Manufacturing process of titanium cup with arc-shaped bottom

A manufacturing process, arc-shaped bottom technology, applied in the field of arc-shaped bottom titanium cup manufacturing process, can solve problems such as easy oxidation, large arc vacuum bottom is easy to lose circle, welding is easy to shift and misplace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

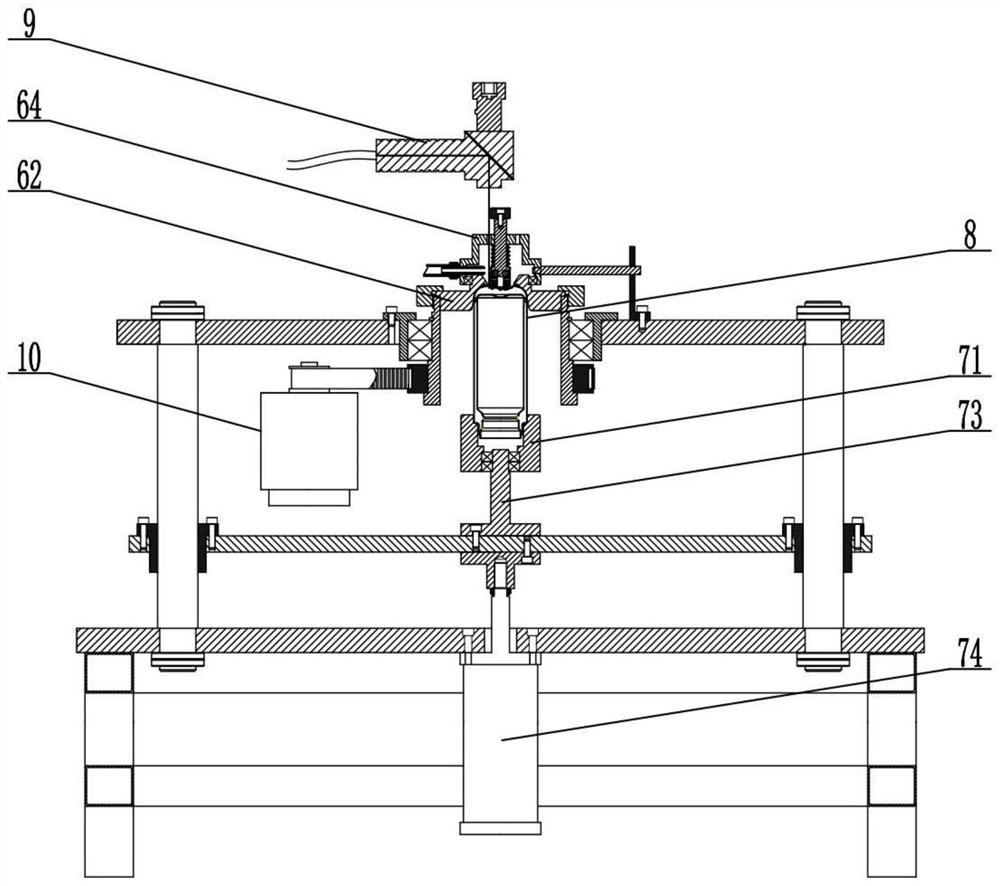

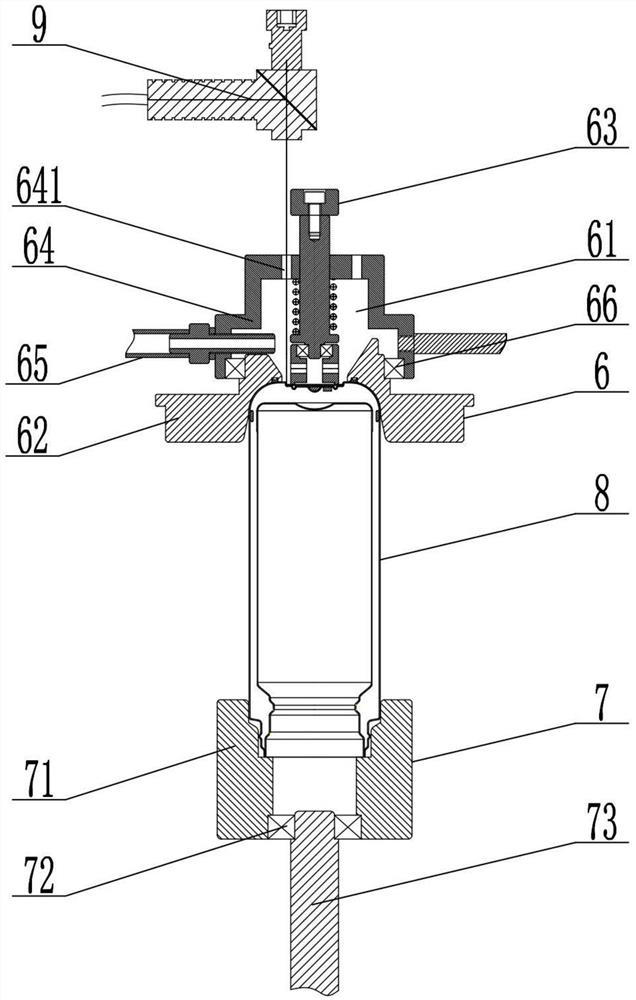

[0066] A manufacturing process of an arc-shaped bottom titanium cup, comprising the following preparation steps:

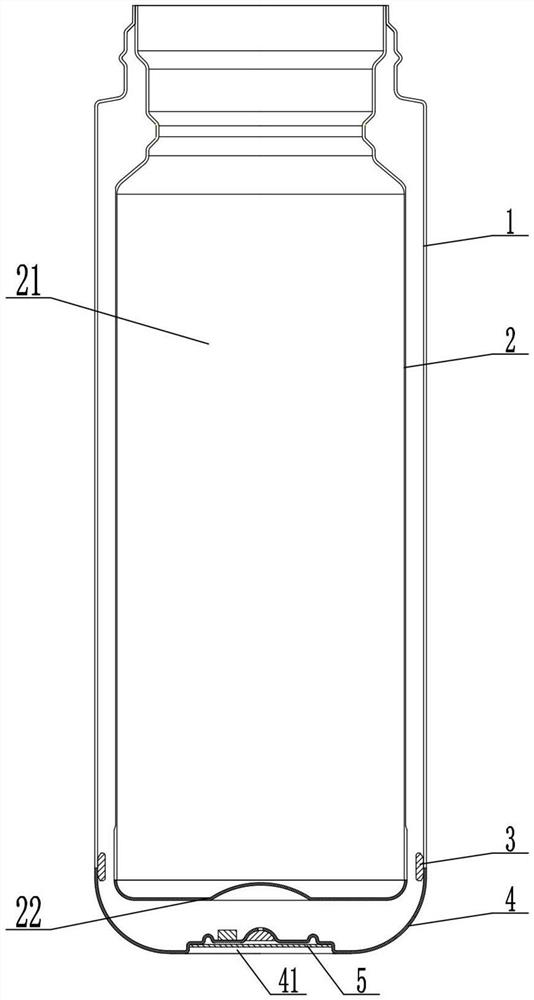

[0067] S1: Press the inner support ring 3: take the inner support ring 3 and the pretreated titanium cup shell 1, press the inner support ring 3 gradually from the bottom end of the titanium cup shell 1, the inner support ring 3 Form an interference fit with the titanium cup shell 1, and set a part of the inner support ring 3 remaining outside the bottom end of the titanium cup shell 1;

[0068] S2: Primary crystallization: Use vacuum furnace A to conduct primary crystallization on the titanium cup shell 1 and the inner support ring 3, adjust the vacuum degree in vacuum furnace A to less than 0.001Pa, set the temperature at 1100°C and continue heating for 3h , so that the titanium cup shell 1 and the inner support ring 3 stick together;

[0069] S3: Matching: Take the pretreated titanium cup liner 2 and the titanium cup shell 1 after step S2 for matching, so that...

Embodiment 2

[0097] A manufacturing process of an arc-shaped bottom titanium cup, comprising the following preparation steps:

[0098] S1: Press the inner support ring 3: take the inner support ring 3 and the pretreated titanium cup shell 1, press the inner support ring 3 gradually from the bottom end of the titanium cup shell 1, the inner support ring 3 Form an interference fit with the titanium cup shell 1, and set a part of the inner support ring 3 remaining outside the bottom end of the titanium cup shell 1;

[0099] S2: Primary crystallization: Use vacuum furnace A to conduct primary crystallization on the titanium cup shell 1 and the inner support ring 3, adjust the vacuum degree in vacuum furnace A to less than 0.001Pa, set the temperature at 1200°C and continue heating for 10h , so that the titanium cup shell 1 and the inner support ring 3 stick together;

[0100] S3: Matching: Take the pretreated titanium cup liner 2 and the titanium cup shell 1 after step S2 for matching, so tha...

Embodiment 3

[0128] A manufacturing process of an arc-shaped bottom titanium cup, comprising the following preparation steps:

[0129] S1: Press the inner support ring 3: take the inner support ring 3 and the pretreated titanium cup shell 1, press the inner support ring 3 gradually from the bottom end of the titanium cup shell 1, the inner support ring 3 Form an interference fit with the titanium cup shell 1, and set a part of the inner support ring 3 remaining outside the bottom end of the titanium cup shell 1;

[0130]S2: Primary crystallization: Use vacuum furnace A to conduct primary crystallization on the titanium cup shell 1 and the inner support ring 3, adjust the vacuum degree in vacuum furnace A to less than 0.001Pa, set the temperature at 1150°C and continue heating for 7h , so that the titanium cup shell 1 and the inner support ring 3 stick together;

[0131] S3: Matching: Take the pretreated titanium cup liner 2 and the titanium cup shell 1 after step S2 for matching, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com