Plant screening device

A screening and plant technology, applied in the agricultural field, can solve the problems of waste of resources, difficult processing, and easy separation, and achieve the effects of saving resources, improving screening efficiency, and avoiding manual injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

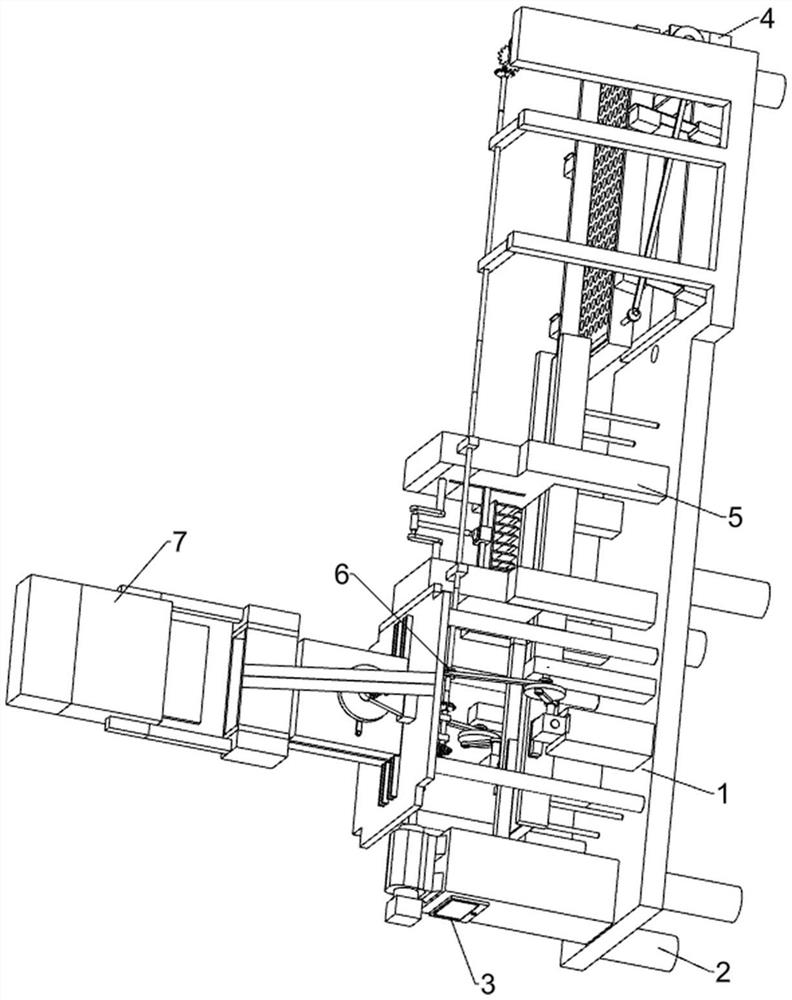

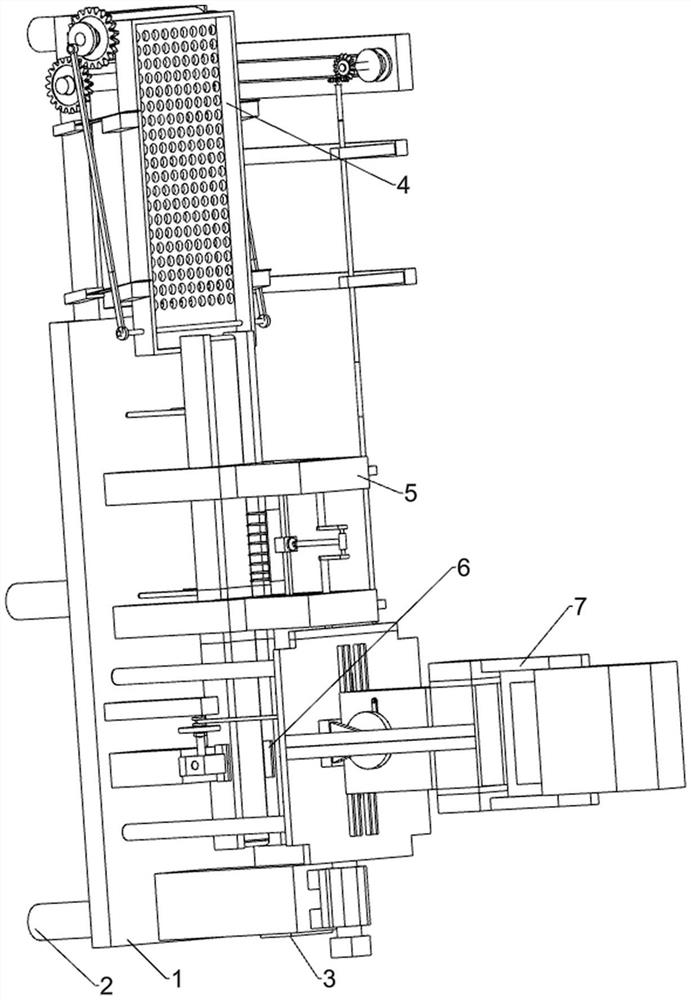

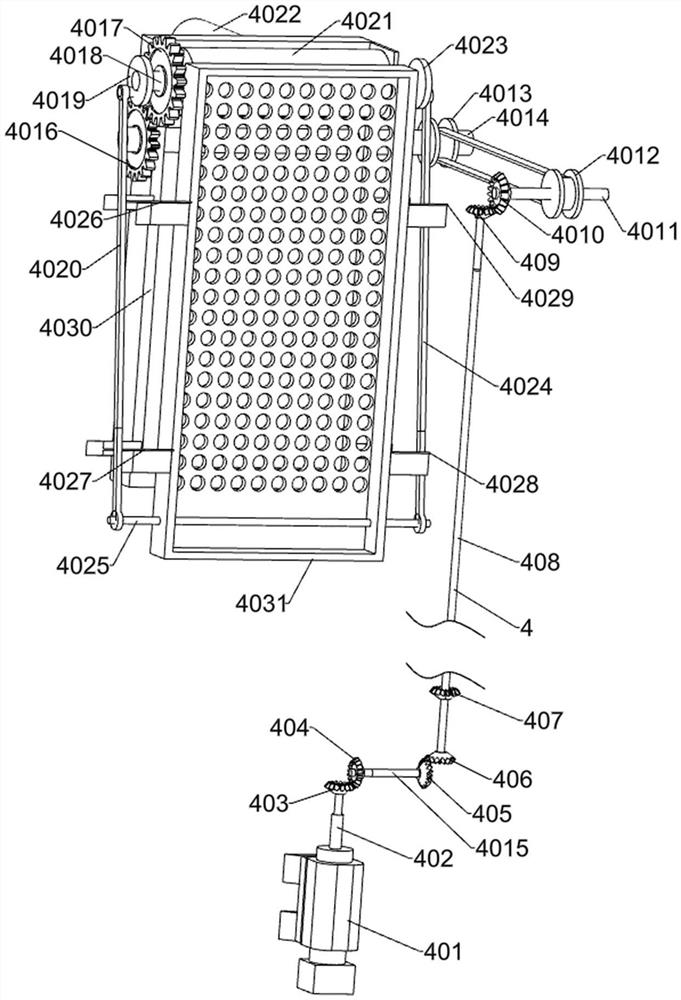

[0026] A plant sorting device, such as Figure 1-6 As shown, it includes a workbench 1, a bottom column 2, a control panel 3, a screening mechanism 4, a segmentation mechanism 5, a limit mechanism 6 and a feeding mechanism 7; the workbench 1 and the bottom column 2 are welded; the workbench 1 Bolt connection with control panel 3; workbench 1 is connected with screening mechanism 4; workbench 1 is connected with section mechanism 5; workbench 1 is connected with limit mechanism 6; Connection; the screening mechanism 4 is connected with the segmentation mechanism 5; the screening mechanism 4 is connected with the limit mechanism 6; the screening mechanism 4 is connected with the feeding mechanism 7; the segmentation mechanism 5 is connected with the limit mechanism 6; The limit mechanism 6 is connected with the feeding mechanism 7 .

[0027] Working principle: when the device is in use, the device is first opened and adjusted through the control panel 3 on the workbench 1 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com