Drying equipment for bioengineering based on environmental protection

A bioengineering and drying equipment technology, applied in the direction of drying solid materials, dry goods handling, drying chamber/container, etc., can solve the problems of incomplete drying of items, low work efficiency, slow drying speed, etc., to save manpower and improve work The effect of quality, convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

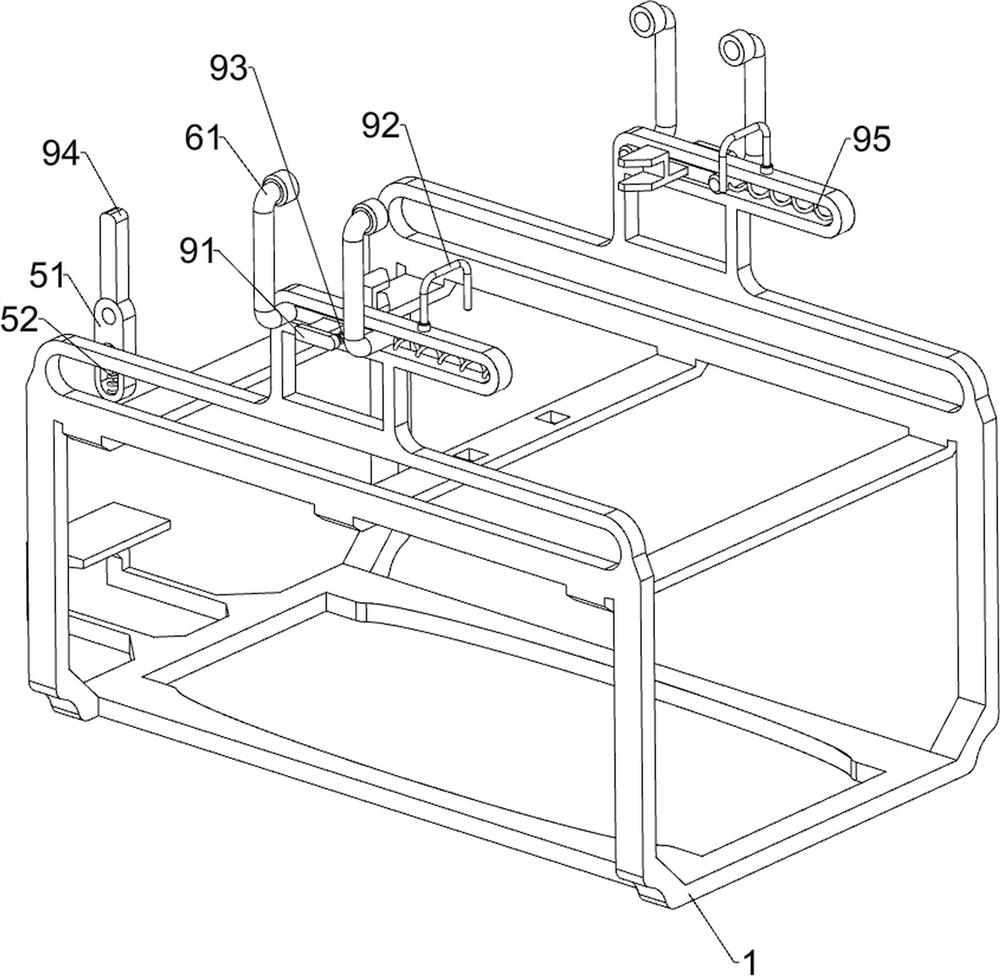

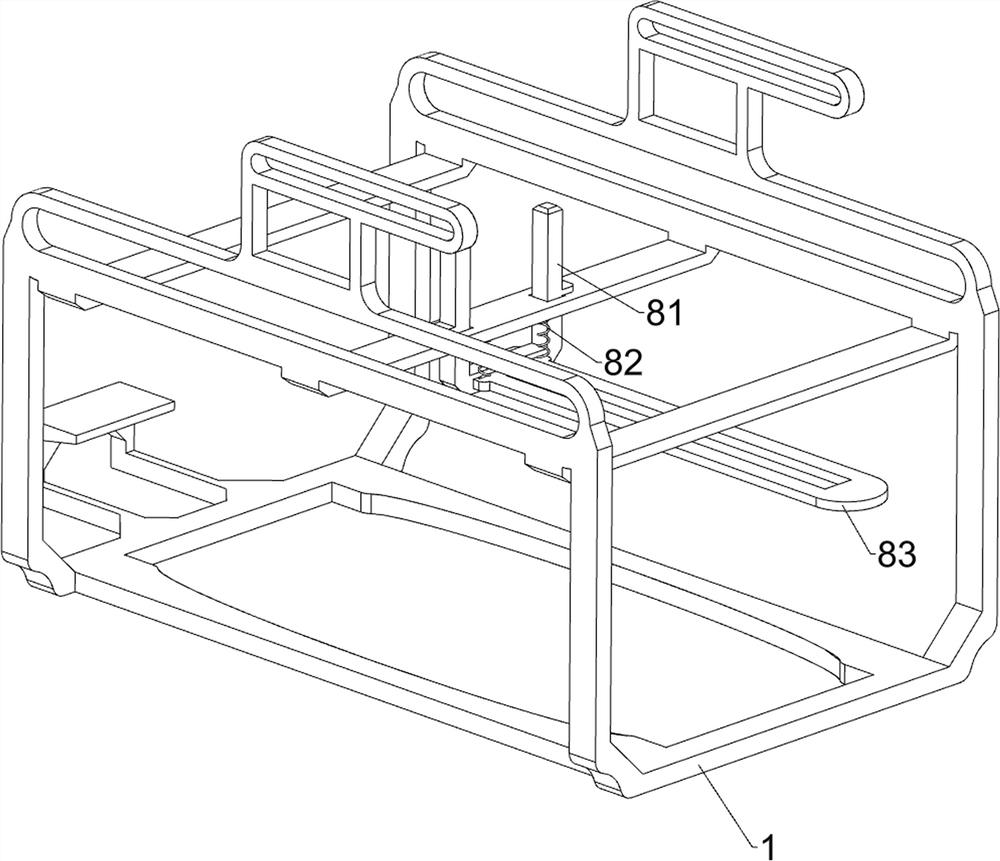

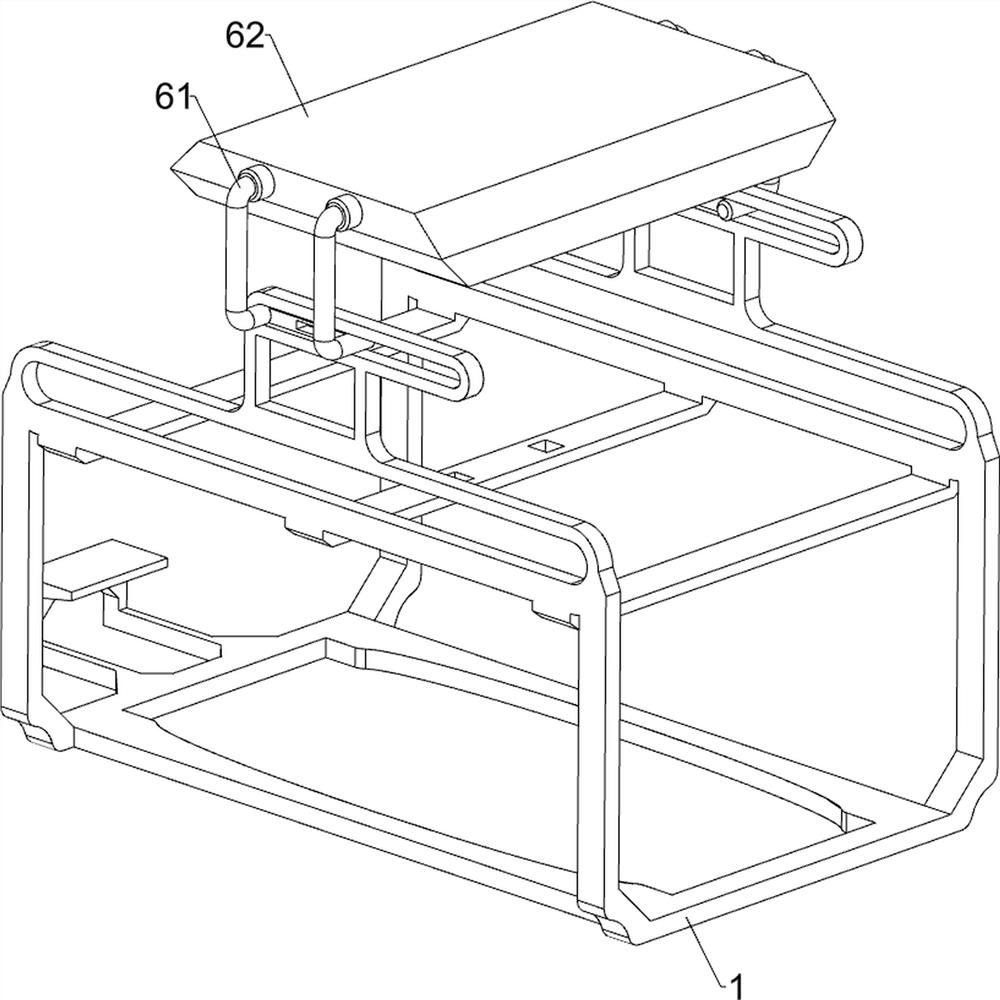

[0026] A kind of drying equipment for bioengineering based on environmental protection, such as figure 1 As shown, it includes a frame 1, a circular shaft 2, a connecting rod 3, a drive assembly 4, a placement assembly 5 and a drying assembly 6. The circular shaft 2 is slidingly provided on the frame 1, and the bottom of the circular shaft 2 is equipped with a connecting rod. 3. The frame 1 is provided with a driving assembly 4 driven by rotation, the frame 1 is provided with a placement assembly 5, and the frame 1 is provided with a drying assembly 6 for drying by sliding.

[0027] When using the device, first place the items to be dried through the placement component 5, then push the placement component 5 to move to the right through the drive component 4, and at the same time dry the items through the drying component 6. After completion, place the dried items Take it out, then control the drive assembly 4 to drive the placement assembly 5 to reset, and close the drive ass...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a pouring assembly 7, and the pouring assembly 7 includes a rack 71 and a full gear 72. The front and rear two parts on the right side of the frame 1 are provided with a rack 71, and the front and rear sides of the placement frame 53 are provided with full gears. The gear 72, the rack 71 meshes with the full gear 72.

[0036] When the article is dried, the placement frame 53 drives the full gear 72 to move to the right, and when the full gear 72 moves to the right to mesh with the rack 71, the full gear 72 rotates to drive the placement frame 53 to rotate downwards to pour the article out, completing Finally, the placement frame 53 drives the full gear 72 to move to the left and reset, and at the same time, under the action of the rack 71, the full gear 72 moves to the left and resets to drive the placement frame 53 to rotate upwards to reset, so that the article can be poured out auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com