Raw material screening device for powder coating production

A technology of powder coating and screening device, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of user's respiratory system injury and dust generation, and achieve the effect of preventing dust from flying, the device is fixed and stable, and it is convenient to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

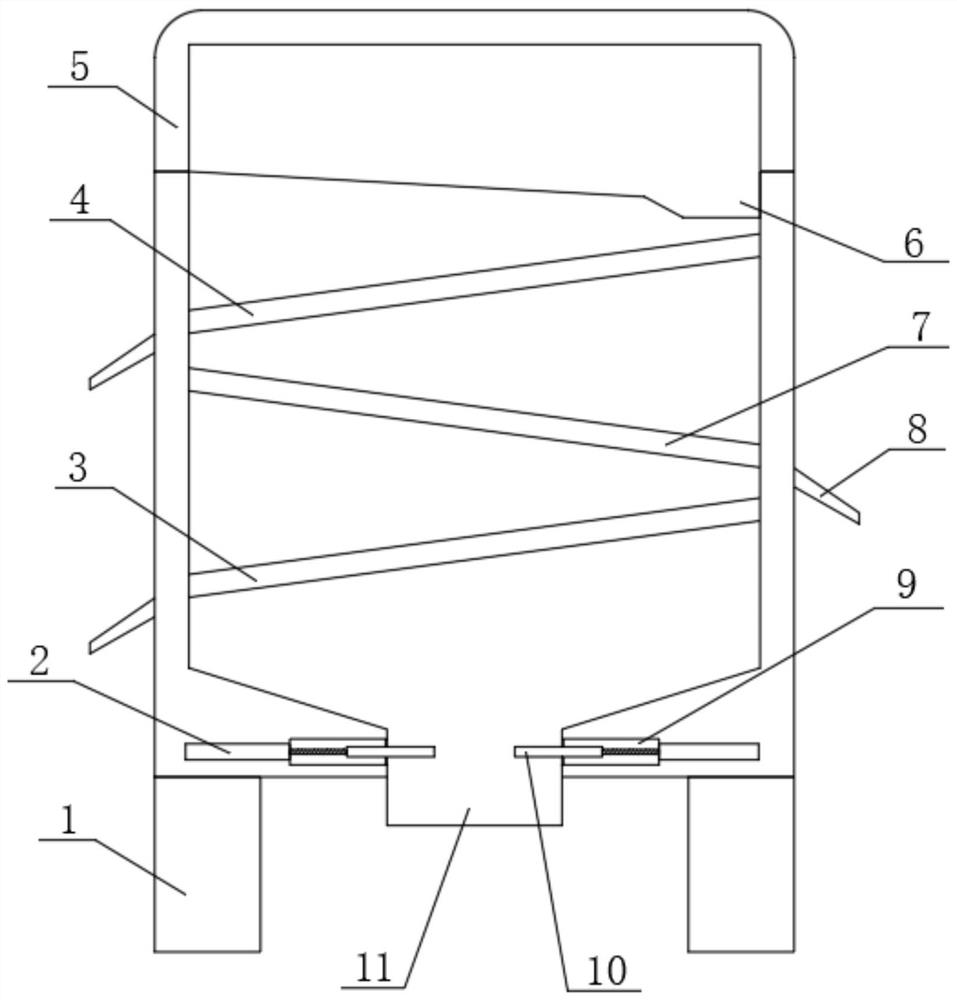

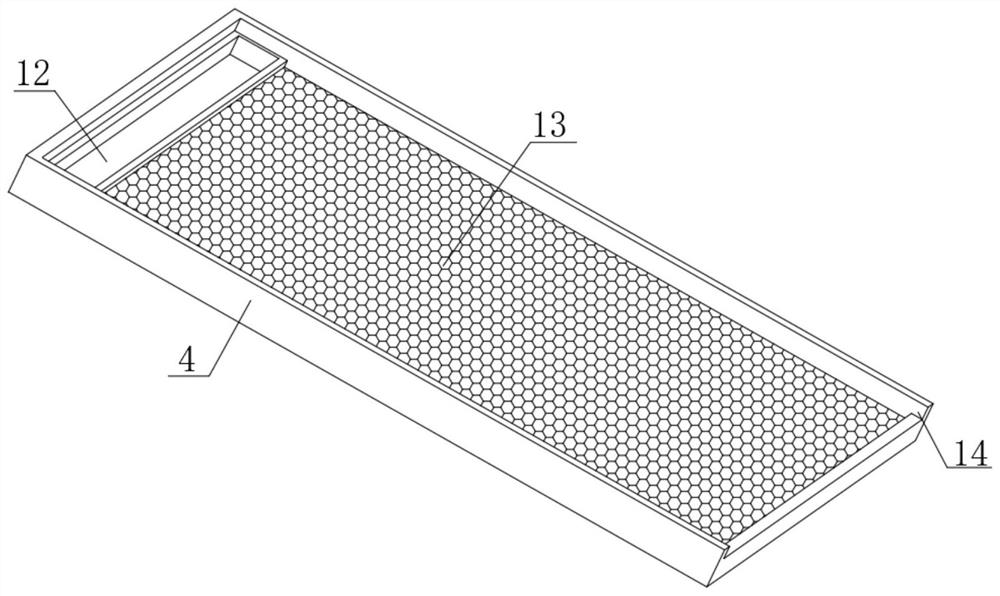

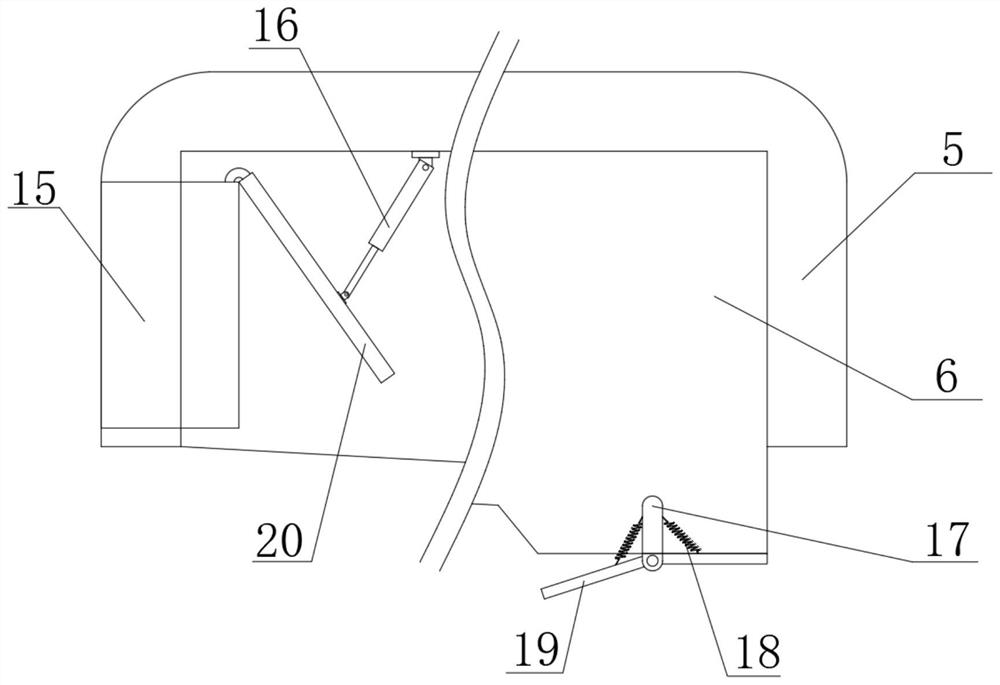

[0029] A raw material screening device for powder coating production, such as Figure 1-3 Shown, comprise main frame 5, the middle position of the inner wall of both sides of main frame 5 offers the screening chamber that vertically arranges, and the top inner wall of main frame 5 is fixed with the dust feeding box 6 that horizontal setting is arranged by bolt, and main frame 5 The top position between the inner walls of both ends of the main frame is connected with an inclined vibrating screen frame one 4 by bolts, and the middle position between the inner walls of the two ends of the main chassis 5 is fixed with an oblique vibrating screen frame two 7. The bottom between the end inner walls is connected with an inclined vibrating screen frame 3 3 by bolts, and a first hole is provided at one end of the dust feeding box 6, and the first hole is sleeved with a horizontally arranged feeding bin 15, and the feeding bin 15 One end of the top position of the dust feeding box 6 is ...

Embodiment 2

[0033] A raw material screening device for powder coating production, such as Figure 1-4 As shown, the middle of the bottom of the support column 1 is provided with a vertically arranged moving groove 23, and the top inner wall of the moving groove 23 is socketed and fixed with a vertically arranged hydraulic cylinder 22, and the middle position of the bottom of the hydraulic cylinder 22 is fixed with a vertical The moving wheel 21 that is arranged vertically, and the moving wheel 21 is socketed with the inside of the moving groove 23 .

[0034] When this embodiment is in use, in embodiment two, on the basis of embodiment one, a moving groove 23 is provided at the bottom of the support column 1, and a hydraulic cylinder 22 is sleeved on the top inner wall of the moving groove 23, and the hydraulic cylinder The bottom of 22 is equipped with mobile wheels 21. When the device is moved, the mobile wheels 21 can be directly stretched out to facilitate the movement of the device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com