A temperature control method for a preheating antifreeze system of a wet cooling tower

A temperature control method and technology of antifreeze system, which are applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc. Problems such as the deviation of air temperature and water temperature out of the tower from the target optimal value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

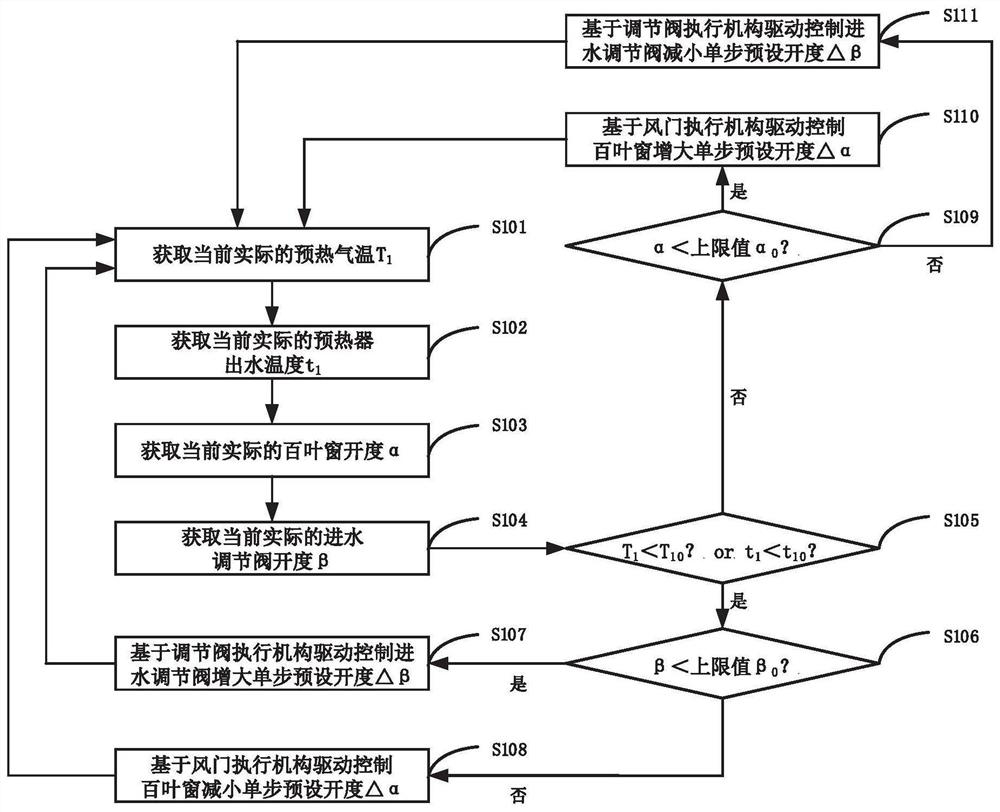

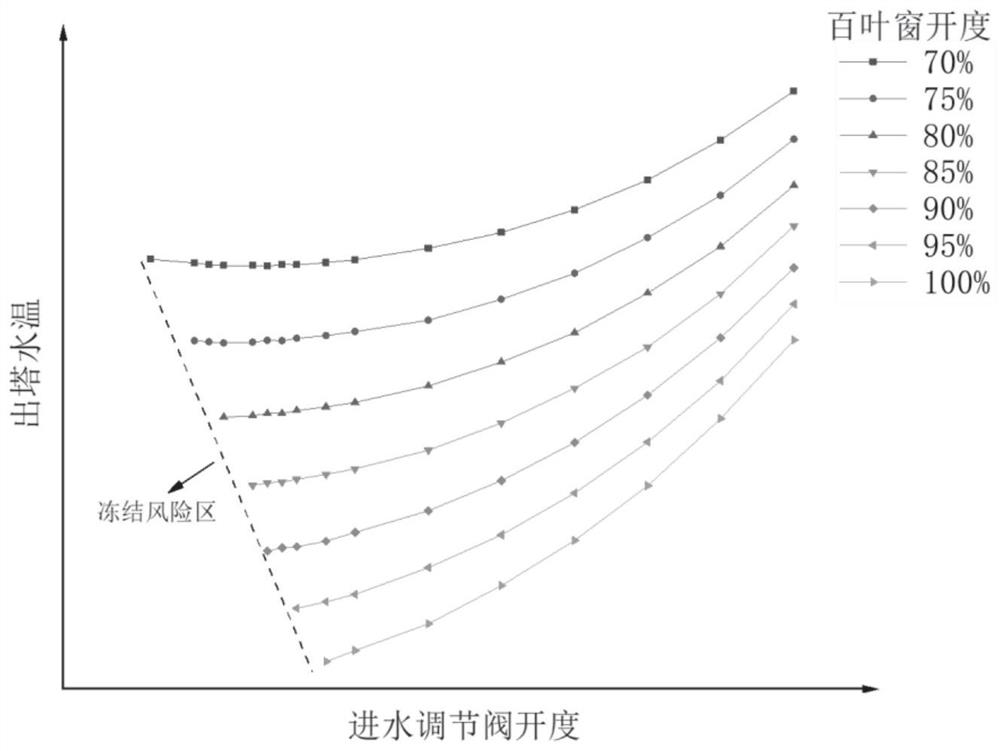

[0044] Such as figure 2 As shown, the temperature control method of the preheating antifreeze system of the wet cooling tower in this embodiment is used for the control of the preheater air intake louver type damper 120 and the water inlet regulating valve 320 of the preheating antifreeze system. Under the premise of antifreeze, the cooling water temperature of the tower is the lowest.

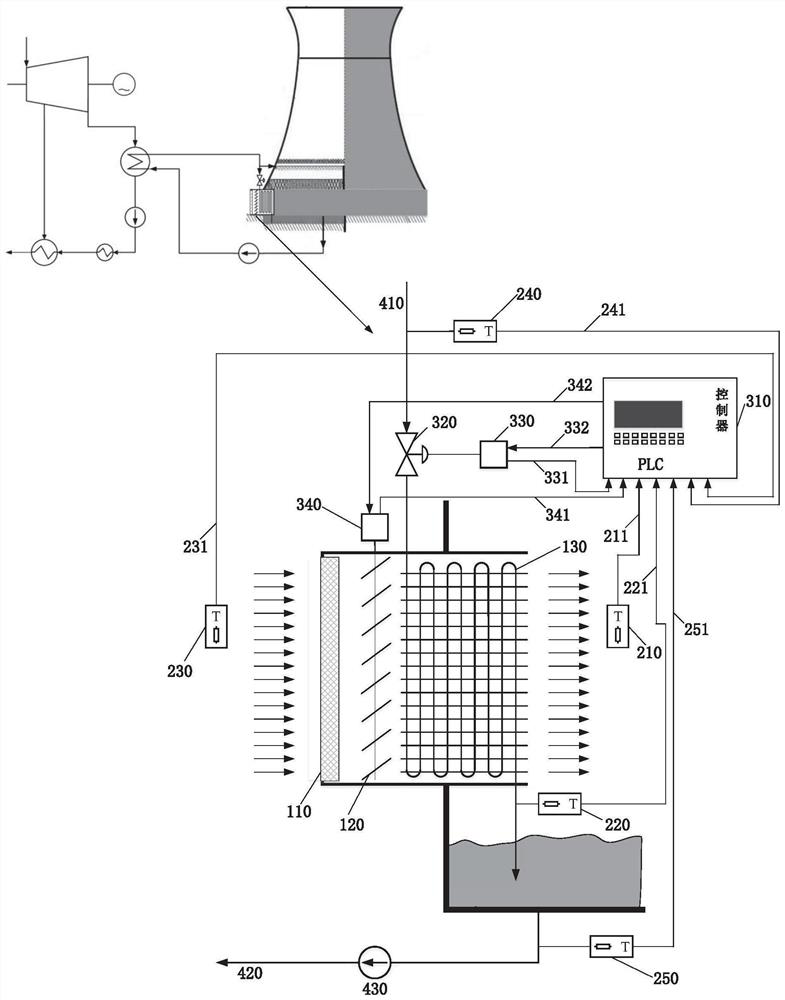

[0045] The based control system is a preheating antifreeze system installed at the air inlet of the cooling tower. The control system includes: air preheater 130, louver-type damper 120, damper actuator 340, water inlet adjustment valve 320, valve actuator 330 , ambient temperature sensor 230 , preheating air temperature sensor 210 , outlet water temperature sensor 220 , tower inlet water temperature sensor 240 , tower outlet water temperature sensor 250 , and PLC controller 310 .

[0046] Temperature control includes combined control of preheating air temperature, preheater outlet water tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com