Numerical prediction method for stress relaxation and damage effects of rubber material

A rubber material and stress relaxation technology, which is applied in the field of numerical prediction of stress relaxation and damage effects of rubber materials, can solve problems affecting the normal use of the overall system of rubber products, engineering and economic losses, and service state damage, and achieve good prediction and simulation Method, easy to operate, easy to understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

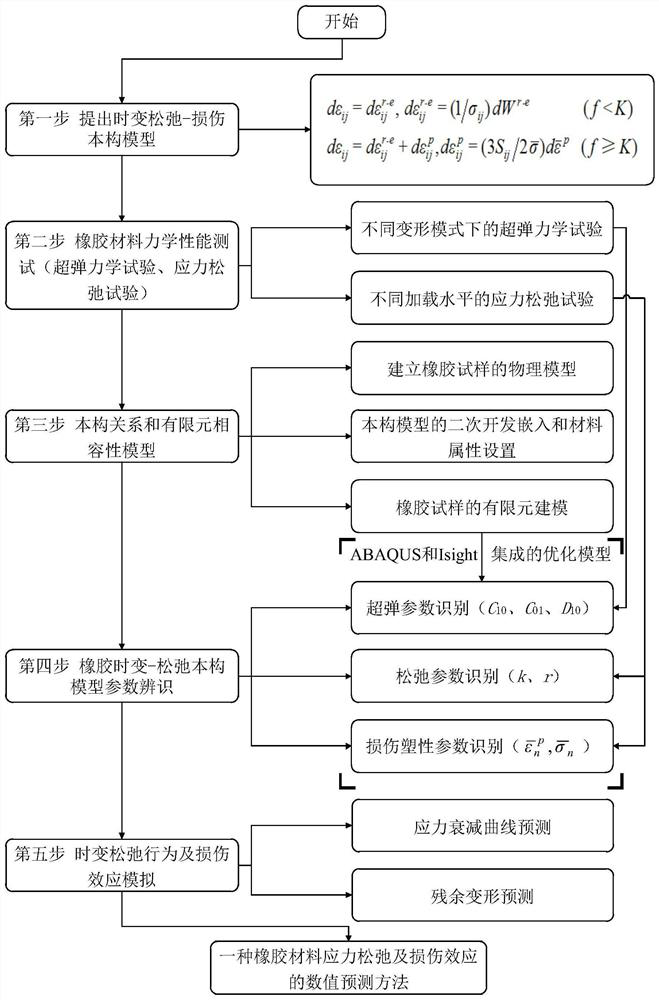

[0049] The invention provides a numerical prediction method for stress relaxation and damage effects of rubber materials, such as figure 1 As shown, the specific examples are as follows:

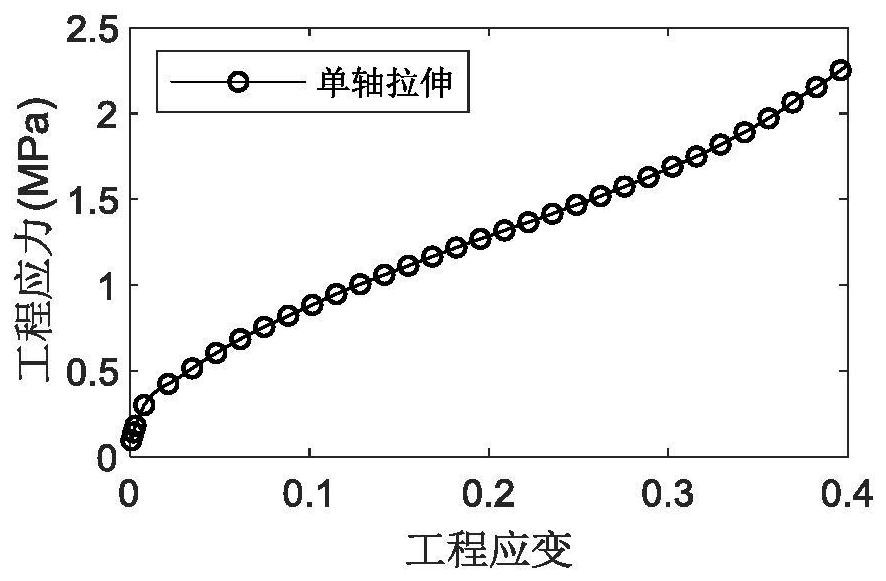

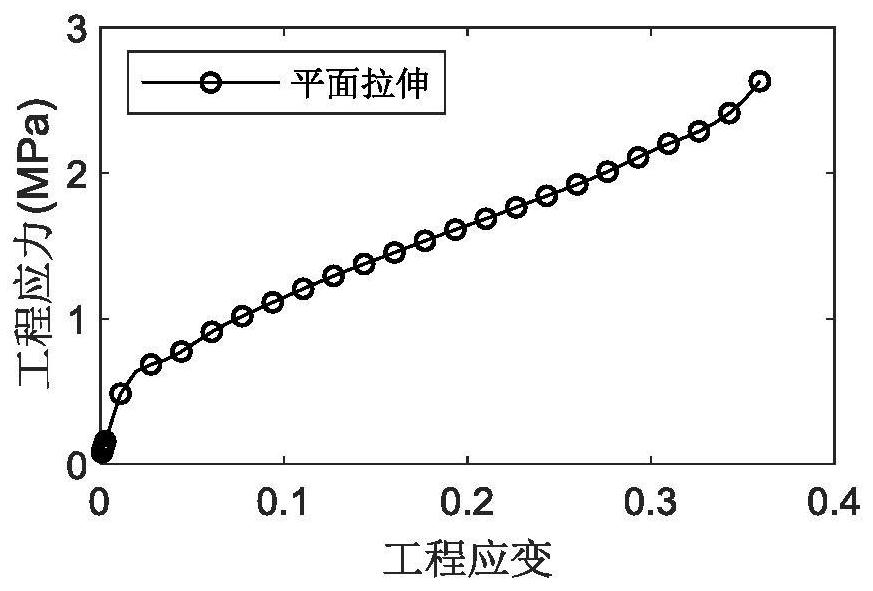

[0050] In order to verify the reliability of the constitutive model and numerical simulation method constructed in the present invention, this embodiment performs numerical prediction of the relaxation characteristics of two different types of rubber materials (nitrile rubber and hydrogenated nitrile rubber). The specific implementation steps are as follows:

[0051] Step 1: Propose time-varying relaxation-damage constitutive model

[0052] In engineering applications, rubber is often in a state of large deformation, and its mechanical characteristics can be simulated by a hyperelastic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com