Rotary disc saw blade for aluminum alloy machining

An aluminum alloy and alloy technology, which is applied in the field of aluminum alloy processing turntables, can solve the problems of angle change, uneven material incision, and the angle adjustment part is not locked, and achieves the effect of precise angle adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Such asfigure 1 ,figure 2 ,image 3 ,Figure 5 ,Figure 6 ,Figure 7 ,Picture 9 withPicture 10Shown

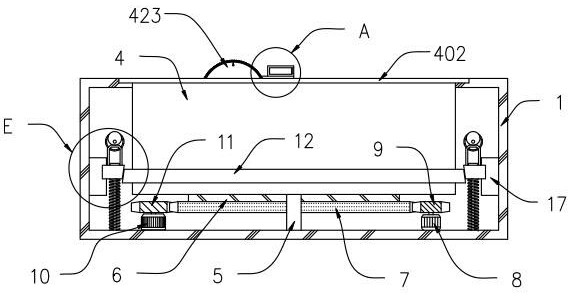

[0038]figure 1 Is a schematic diagram of the overall structure of the present invention;

[0039]figure 2 It is a top view of the overall structure in the present invention;

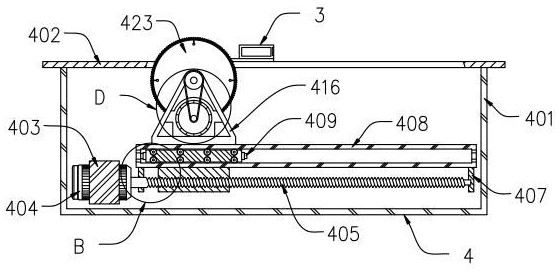

[0040]image 3 It is a schematic diagram of the internal structure of the cutting device assembly of the present invention;

[0041]Figure 5 Is a schematic diagram of the overall structure of the sliding track in the present invention;

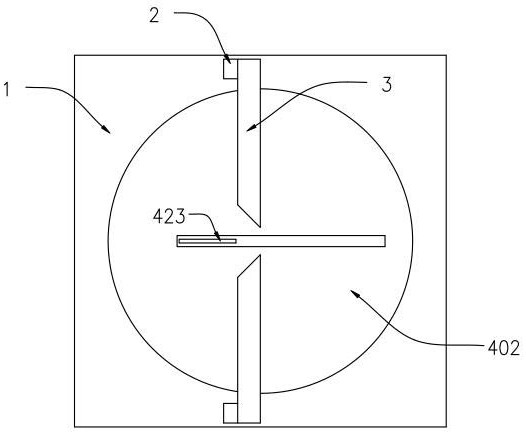

[0042]Figure 6 In the present inventionfigure 1 Schematic diagram of the structure of A;

[0043]Figure 7 In the present inventionimage 3 Schematic diagram of the structure at B;

[0044]Picture 9 In the present inventionimage 3 Schematic diagram of the D location;

[0045]Picture 10In the present inventionfigure 1 Schematic diagram of the structure at E.

[0046]A turntable for aluminum alloy processing includes a device casing 1. A heightening pad 2 is fixedly connected to the outer side of the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com