Accurate and flexible flour blending process

A flour, flexible technology, used in conveyor objects, transportation and packaging, loading/unloading, etc., can solve problems such as the inability to guarantee the accuracy and long-term stability of flour mixing, reduce customer waiting time, avoid product failure, Guaranteed effect of long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

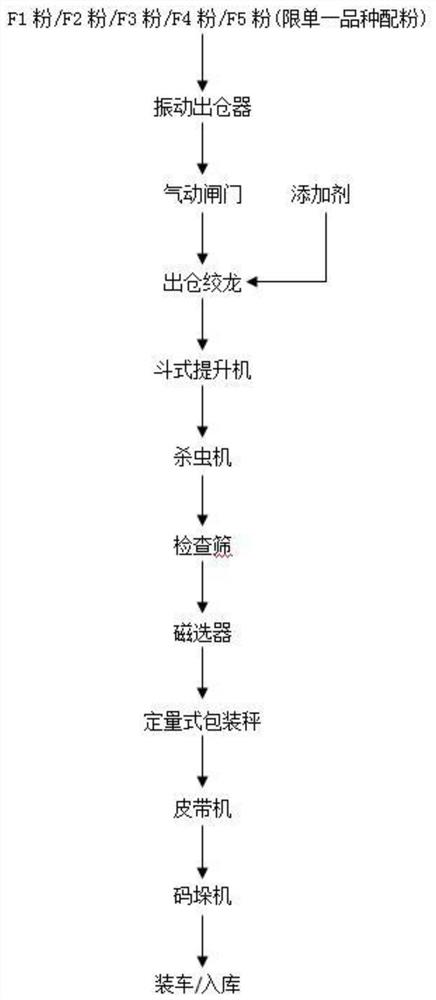

[0033] like figure 1 As shown, the present embodiment is a single powder mixing process.

[0034] A precise and flexible powder blending process for flour, characterized in that it comprises the following steps:

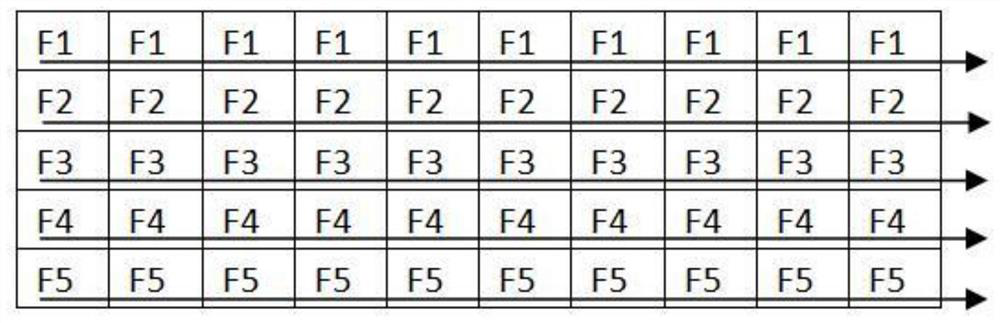

[0035] Step 1. Classify the flour, and then put each type of flour with the classification number into multiple powder bins;

[0036] Step 2. The flour in the powder bin is transported to the bucket elevator through the vibrating outlet device, the pneumatic gate and the outlet auger in turn, and the additive is added to the flour in the outlet auger from the opening on the outlet auger;

[0037] Step 3, the flour in the bucket elevator enters the insecticide machine for insecticidal treatment;

[0038] Step 4. The flour treated by the insecticide machine is processed by an inspection sieve and a magnetic separator, and then arrives at a quantitative packaging scale for weighing and packaging;

[0039] Step 5, the weighed and packaged flour is transported to the p...

Embodiment 2

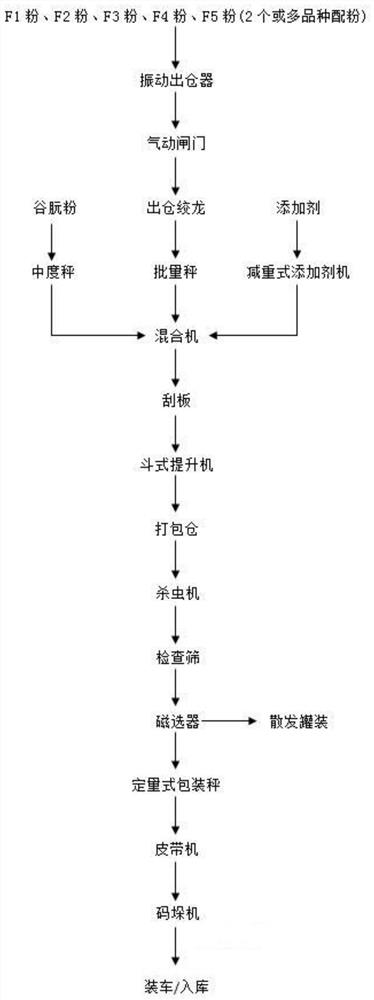

[0042] like figure 2 Shown, the present embodiment is the flow process of mixing powder.

[0043] A precise and flexible powder mixing process for flour, comprising the following steps:

[0044] Step 1. Classify the flour, and then put each type of flour with the classification number into multiple powder bins;

[0045] Step 2. Flour in the powder bin enters into the bin-out auger through the vibrating bin-out device and the pneumatic gate in sequence;

[0046] Step 3, the flour out of the auger is weighed in batches;

[0047] Step 4, enter the mixer through the flour weighed in batches, and then add the gluten powder weighed through the moderate scale and the additive added through the weight loss additive machine into the mixer for mixing;

[0048] Step 5. The flour mixed by the mixer is processed by the scraper and then enters the bucket elevator;

[0049] Step 3. The flour in the bucket elevator enters the insecticide machine for insecticidal treatment. Before the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com