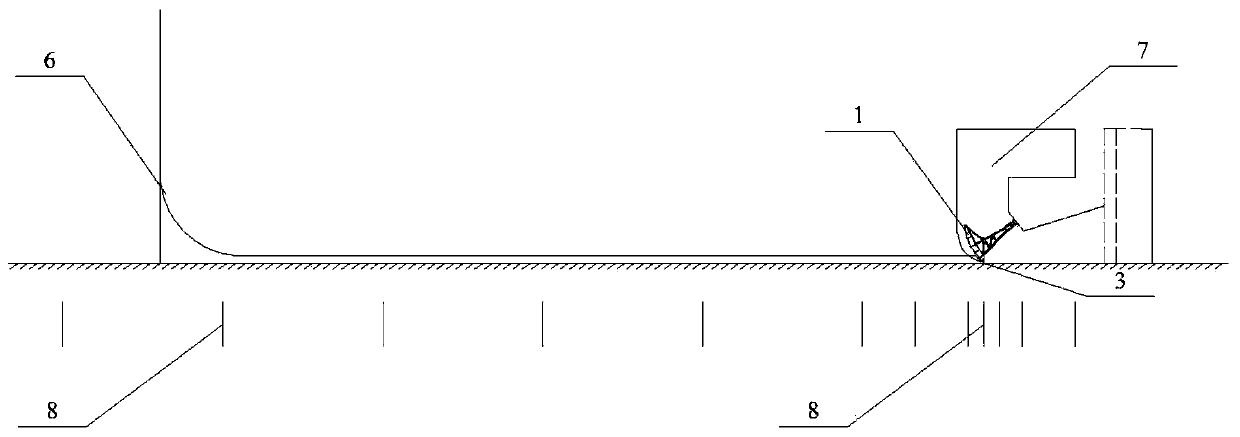

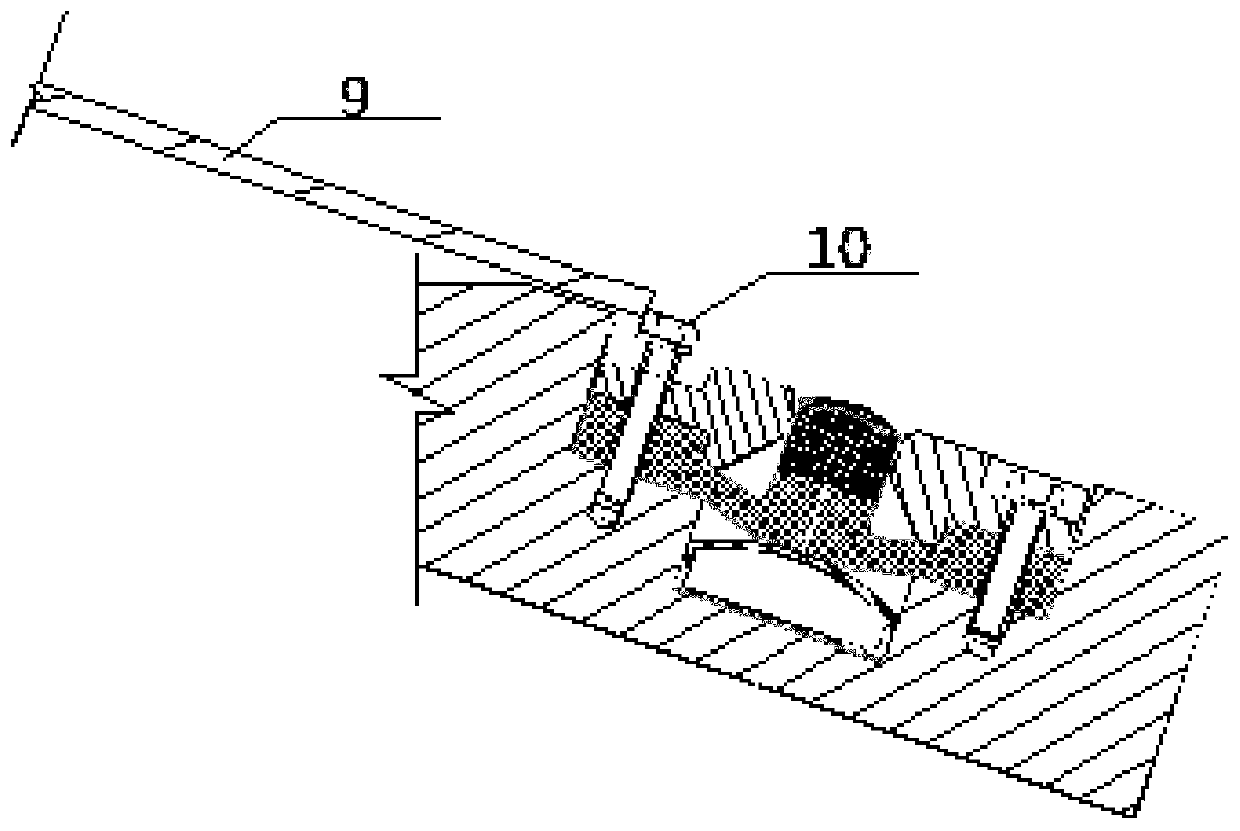

[0027] The specific implementation of the method for eliminating the cavitation and vibration damage of the bottom water seal of the arc gate and the connecting parts and the vibration damage related to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028]

[0029] There is a low-level discharge tunnel at the bottom of the power plant of a certain project dam, which is used for sand washing and flood control. According to the layout of the hub, a working gate is set at the exit. After the gate was put into operation, the bolts 10 of the bottom water seal pressure plate were unscrewed after the flood season in 2009, resulting in damage to the bottom water seal pressure plate and bottom water seal 2, and cavitation was found at the corner of the bottom water seal 2 . Through the above phenomena, it is preliminarily judged that the water flow at the bottom of the gate is complicated, there is a large negative pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com