Vertical drilling machine device for machining

A vertical drilling machine and mechanical processing technology, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as low efficiency, and achieve the effect of improving work efficiency and dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

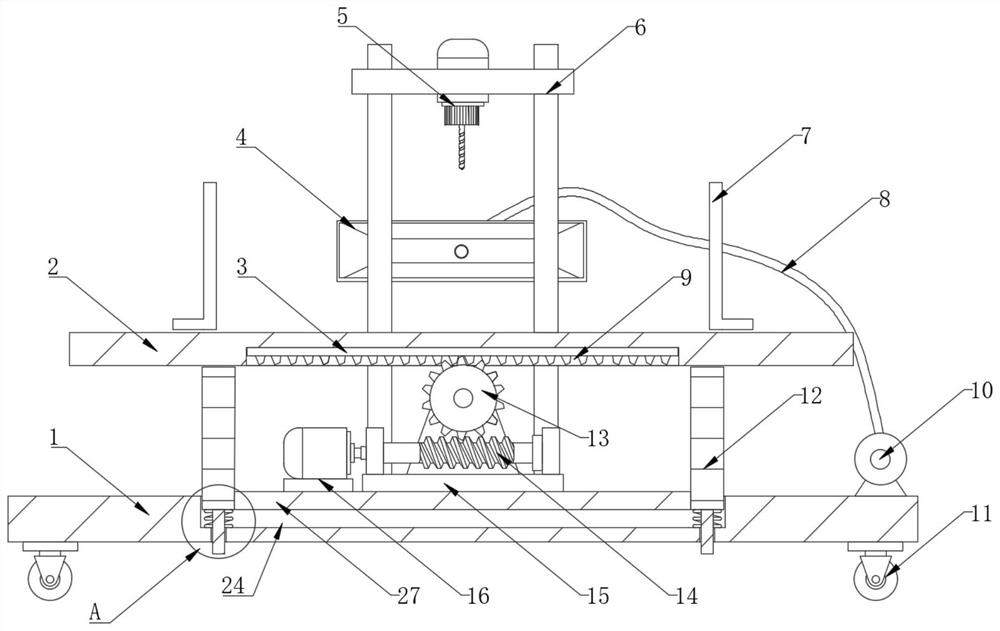

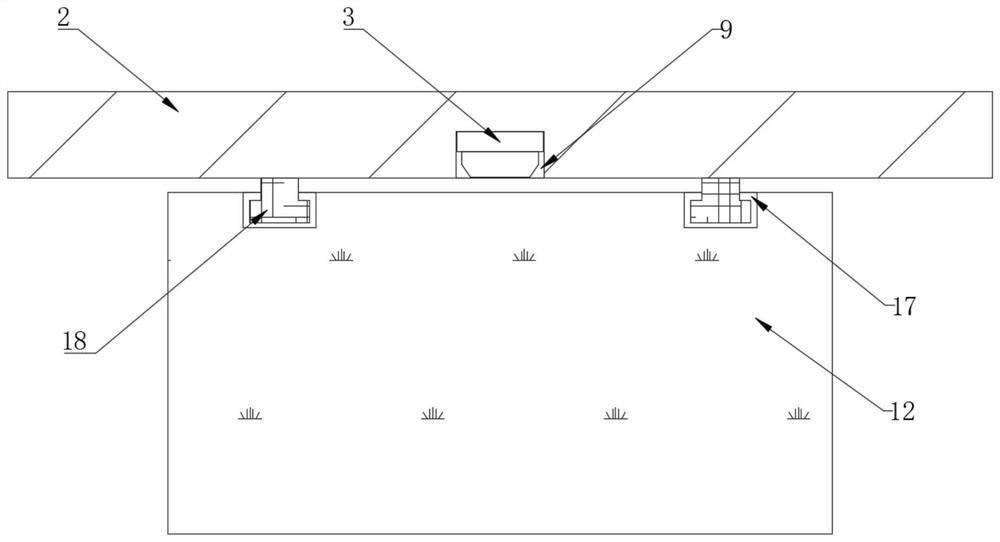

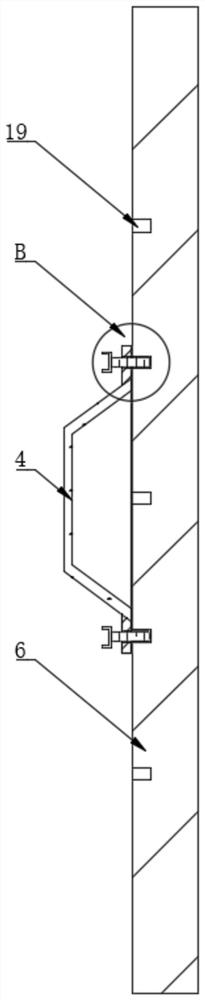

[0027] see Figure 1~5 , in an embodiment of the present invention, a vertical drilling machine equipment for mechanical processing, including a base 1, the four corners of the bottom of the base 1 are connected with moving wheels 11, and the top of the base 1 is connected with two support plates 12, the base 1 The rear part of the top is provided with a frame 6, the top of the frame 6 is equipped with a drilling rig 5, and the tops of the two support plates 12 are jointly connected with a workbench 2, and the top of the workbench 2 is provided with two clamps 7, two support plates 12 is provided with connecting horizontal plate 27, and the top of connecting horizontal plate 27 is equipped with motor 16, and the top of connecting horizontal plate 27 is provided with mounting seat 15, and the top of mounting seat 15 outside is provided with gear 13, and the inboard of mounting seat 15 is installed There is a worm screw 14, the middle position of the bottom end of the workbench ...

Embodiment 2

[0035] refer to figure 1 and 6, a vertical drilling machine used for mechanical processing. Compared with Embodiment 1, this embodiment also includes a second installation groove 24 on the top of the base 1, and several limit positions at equal distances on both sides of the bottom of the base 1. The through hole 25 and the inner sides of the second mounting groove 24 are equidistantly equipped with several damping springs 23 , and the bottom end of the support plate 12 is equidistantly connected with several limit rods 26 .

[0036] Wherein, one end of the shock absorbing spring 23 is connected with the top of the base 1, the other end of the shock absorbing spring 23 is connected with the bottom of the support plate 12, and the limit rod 26 is arranged between the shock absorber spring 23 and the limit through hole 25. internal.

[0037] Working principle: When the drilling machine 5 drills the workpiece, the workpiece will vibrate to a certain extent on the workbench 2. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com