Fuel nozzle processing method, fuel nozzle

A technology of fuel nozzles and processing methods, which is applied in the direction of fuel injection devices, charging systems, machines/engines, etc. It can solve the problems of oil leakage rate, high oil leakage rate, low part qualification rate, and many maintenance times, and achieve repair Rate reduction, high processing efficiency, avoiding the effects of parts rework or scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

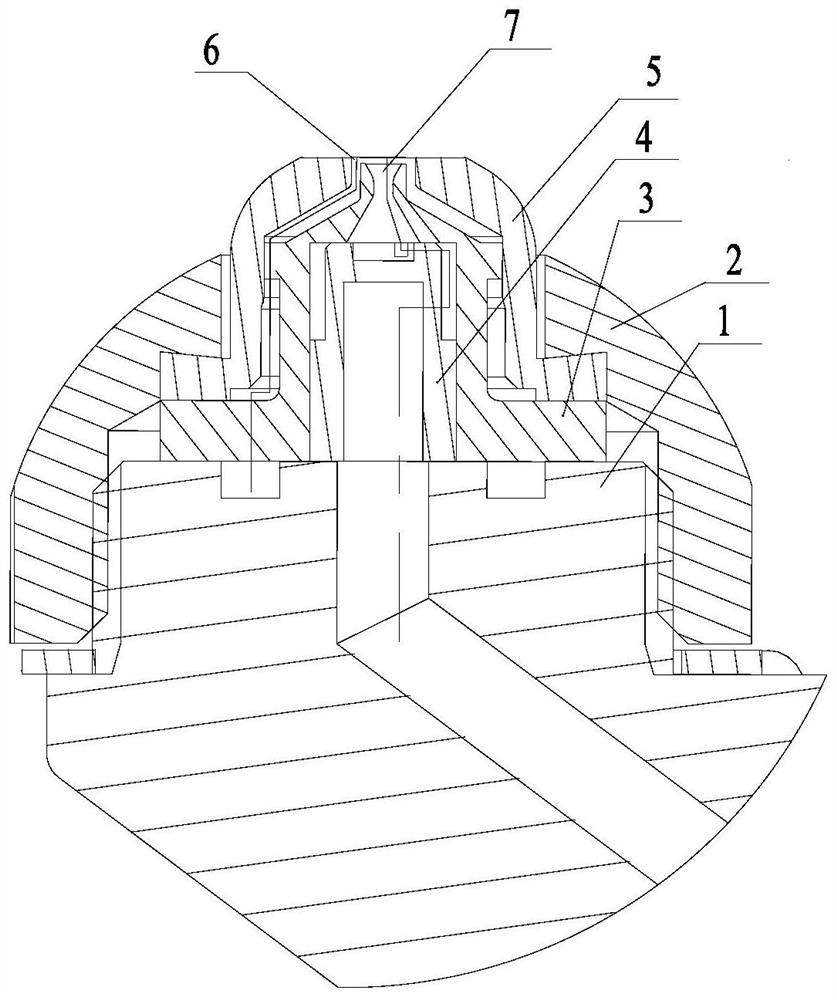

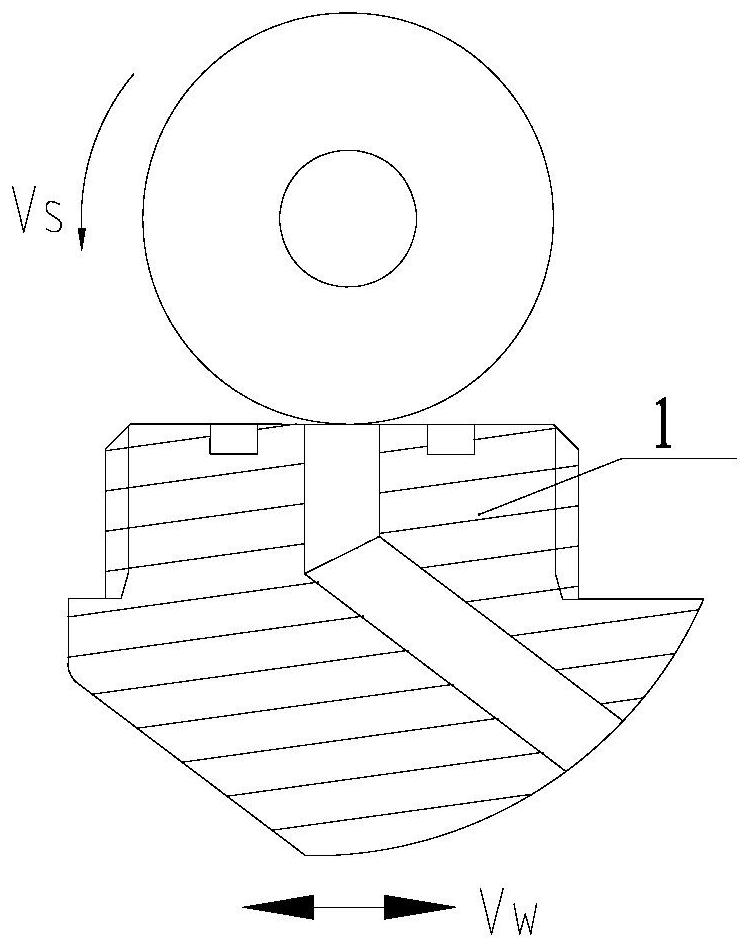

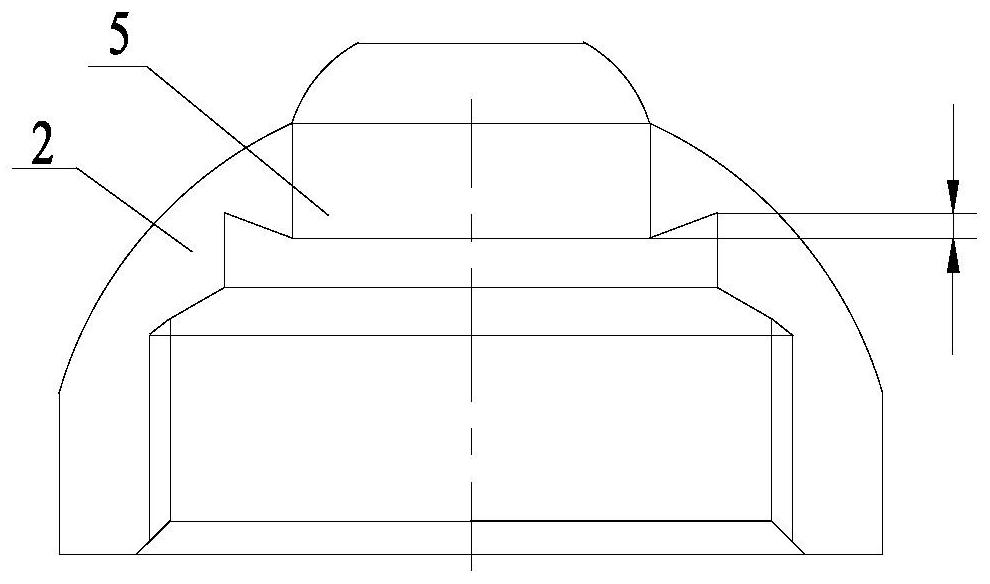

[0028] figure 1 is a schematic diagram of the preferred fuel nozzle of the present invention; figure 2 It is a schematic diagram of the grinding process of the preferred fuel seat graphite grinding wheel of the present invention; image 3 It is a schematic diagram of the inverted cone structure of the preferred main nozzle of the present invention.

[0029] Such as figure 1 As shown, a preferred embodiment of the present invention provides a method for processing a fuel nozzle, comprising the following steps:

[0030] S1. Process the nozzle seat 1 with the first oil passage 6 and the second oil passage 7. The outer wall of the nozzle seat 1 is processed with external threads that match the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com