Commercial concrete anti-solidification mechanical stirring device

A technology for commercial concrete and mechanical mixing, applied in cement mixing devices, clay preparation devices, liquid batching supply devices, etc., can solve the problems of long distance between mixing sites and construction sites, reduce convenience, etc., to prevent solidification and ensure uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

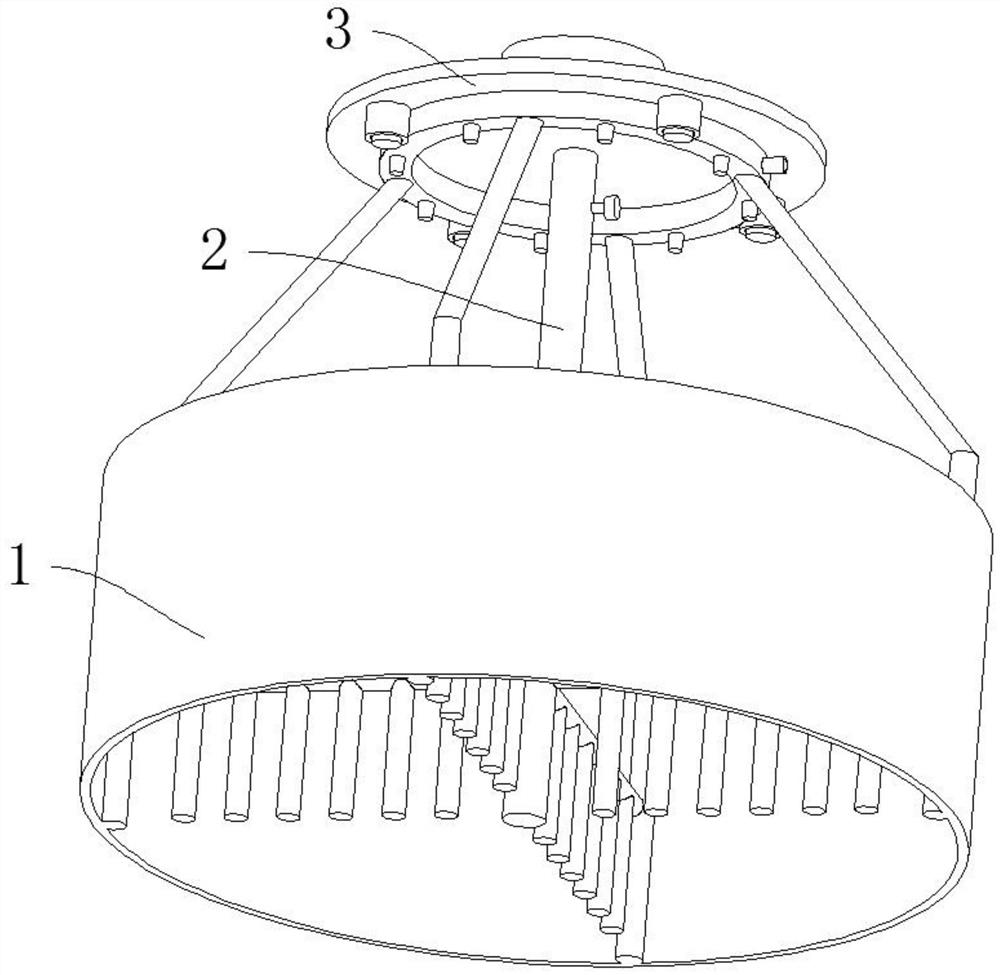

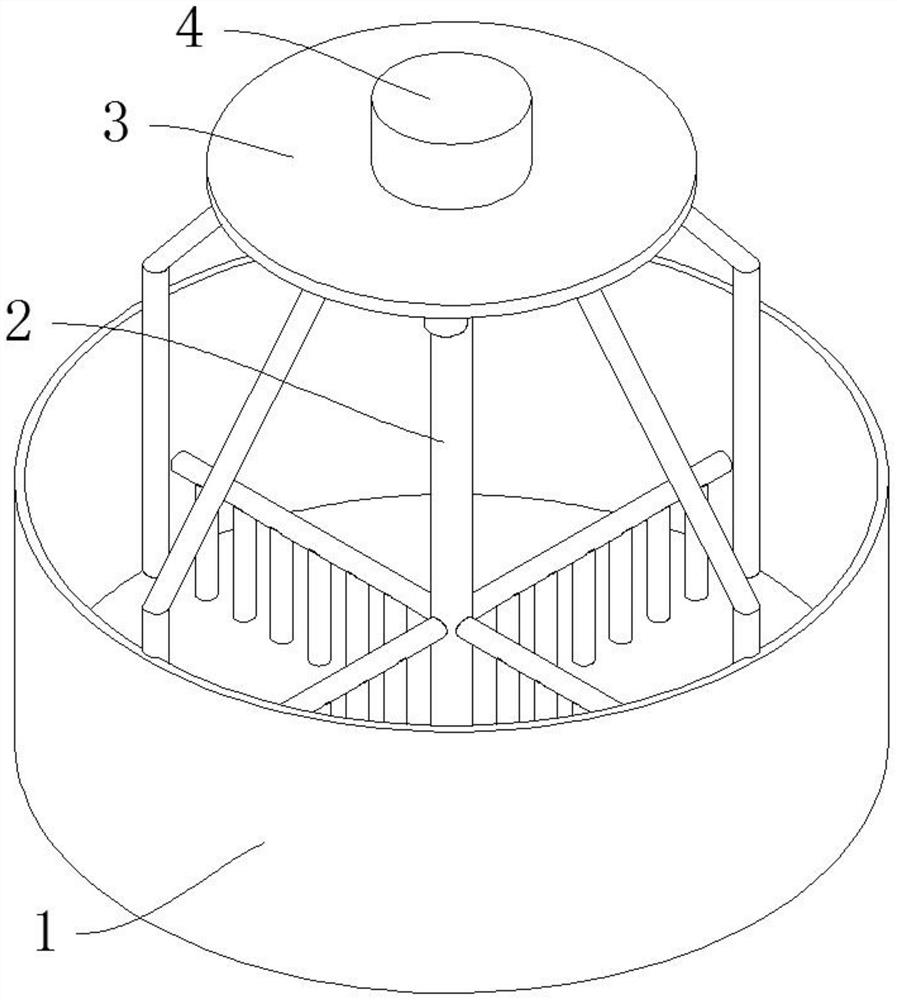

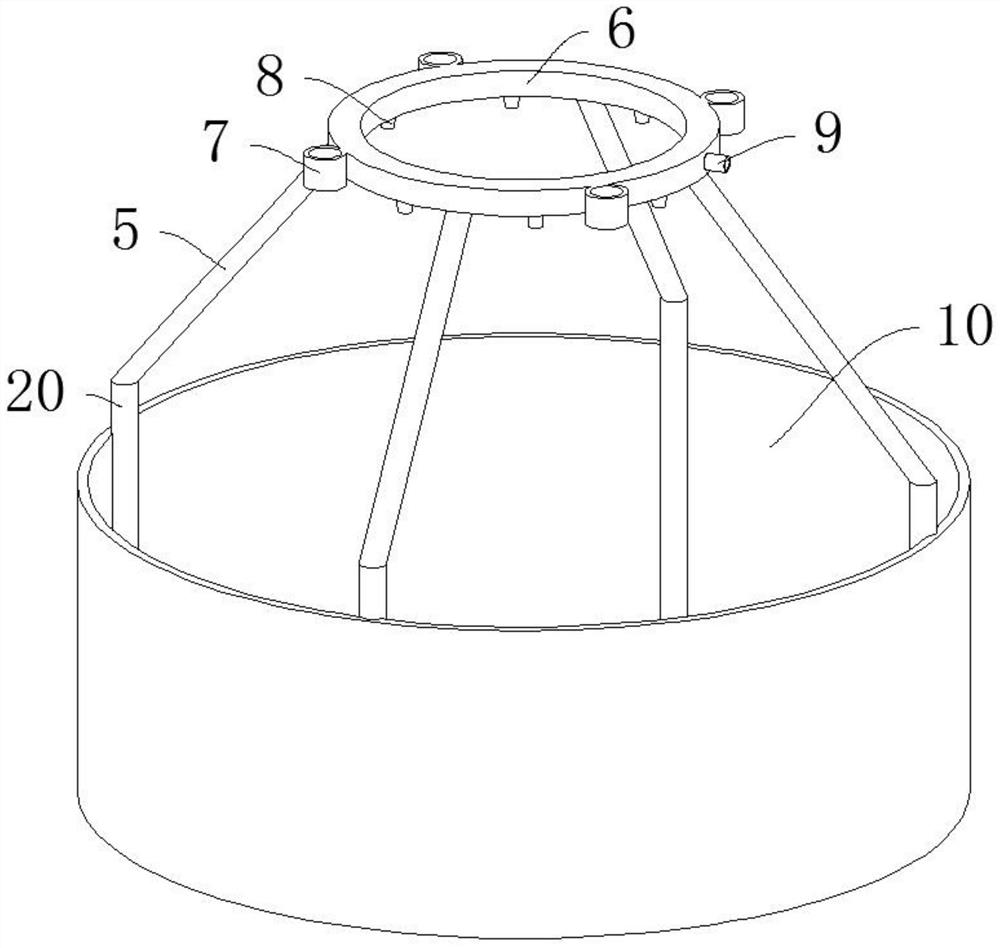

[0031] see Figure 1-Figure 6 , commercial concrete anti-solidification mechanical mixing device, including a support device 1, a stirring rod 2, a power device 3, the support device 1 includes a retaining ring 10, which prevents the outflow of concrete, and the retaining ring 10 is in the shape of a ring to protect the balance of the circumference, and the surrounding Four first ring seats 21 are evenly distributed on the inner circumference of the retaining ring 10, and the vertical struts 20 are fixed. The vertical struts 20 are installed in the first ring seat 21 to support the inclined struts 5, and the vertical struts 20 are provided with oblique supports. Rod 5, fixed support ring 6, support ring 6 is installed on the inclined pole 5, supports power unit 3, ring groove 22 is arranged in the support ring 6, accommodates water delivery pipe 23, and water delivery pipe 23 is installed in the ring groove 22, conveying For water liquid, there are 8 atomizing nozzles 8 evenly...

Embodiment 2

[0035] On the basis of above-mentioned embodiment:

[0036] The stirring rod 2 includes a support rod 11, a slot 12 is arranged on the top of the support rod 11, a locking nail 13 is installed on one side of the support rod 11, four cross bars 14 are evenly welded on the circumference of the support rod 11, and four cross bars 14 are uniformly welded below the cross bar 14. 6 vertical rods 15, the support rod 11 is used to fix the horizontal rod 14, the slot 12 is used to connect the transmission shaft 17, the locking nail 13 is used to lock the transmission shaft 17, the horizontal rod 14 is used to fix the vertical rod 15, the vertical rod 15 for stirring concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com