Thin-wall bearing and cross beam electric brush current-carrying friction experiment device

A thin-wall bearing and criss-cross technology, applied in the field of experimental testing equipment, can solve the problems of lack of step procedures, waste, and complicated operation, and achieve the effect of smooth transmission of current, guarantee of continuous supply, and guarantee of reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

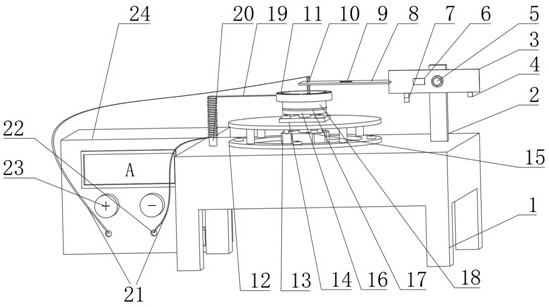

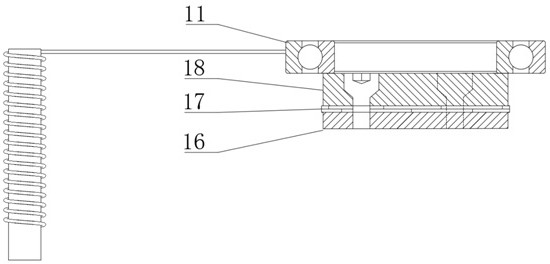

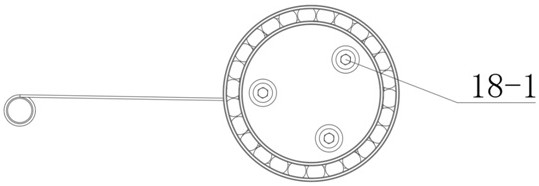

[0028] Such as figure 1 A current-carrying friction and wear experimental device for a thin-walled bearing and a cross-beam brush is mainly composed of an experimental table 1, a plastic support 2, a vertical thin plate 3, a balance magnetic block 4, a loading magnetic block 7, and a U-shaped brush Wire 10, thin-walled bearing 11, experiment platform 12, motor 13, experiment plate 18, steel wire 19, nylon column 20 etc. constitute. Fix the plastic bracket 2 on the experimental table 1, the vertical thin plate 3 is connected with the bracket 2 by the pin shaft 5, the vertical strain gauge 6 is installed on the vertical thin plate 3, the horizontal thin plate 8 is soldered to the vertical thin plate 3, and the horizontal strain gauge The sheet 9 is installed on the horizontal thin plate 8, the U-shaped electric brush wire 10 is connected with the horizontal thin plate 8 through the hole, one end of the wire 21 is connected with the U-shaped electric brush wire 10, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com