Industrial equipment control optimization method and system based on monitoring data

A technology of industrial equipment and monitoring data, applied in the field of industrial equipment control optimization based on monitoring data, can solve the problem of incomplete analysis of equipment operating status, inability to accurately grasp the working status of equipment, and failure to consider data and data correlation and synergy characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

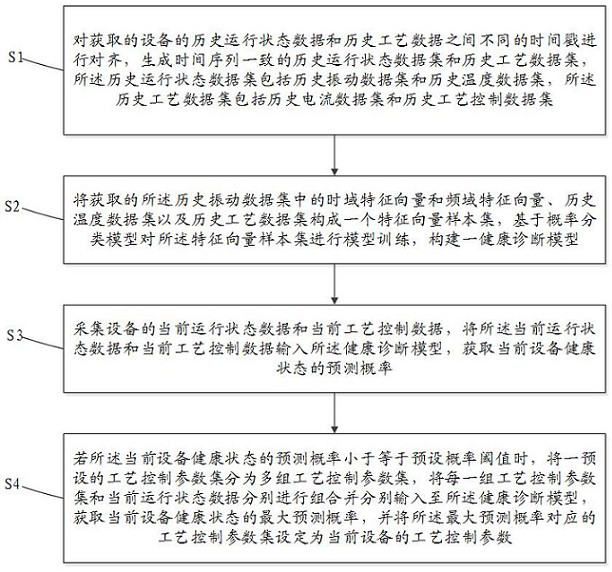

[0054] Such as figure 1 In one embodiment of the present invention shown, the present invention provides a method for optimizing control of industrial equipment based on monitoring data, the method comprising:

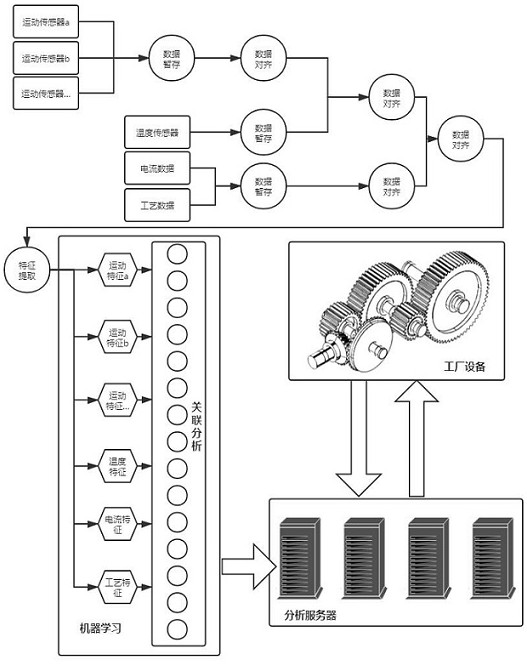

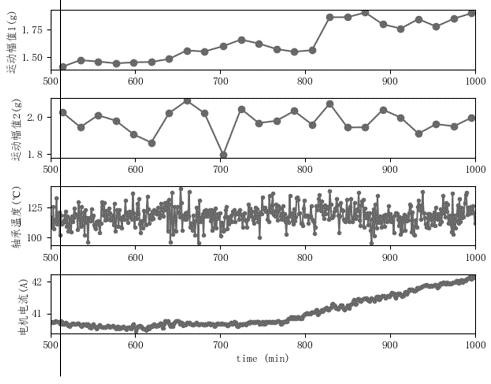

[0055] S1. Align different time stamps between the acquired historical operating state data and historical process data of the equipment, and generate a consistent time series historical operating state data set and historical process data set, the historical operating state data set includes historical vibration a data set and a historical temperature data set, the historical process data se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com