Grain stone-removing jigger

A stone jig and grain technology, applied in the field of jigs, can solve problems such as the impact of production equipment, achieve better efficiency, uniform distribution, and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

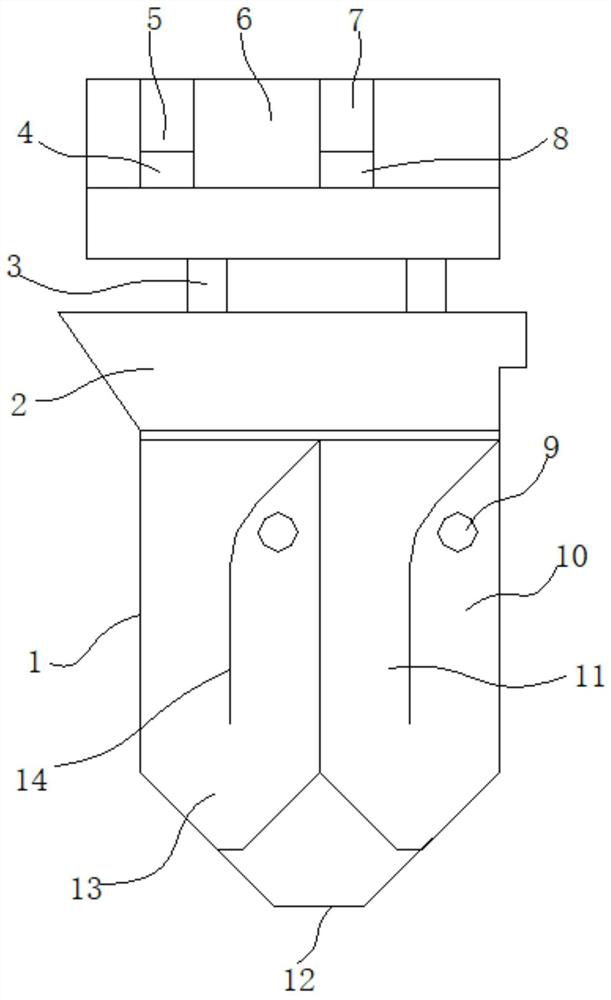

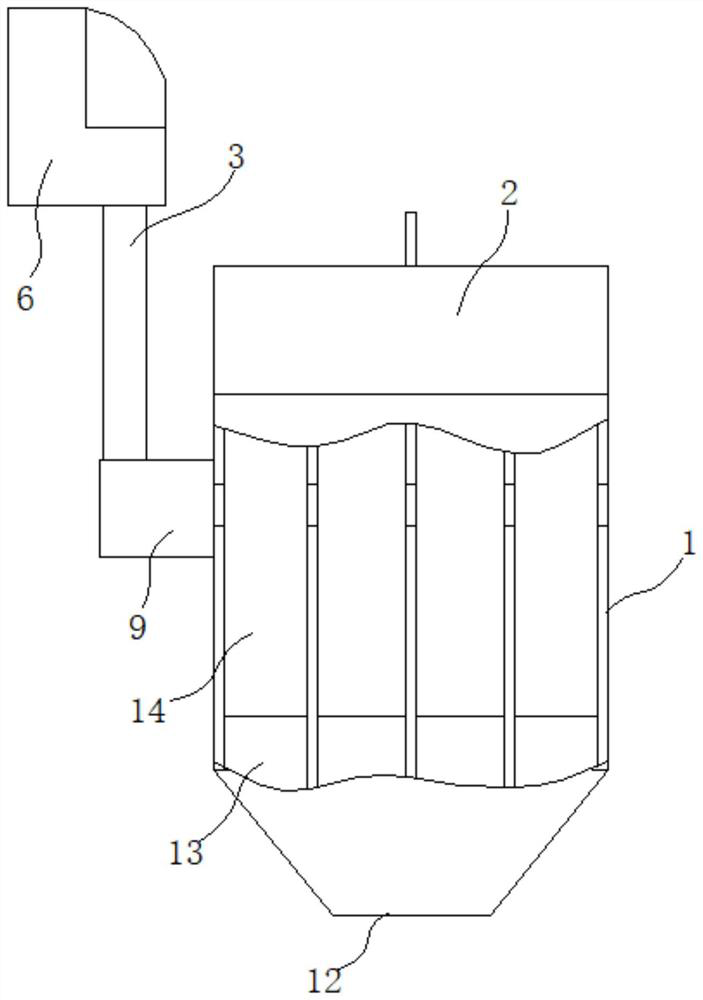

[0039] Such as figure 1 and figure 2 As shown, a grain stone removal jig machine includes a compressed air source, a bellows 6 and a jigging chamber 1 with a screening stone removal groove 2 at the top and a sieve material outlet 12 at the bottom;

[0040] The bellows 6 is provided with an air inlet end 4, an air outlet end 7 and an air supply end 3, an air inlet valve 5 is arranged on the air inlet end 4, an air outlet valve 8 is arranged on the air outlet end 7, and the compressed air source passes through the air duct Connect to the air inlet 4;

[0041] The jigging chamber 1 is provided with a ventilation duct 9, one end of the ventilation duct 9 is blocked, and the other end extends out of the jigging chamber 1, and is connected to the air supply end 3 through the air duct;

[0042] A plurality of independent jigging chambers 13 are evenly distributed in the jigging chamber 1. The top of each independent jigging chamber 13 is connected to the screening stone removal ta...

Embodiment 2

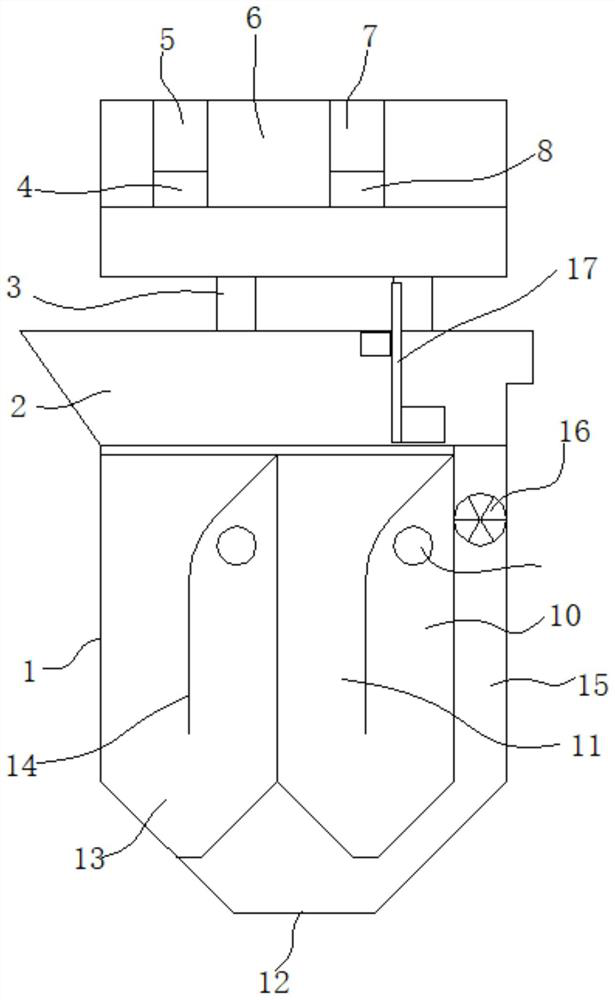

[0050] On the basis of Example 1, such as image 3As shown, the side wall of the jigging chamber 1 is provided with a sorting impurity channel 15 with two ends respectively connected to the discharge port 12 of the sieved material and the discharge end of the screening and stone removal tank 2, and the sorting impurity channel 15 is provided with a discharge device, a bed thickness detection device 17 is arranged in the screening stone removal tank 2, the bed thickness detection device 17 and the discharge device are respectively electrically connected to the controller, and the controller obtains the bed thickness signal fed back by the bed thickness detection device 17 to control The discharge device operates to discharge the sorting impurities in the jigging chamber 1 through the sorting impurity channel 15 .

[0051] Preferably, the bed thickness detection device 17 adopts a bed thickness sensor.

[0052] Preferably, the discharge device adopts a discharge impeller 16 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com