Novel corrugated pipe machining equipment and using method

A technology for processing equipment and corrugated pipes, applied in the field of corrugated pipe processing equipment, can solve the problems of complicated rolling process, large area of production equipment and small area, so as to improve the working mode and efficiency and reduce the work of operators. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

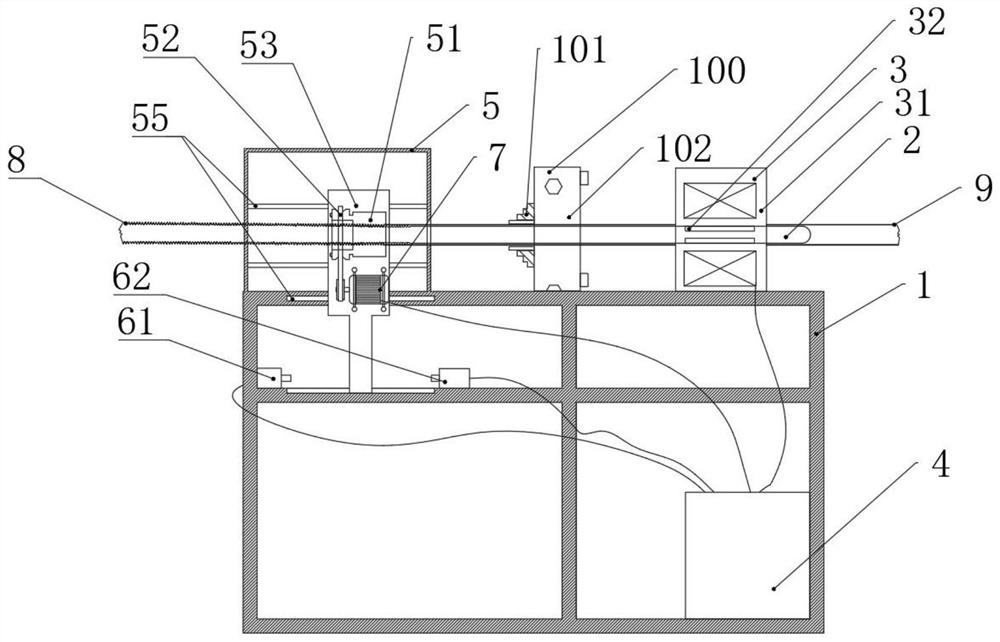

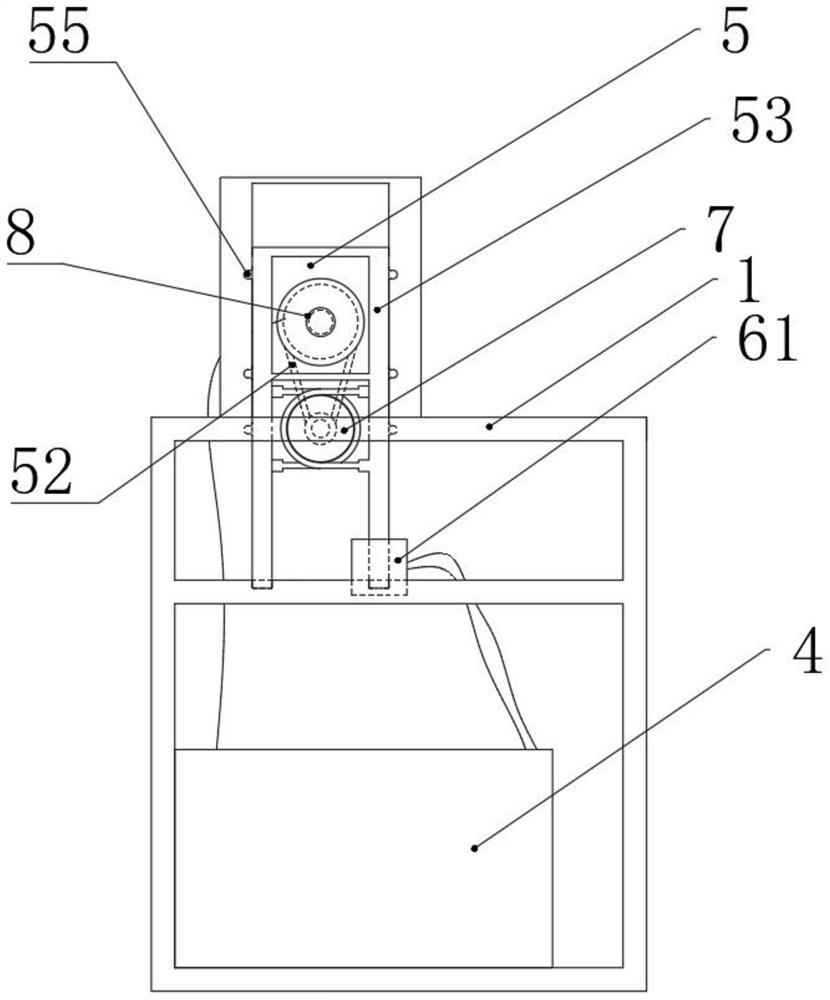

[0055] Embodiment 1: Through the arrangement of the above scheme, the energized magnetic drive device 3 acts on the magnetic force of the permanent magnet 32 of the main roller 2 through the electromagnetic coil 31, and is used to drive the main roller 2 to rotate and fix in the circumferential direction. When the main roller 2 rotates, the threaded sleeve 51 is locked and fixed in the circumferential direction under the control of the motor 7. At this time, based on the thread fit between the main roller 2 and the threaded sleeve 51, the slider 53 moves away from the magnetic drive device 3 at a constant speed. At the same time, because the threaded sleeve 51 does not rotate, the bellows 8. Restricted by the thread, the sliding part 53 moves to realize the feeding function; when the sliding part 53 is driven by the threaded sleeve 51 to move to one end of the stroke, and the light touch switch K61 is triggered, the equipment switches to the working state, and the magnetic dri...

Embodiment 2

[0056] Embodiment 2: on the basis of embodiment 1, motor 7 is set to stepping motor, utilizes the control device 4 that can control the work of stepping motor to be connected with stepping motor, saves light touch switch control, by the mode of program control, Accurate the rotation angle and the number of turns of the stepping motor to realize the size of a reciprocating stroke bellows 8. Compared with Embodiment 1, the device can be adjusted more conveniently by setting the program, and the sliding part 53 and the bracket 1 can also be adjusted. Fixed setting, the magnetic drive device 3 is set to move axially along the main roller 2 .

[0057] The design of the corrugated pipe processing equipment in this scheme is scientific, reasonable and simple, and the required floor area is small. It can be freely adjusted based on the waveform, wall thickness, diameter, length and other specifications of different corrugated pipes produced on demand. It is driven by a magnetic drive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com