A kind of sealing and punching equipment for garbage bag production

A garbage bag and punching technology, which is applied in bag making, paper/cardboard containers, packaging, etc., can solve the problems of cumbersome operation steps and achieve high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

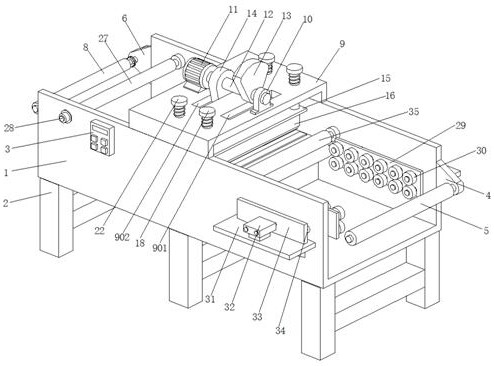

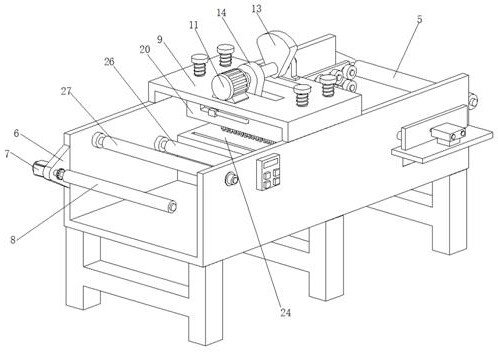

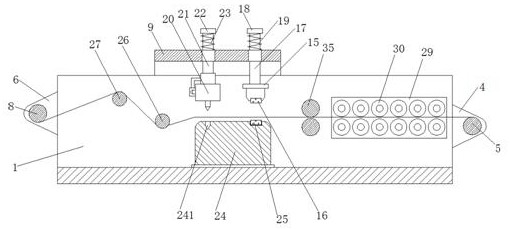

[0034] Example 1 introduces a kind of sealing and punching equipment for the production of garbage bags, refer to the appendix figure 1 and attached figure 2 , its main structure includes a U-shaped frame 1 , a corresponding support foot 2 is arranged on the lower surface of the U-shaped frame 1 , and a PLC control box 3 is arranged on the outer side of the U-shaped frame 1 . An unwinding mechanism is provided at the right end of the U-shaped frame 1 . Specifically, the unwinding mechanism includes a first fixing plate 4 fixedly connected to the right end of the U-shaped frame 1 , and an unwinding roller is rotatably connected to the first fixing plate 4 . 5, and the other end of the unwinding roller 5 is suspended in the air, so as to facilitate the feeding of the garbage bag roll material. A winding traction mechanism is provided at the left end of the U-shaped frame 1 . Specifically, the winding traction mechanism includes a second fixing plate 6 fixedly connected to the ...

Embodiment 2

[0040] Embodiment 2 discloses an improved sealing and punching equipment for garbage bag production based on Embodiment 1. Refer to the appendix. figure 1 The similarities between this embodiment 2 and embodiment 1 will not be described again, and the difference is that: this embodiment 2 is also provided with two front and rear sides of the U-shaped frame 1 between the unwinding mechanism and the top plate 9. The bag edge clamping device, specifically, the bag edge clamping device includes a rectangular plate 29 arranged in the U-shaped frame 1, and a plurality of upper and lower symmetrical clamping wheels 30 are arranged on the rectangular plate 29. The outer side is provided with a mounting plate 31, and the upper surface of the mounting plate 31 is provided with a push device 32. Specifically, the push device 32 can also be selected from an air cylinder or a hydraulic cylinder, and a push plate 33 is connected to the extension shaft of the push device 32 to push The plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com