Carrying robot for intelligent warehouse

A technology for handling robots and warehouses, applied in the field of handling robots, which can solve problems affecting safety, shelf shaking, accidents, etc., and achieve the effects of reducing contact area, easy detachment, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

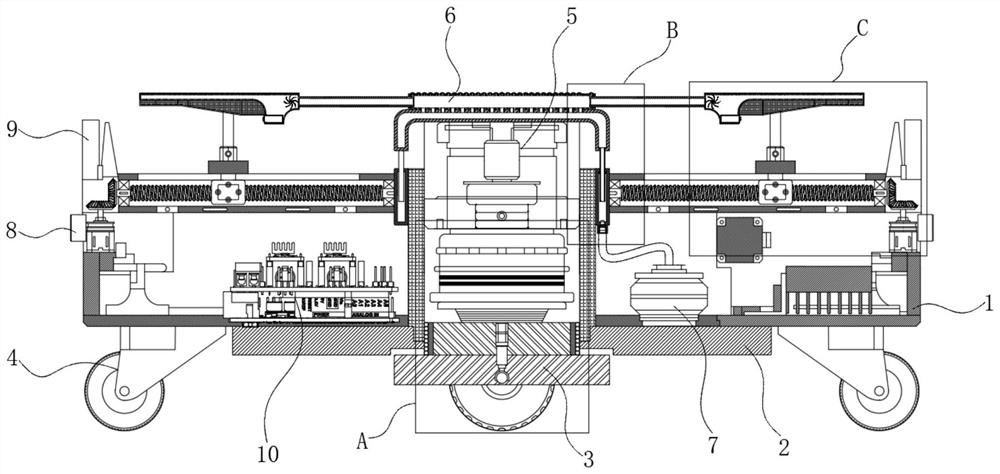

[0033] refer to figure 1 , the present invention provides a technical solution: a handling robot for an intelligent warehouse, including a chassis 1, a drive assembly 3, a tray assembly 6 and a controller 10, wherein a plurality of million To the wheel 4, a controller 10 is fixed on the inner side of the chassis 1 for controlling the operation of the internal components;

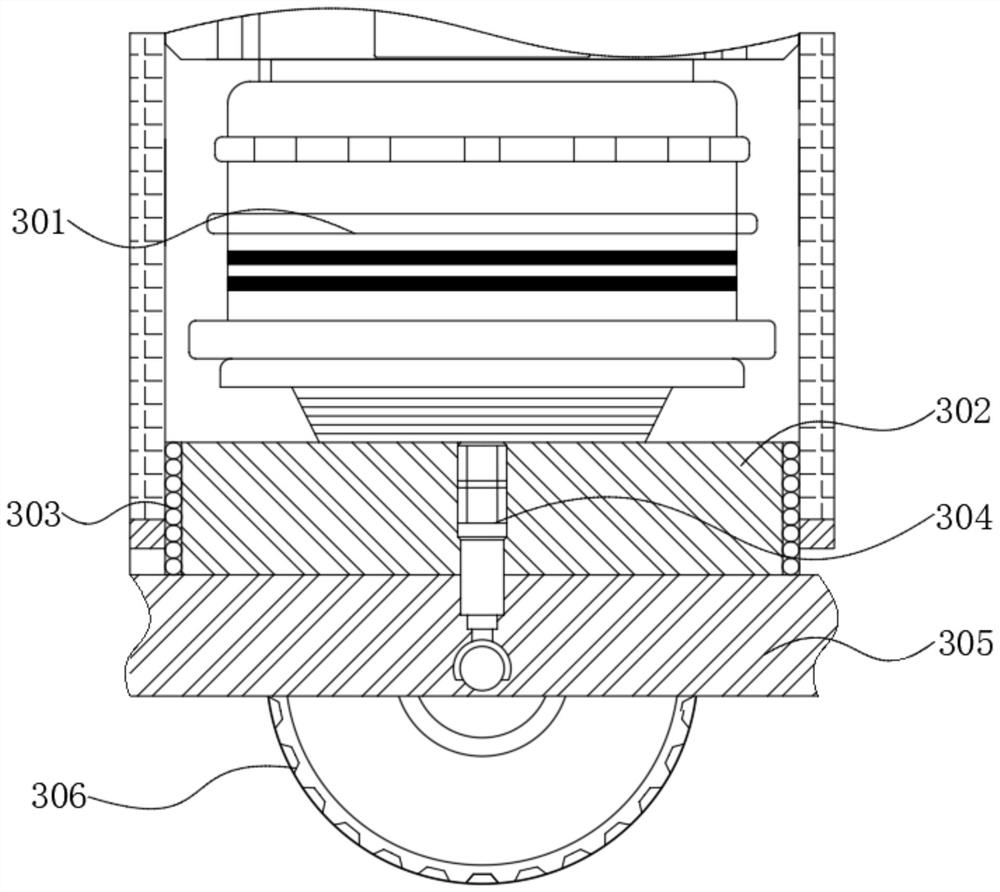

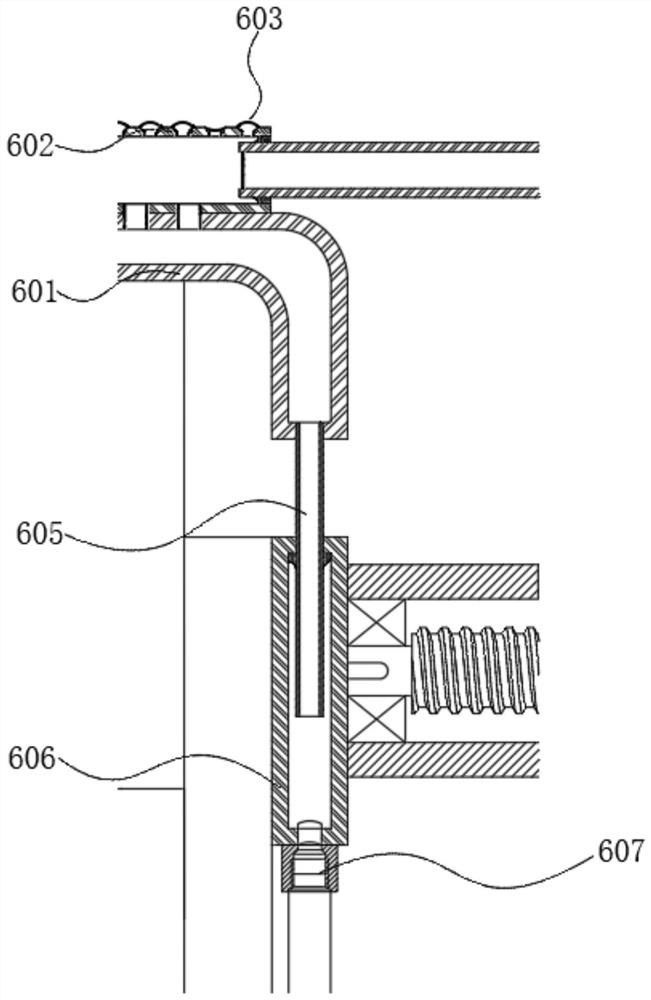

[0034] A driving assembly 3 is installed at the axial center of the lower end surface of the chassis 1 to control the overall movement and steering. An elevator 5 fixed at the axial center of the chassis 1 is arranged above the driving assembly 3. The output end of the elevator 5 A tray assembly 6 is connected;

[0035] The outer wall around the chassis 1 is also fixed with a plurality of distance sensors 8, which can make the handling robot sense the distance of obstacles and avoid them in time, which improves the safety performance. The device 9 can sense the height of the bottom of the shelf in advance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com