Key cooling demoulding mode

A key and demoulding technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problem of uneven material flow of key products, prolonged production cycle, increased demolding difficulty and defective demoulding rate of key products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

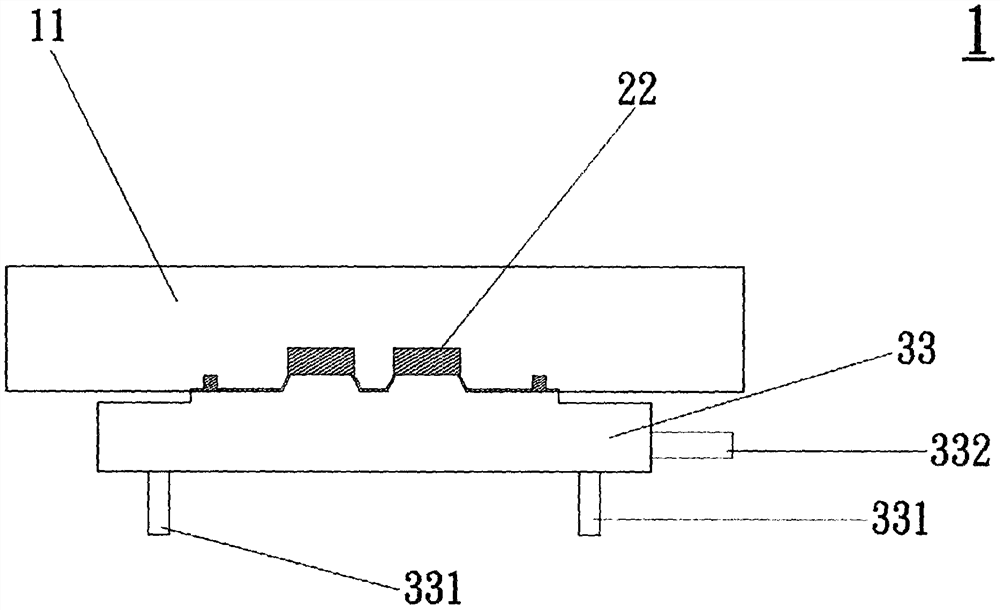

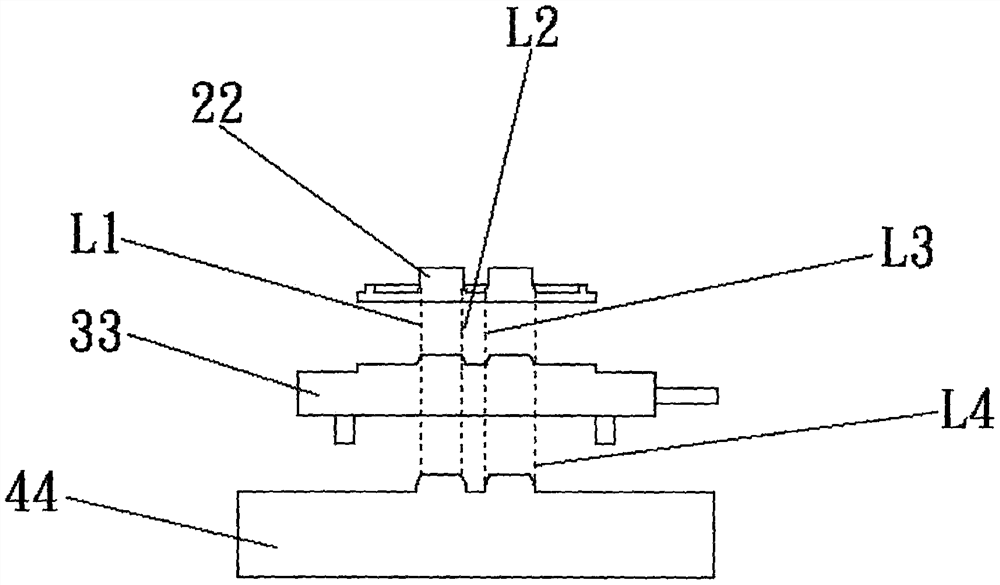

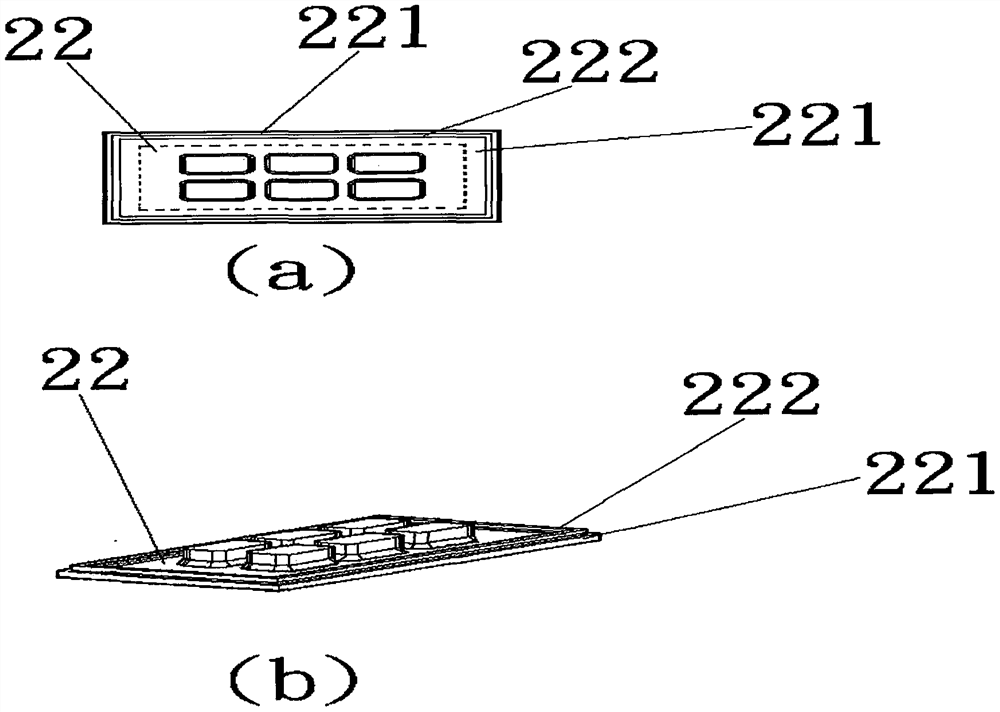

[0014] figure 1 It is a schematic diagram of the combination in the embodiment, and its implementation mode is: when the button product 22 of silicone rubber or rubber is heat-pressed or injection-molded, and the button product 22 is still trapped in the production master mold 11, the vacuum cooling demoulding fixture 33 Because it can be completely attached to the inner wall of the button product 22 and does not touch the production master mold 11, and the vacuum cooling demoulding fixture 33 is made of a material with high thermal conductivity, it can be quickly and only for rapid cooling The button product 22 part of the keypad product 22 is used to derive its high temperature and will not cool down the production master mold 11 because it does not touch the production master mold 11; and a cooling water inlet pipe 331 is provided in its vacuum cooling demoulding fixture 33 , the external cooling water can be imported into its vacuum cooling demoulding tool 33, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com