Middle correcting error guidance system

A guidance system and circuit technology, applied in the direction of control using feedback, can solve the problems of low control accuracy and single function, and achieve the effects of flexible installation, high deviation correction accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

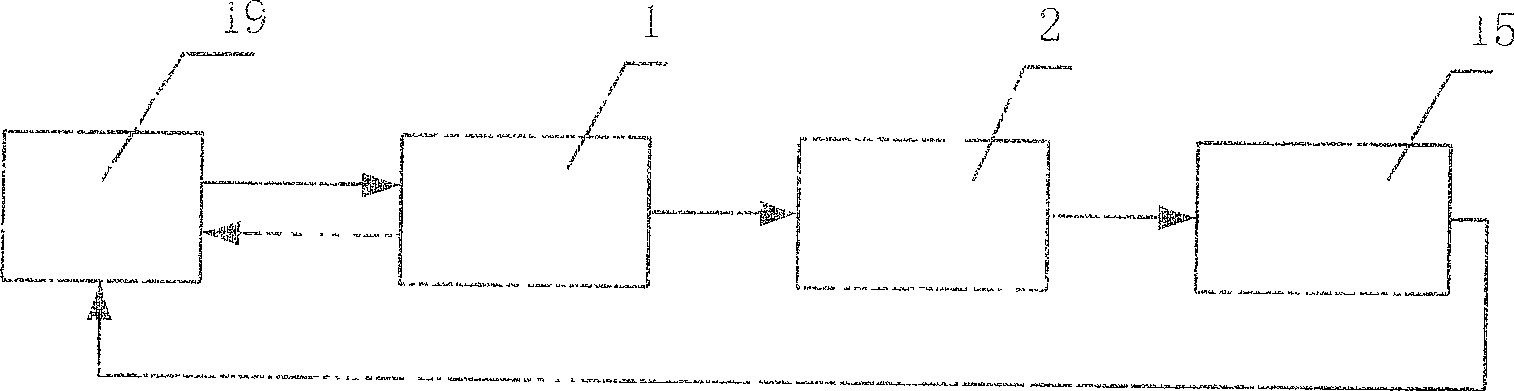

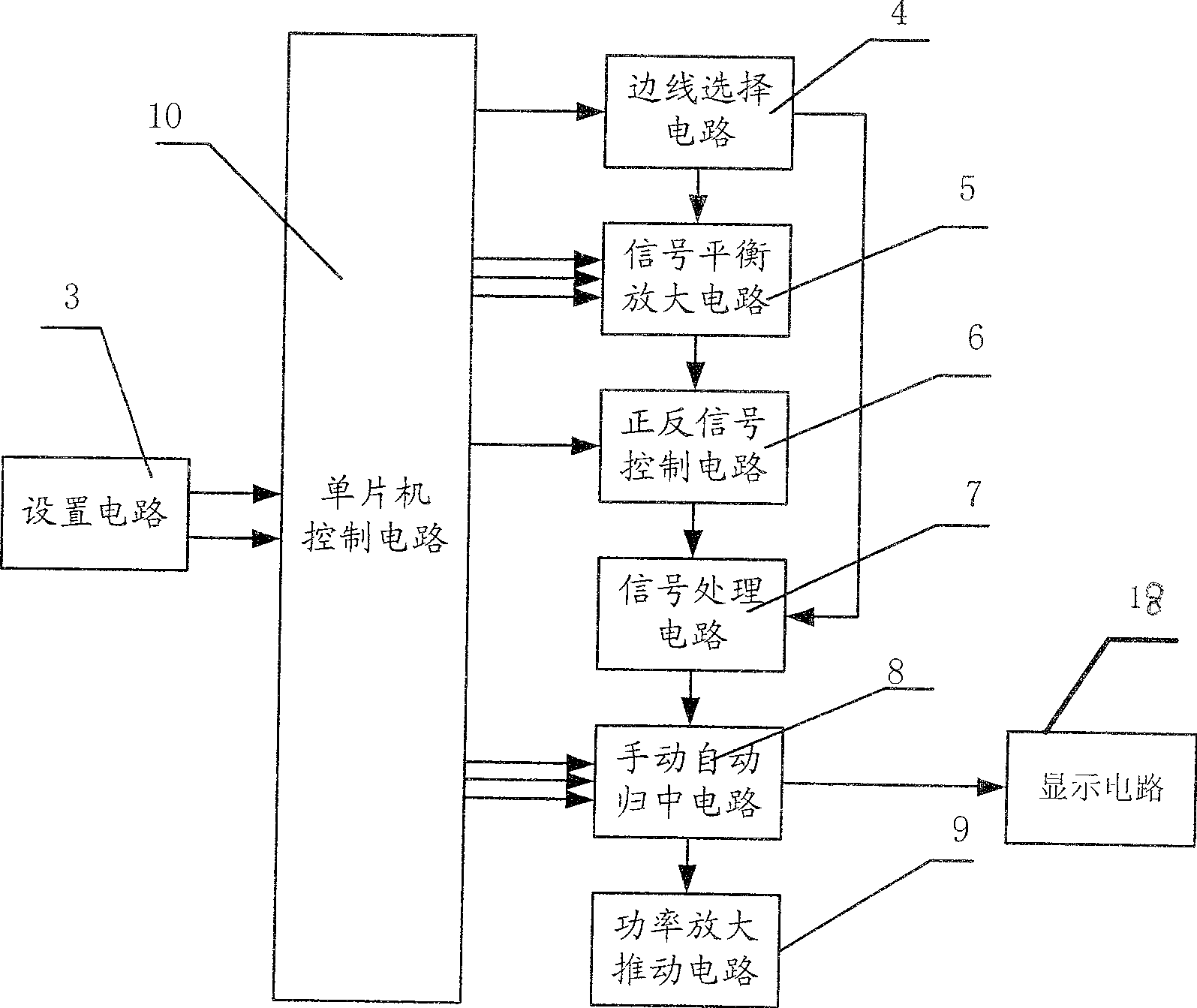

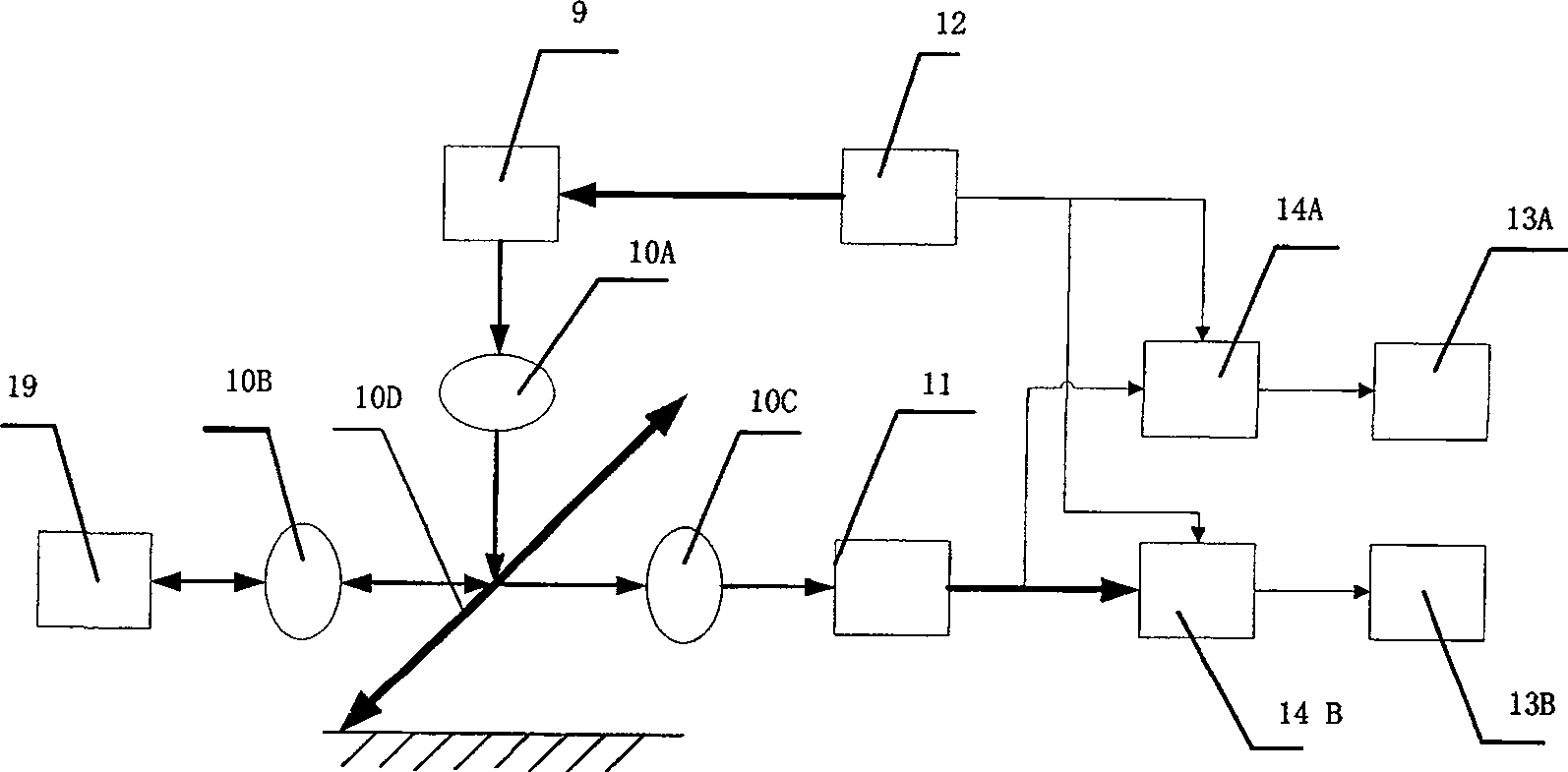

[0034]see figure 1 , figure 2 and image 3 , an intermediate rectifying and guiding system, composed of a photoelectric sensor 1, a microcomputer proportional controller 2 and an intermediate rectifying and guiding device 15; the photoelectric sensor 1 detects the edge of the mark position of the coil material 19, and reads the actual position of the mark position of the coil material 19 The offset with the set reference, and convert the offset into an electrical signal and input it to the microcomputer proportional controller 2; the microcomputer proportional controller 2 receives the electrical signal output by the photoelectric sensor 1, amplifies the electrical signal, and amplifies the efficiency and power Output to the intermediate deviation-correcting guide device 15; the intermediate deviation-correcting guide device 15 corrects the mark position of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com