A normal temperature nitriding process and processing device based on laser thermal-mechanical effect

A laser and nitriding technology, applied in metal material coating process, solid-state diffusion coating, coating and other directions, can solve the problems of grain refinement weakening, long nitriding treatment time, affecting strengthening effect, etc. Uniformity, avoid coarse grains, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

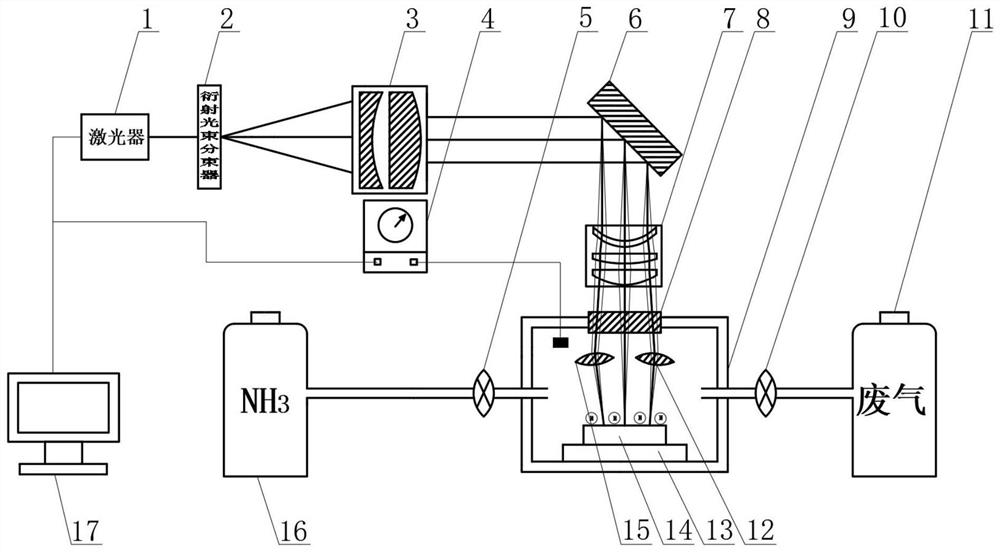

[0026] Such as figure 1 As shown, the processing device of the normal temperature state nitriding process based on the laser thermal-mechanical effect of the present invention includes a laser 1, a sealed box 9, a diffractive beam splitter 2, a combined lens A3, a combined lens B7, and a mirror 6 , the first focusing mirror 12, the second focusing mirror 15 and the ammonia cylinder 16; the workpiece 14 to be nitrided is placed in the sealed box 9, and the bottom of the workpiece 14 to be nitrided is provided with a three-axis linkage workbench 13 for nitriding The workpiece 14 moves three-dimensionally. High-temperature and high-pressure resistant quartz glass 8 is installed on the upper part of the sealing box 9, and the laser beam is irradiated on the workpiece 14 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com