Cloth dyeing equipment for textile processing

A technology for dyeing equipment and fabrics, which is applied to textile processing machine accessories, textile material processing, and textile material drums, etc. It can solve the problems of inability to adjust the size of a single dyeing, lack of adjustment devices in dyeing equipment, and low work efficiency. It is easy to add dyes, improve the dyeing effect, and facilitate maintenance and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

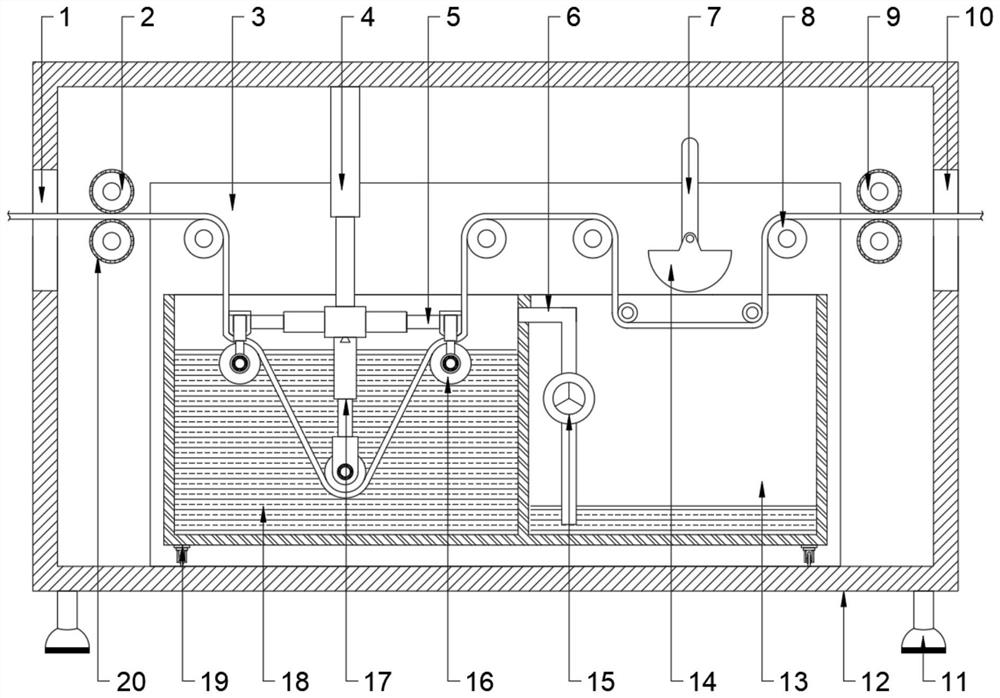

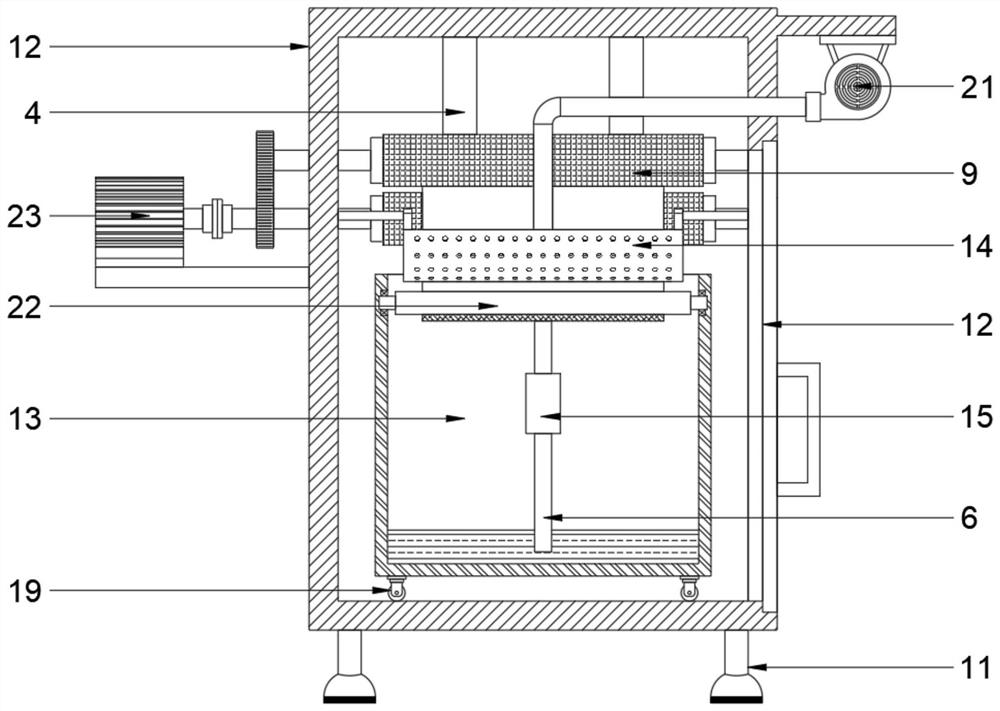

[0025] see Figure 1~4 , in the embodiment of the present invention, a fabric dyeing equipment for textile processing, comprising a box body 12 and a dyeing assembly arranged inside the box body 12, the two sides of the box body 12 are respectively provided with a material inlet 1 and a material outlet 10 And it is also provided with a feeding device inside to facilitate the input and output of fabrics; the dyeing assembly includes a clamping device, a dye box and a blowing device, and the dye box is placed at the bottom of the box body 12 and its interior is divided into dyeing chambers 18 And return chamber 13, described return chamber 13 communicates with dyeing chamber 18 through return pipe 6 and is also provided with return pump 15 on return pipe 6; The upper end of described clamping device is fixedly installed on the box body 12 top and its lower end is positioned at dyeing chamber 18 inside, the blowing device is fixedly installed on the side wall of the box body 12 a...

Embodiment 2

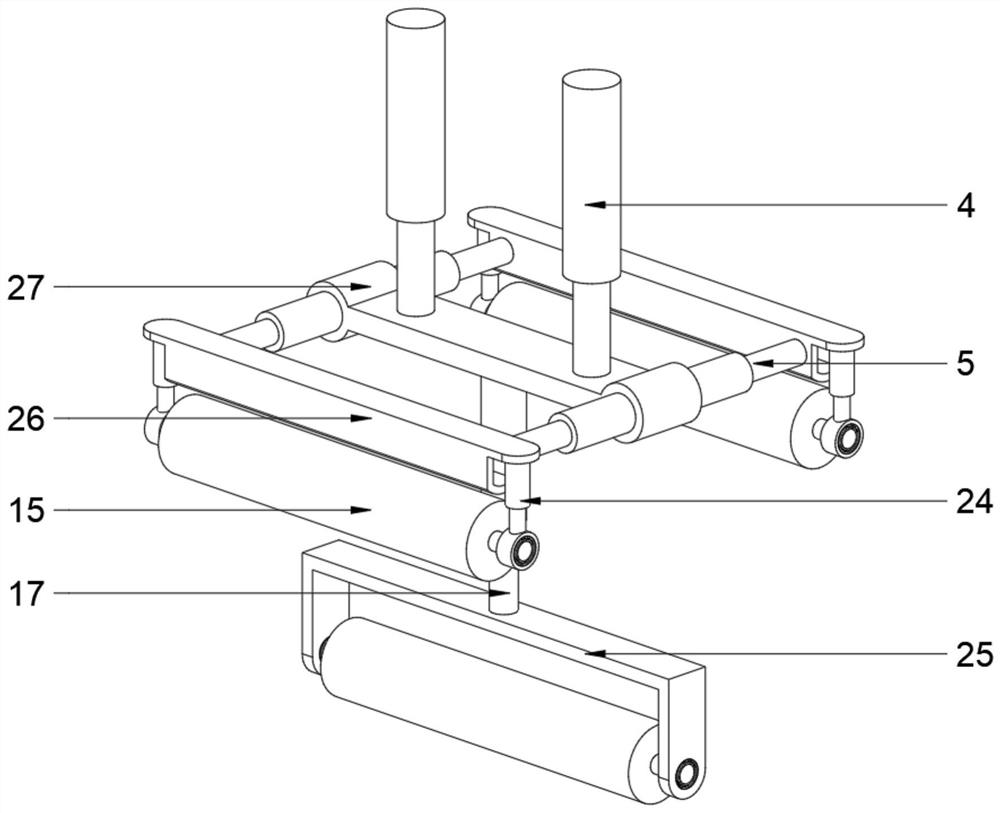

[0034] see Figure 5 , in the embodiment of the present invention, a cloth dyeing equipment for textile processing, in order to ensure the comprehensiveness of cloth dyeing and prevent leakage of dyeing caused by clamping the cloth, on the basis of embodiment 1, the dyeing baffle 26 is close to the dyeing roller One side of 16 is an arc-shaped structure. By cooperating with the dyeing roller 16, the area for clamping the cloth is reduced. The inside of the dyeing baffle 26 is provided with a through hole and the bottom of the through hole is provided with multiple sets of circular holes communicating with the outside world. During the dyeing process, the dye enters the inside of the dyeing baffle 26 from both ends of the through hole and contacts the cloth through the circular hole, so that the clamped part can also be dyed, improving the dyeing effect.

[0035] The working principle of the present invention is:

[0036] When working, fine-tune the length of the supporting le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com