A kind of inorganic salt electrochromic thin film and its preparation method and application

An electrochromic, inorganic salt technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of limitations, high energy consumption, and inapplicability of flexible substrates, and achieve the effect of protecting high temperature burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

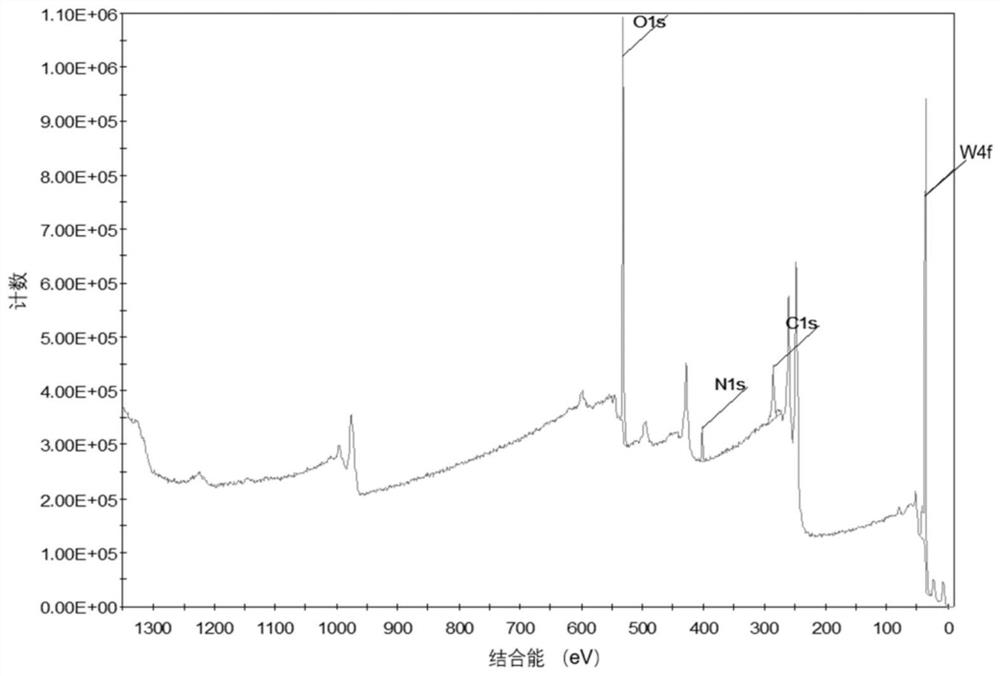

[0034] (1) Mix ammonium metatungstate, conductive silver nanoparticles, deionized water, and PVA in a certain proportion to prepare a precursor solution. The concentration of ammonium metatungstate in the solution is 1mol / L, and the diameter of conductive silver nanoparticles is 30 nm. The resistivity of deionized water is 15MΩ m, the mass ratio of conductive silver nanoparticles to tungsten element (W) in the film is 1.5:400, and the mass ratio of crystallization inhibitor PVA to tungsten element (W) in the film is 1:73 .

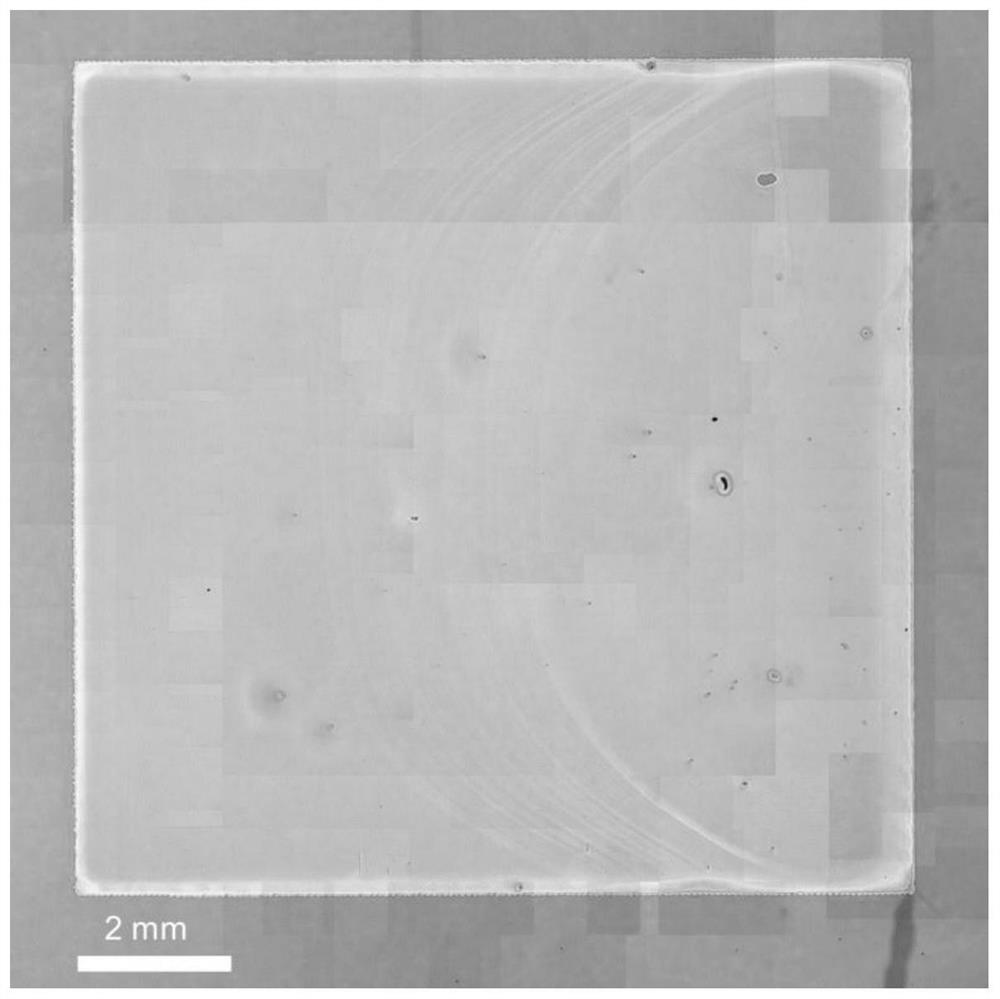

[0035] (2) Prepare the precursor solution obtained in step 1 to form a film on the conductive flexible substrate by inkjet printing process. The printing process parameters are as follows: the distance between the nozzle and the substrate is 3mm, the voltage of the piezoelectric ceramic is 35V, and the substrate temperature is 25 °C, the inkjet interval is 10 μm, the area of the film printed in Example 1 is 1 cm×1 cm, and the thickness of the film prepar...

Embodiment 2

[0041] It is basically the same as steps (1) to (4) of Example 1, except that in step (1): the concentration of ammonium metatungstate is 0.7 mol / L, and the crystallization inhibitor is PEO. The film prepared by printing in Example 2 has an area of 1 cm×1 cm and a thickness of 55.4 nm. Inorganic salt (NH 4 ) x W y o (6y+x) / 2 ·nH2 In O x / y=0.39, n=0.4.

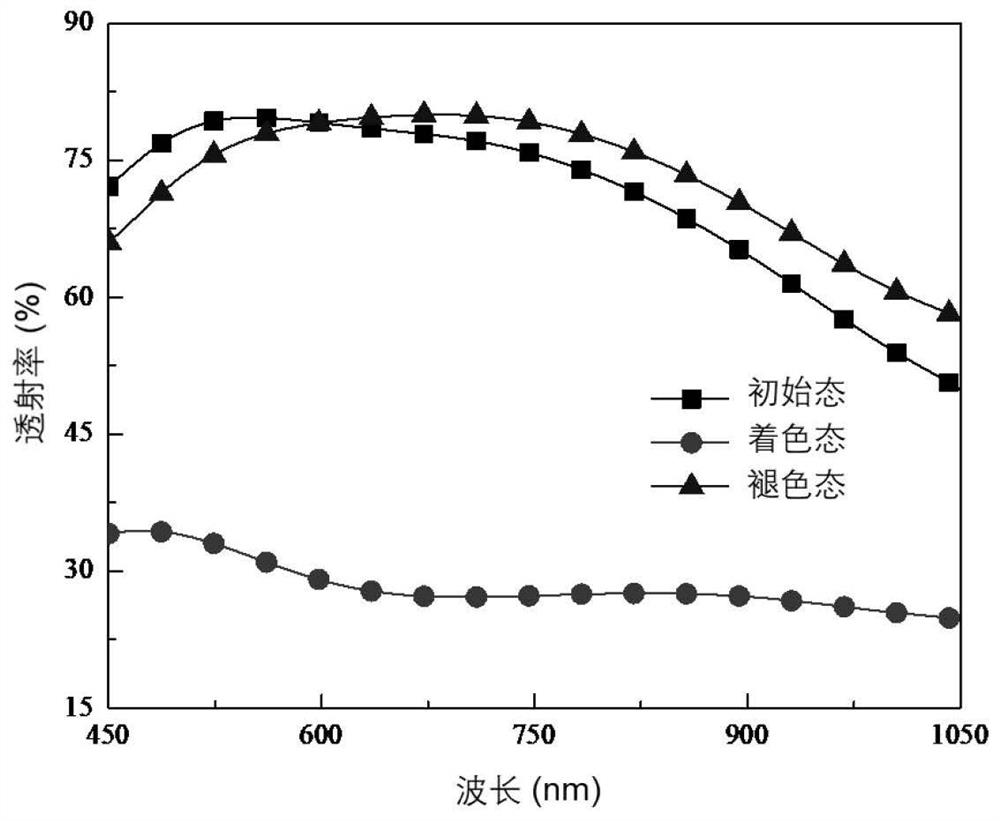

[0042] In the LiClO of 1mol / L the gained film of embodiment 2 4 The electrochromic test was carried out in / PC electrolyte, and the driving voltage was ±1.5V. The initial state transmittance and faded state transmittance of the film are about 85% (@600nm), the colored state transmittance is about 38% (@600nm), and the optical modulation ability reaches 47% (@600nm).

Embodiment 3

[0044] It is basically the same as steps (1), (3)-(4) of Example 1, except that step (2): the precursor solution obtained in step 1 is prepared into a film by inkjet printing process, and the printing process parameters are as follows: nozzle The distance to the substrate is 1mm, the voltage of the piezoelectric ceramic is 40V, the temperature of the substrate is 25°C, and the inkjet interval is 10μm. The area of the film printed in Example 3 is 1cm×1cm. The thickness is 75.2nm. Inorganic salt (NH 4 ) x W y o (6y+x) / 2 ·nH 2 In O x / y=0.49, n=3.5.

[0045] In the LiClO of 1mol / L the gained film of embodiment 3 4 The electrochromic test was carried out in / PC electrolyte, and the driving voltage was ±1.5V. The initial state transmittance and faded state transmittance of the film are about 79% (@600nm), the colored state transmittance is about 25% (@600nm), and the optical modulation ability reaches 54% (@600nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com