An improved generative adversarial network based image defect segmentation method for eddy current inspection of aluminum plates

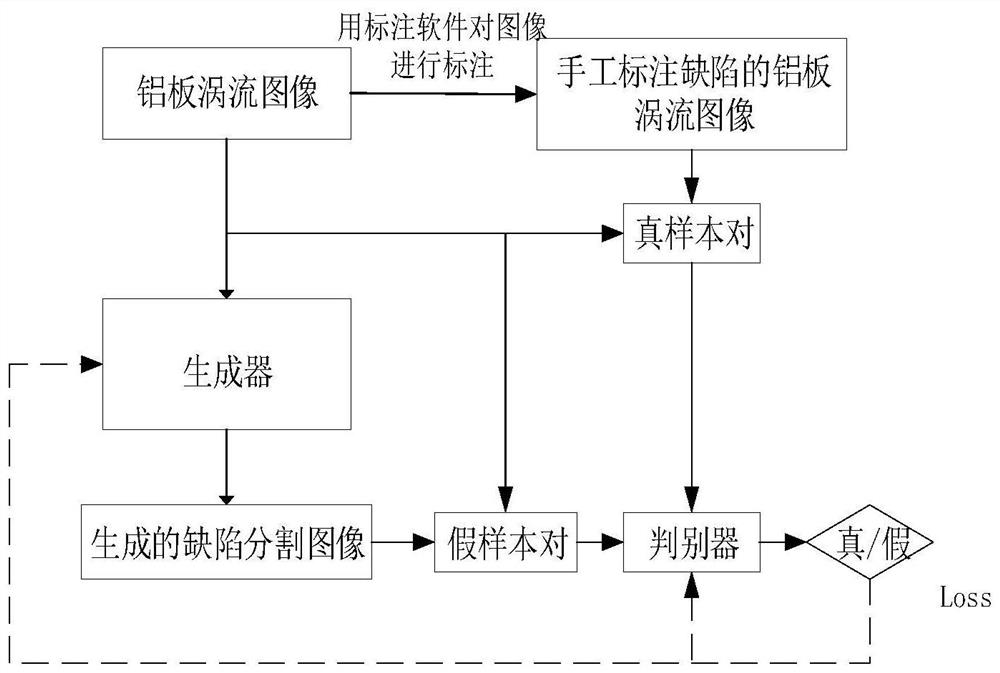

A technology for image detection and eddy current detection, which is applied in image analysis, biological neural network models, image data processing, etc., can solve the problems of difficult identification of image edge areas, enhanced image segmentation algorithm, and segmentation effect to be improved, so as to improve accuracy , high recognition ability, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

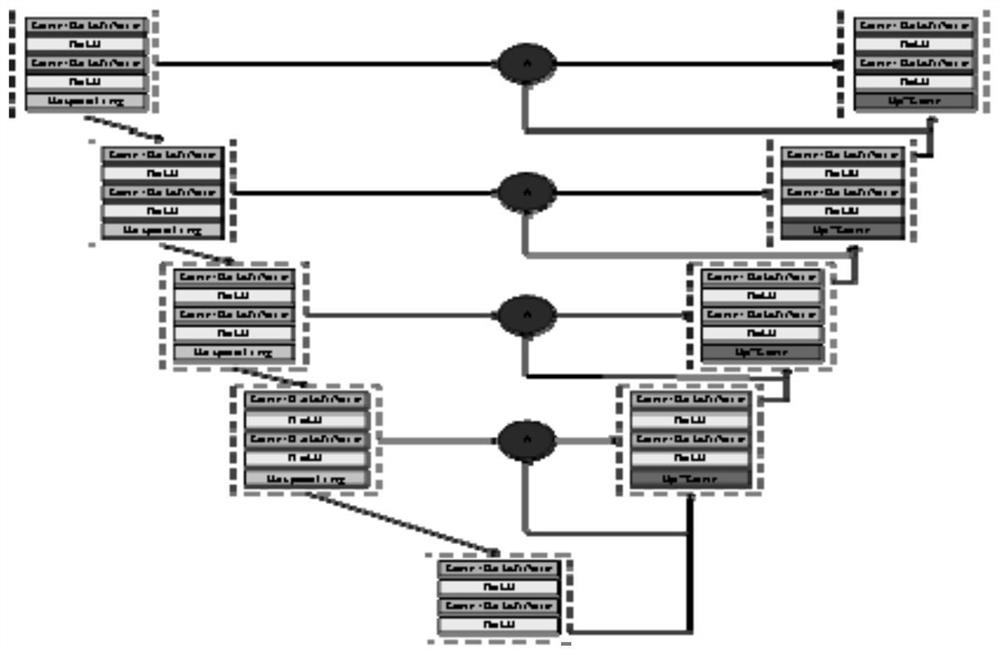

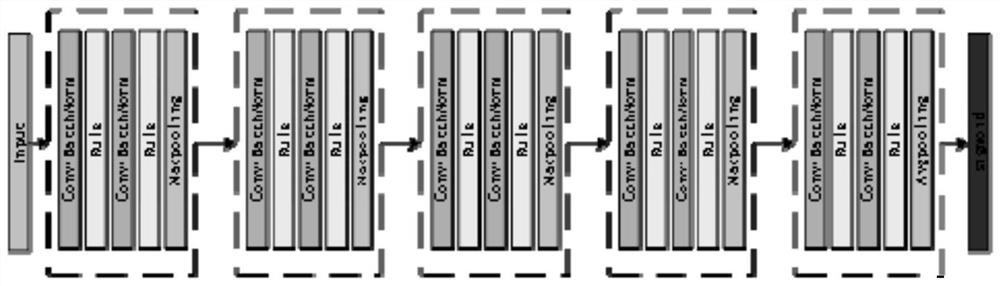

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Experiment The eddy current detection defect image of aluminum plate was tested, and the threshold segmentation Otsu algorithm and the common deep learning algorithm fcn-8s model, fcn-32s model, and U-net model were compared with the algorithm in this paper. Comparison of the segmentation effects of various algorithms for type defects such as Figure 5 shown.

[0042] Specific steps are as follows:

[0043] Step1: Acquisition of image data for eddy current inspection of aluminum plate;

[0044] The eddy current inspection image of the aluminum plate is used to detect the fatigue crack in the 3mm thick 6061 aluminum plate surface in a grooved way to simulate the metal to be tested by the eddy current inspection platform. The eddy current inspection probe detects defects on the surface of the aluminum plate by means of C-scanning. The eddy current testing experimental platform is designed and built by the School of Mechanical and Electrical Engineering, Chin...

Embodiment 2

[0064] Example 2: In actual production, eddy current testing is easily interfered by working conditions, working environment, and human factors, resulting in the phenomenon that there are different degrees of noise interference in defect areas of eddy current images. In order to further verify the robustness of the method in this paper, comparative experiments under different working conditions were also carried out in this experiment. In order to simulate different working conditions, different degrees of Gaussian white noise are added to the samples, and the signal-to-noise ratios are 50db, 60db, and 70db.

[0065] Specific steps are as follows:

[0066] Step1: Acquisition of image data for eddy current inspection of aluminum plate;

[0067] The eddy current inspection image of the aluminum plate is used to detect the fatigue crack in the 3mm thick 6061 aluminum plate surface in a grooved way to simulate the metal to be tested by the eddy current inspection platform. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com