Online fault detection system and method for rotating diode of AP1000 rod power supply unit

A technology of rotating diodes and power supply units, which is applied in the direction of diode testing, continuity testing, and single semiconductor device testing, etc. It can solve the problem of lack of timeliness, different effects of excitation current and terminal voltage, and failure to detect rotating diodes of AP1000 rod power supply units. Faults and other problems, to improve the efficiency and convenience of fault detection, improve operational stability, and ensure the reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

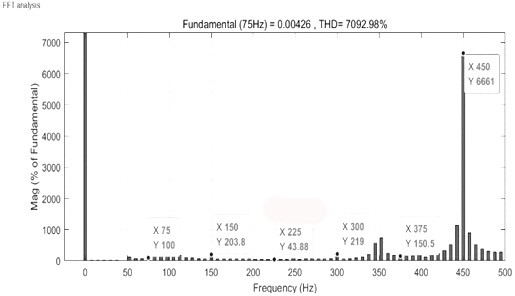

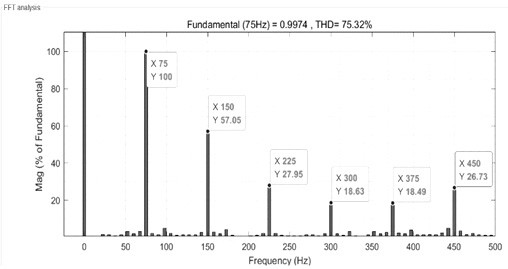

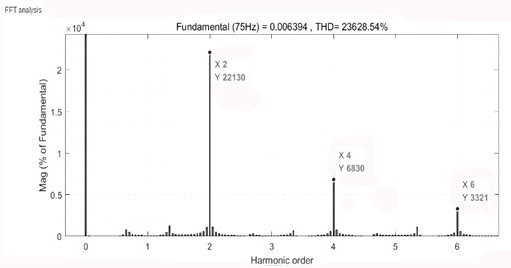

[0042] An online fault detection system for rotating diodes of AP1000 bar power unit, including excitation current acquisition equipment, excitation current analysis platform and harmonic content fault comparison module.

[0043] The excitation current acquisition equipment is used to collect the excitation current of the AP1000 rod power unit, and the excitation current analysis platform is used to obtain the harmonic content of the collected excitation current. The harmonic content fault comparison module includes a harmonic content fault comparison table for judging whether there is a fault in the rotating diode of the AP1000 rod power unit based on the obtained harmonic content and the specific fault type. The application system can detect whether there is a fault in the rotating diode on-line d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com