Visual horizontal annulus rock debris migration simulation equipment

A technology for simulating equipment and horizontal rings, applied in teaching models, wellbore/well components, measurements, etc., it can solve the problems of not considering the roughness of the actual annulus well wall, inability to simulate more realistically, and complex structure, so as to ensure experimental results. Reliable, easy to observe, accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

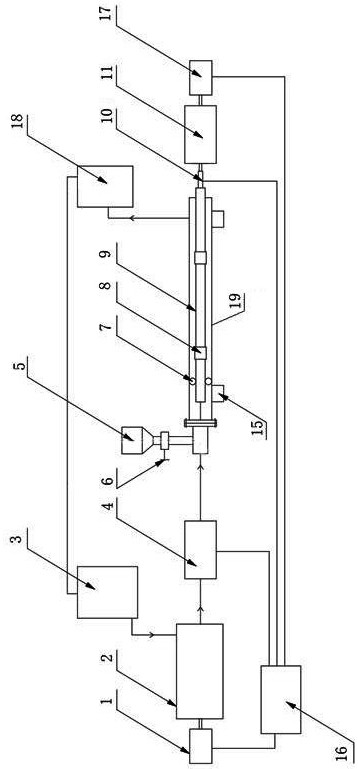

[0027] see figure 1 , a visualized horizontal annular cuttings migration simulation equipment, including a drilling fluid device, and also includes a cuttings feeding device, a simulated wellbore 19 device, a drill pipe 9 rotation eccentric device, a cuttings separator 18 and a computer 16, the drilling The liquid device includes a first frequency converter 1, a drilling fluid pump 2, a liquid storage tank 3 and a liquid flowmeter 4. The first frequency converter 1 is connected to the drilling fluid pump 2, and the drilling fluid pump 2 is connected to the liquid storage tank 3 and the liquid The flowmeter 4 is connected; the cuttings feeding device includes a cuttings tank 5 and a feed control valve 6 installed on the cuttings tank 5; the simulated wellbore 19 device includes a simulated wellbore 19 and a fixed seat 15, and the simulated wellbore 19 is fixed On the fixed seat 15; the drill rod 9 rotation eccentric device comprises an eccentric 7, a drill rod connection sectio...

Embodiment 2

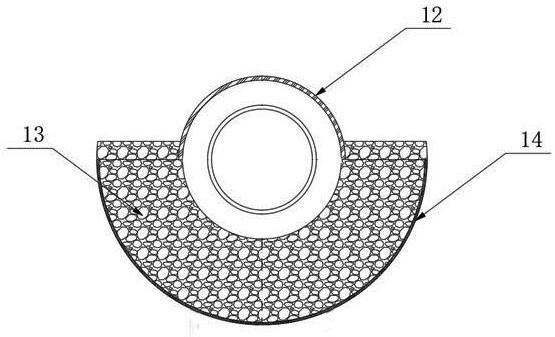

[0030] see figure 1 and figure 2, a visualized horizontal annular cuttings migration simulation equipment, including a drilling fluid device, and also includes a cuttings feeding device, a simulated wellbore 19 device, a drill pipe 9 rotation eccentric device, a cuttings separator 18 and a computer 16, the drilling The liquid device includes a first frequency converter 1, a drilling fluid pump 2, a liquid storage tank 3 and a liquid flowmeter 4. The first frequency converter 1 is connected to the drilling fluid pump 2, and the drilling fluid pump 2 is connected to the liquid storage tank 3 and the liquid The flowmeter 4 is connected; the cuttings feeding device includes a cuttings tank 5 and a feed control valve 6 installed on the cuttings tank 5; the simulated wellbore 19 device includes a simulated wellbore 19 and a fixed seat 15, and the simulated wellbore 19 is fixed On the fixed seat 15; the drill rod 9 rotation eccentric device comprises an eccentric 7, a drill rod con...

Embodiment 3

[0034] see figure 1 and figure 2 , a visualized horizontal annular cuttings migration simulation equipment, including a drilling fluid device, and also includes a cuttings feeding device, a simulated wellbore 19 device, a drill pipe 9 rotation eccentric device, a cuttings separator 18 and a computer 16, the drilling The liquid device includes a first frequency converter 1, a drilling fluid pump 2, a liquid storage tank 3 and a liquid flowmeter 4. The first frequency converter 1 is connected to the drilling fluid pump 2, and the drilling fluid pump 2 is connected to the liquid storage tank 3 and the liquid The flowmeter 4 is connected; the cuttings feeding device includes a cuttings tank 5 and a feed control valve 6 installed on the cuttings tank 5; the simulated wellbore 19 device includes a simulated wellbore 19 and a fixed seat 15, and the simulated wellbore 19 is fixed On the fixed seat 15; the drill rod 9 rotation eccentric device comprises an eccentric 7, a drill rod co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com