High-power and high-uniformity miniature ultraviolet LED illuminator

A technology of LED illuminator and uniformity, which is applied in the direction of instruments, micro-lithography exposure equipment, photoplate making process of pattern surface, etc., can solve the problem of high light loss energy, low light output energy, and uneven light output energy Improve the output uniformity of the system, increase the output energy of the system, improve the speed and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

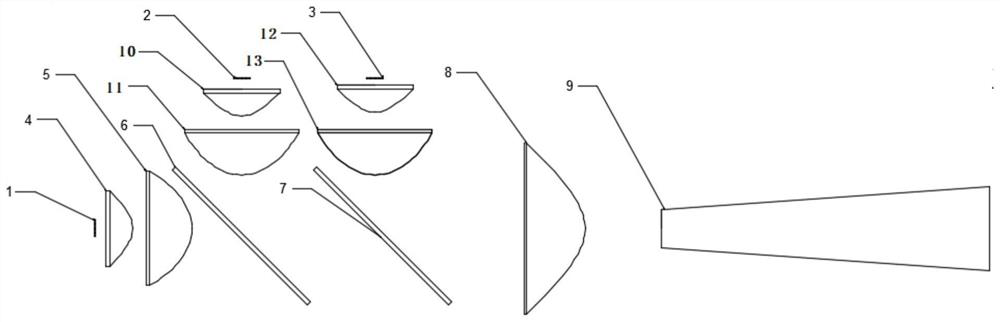

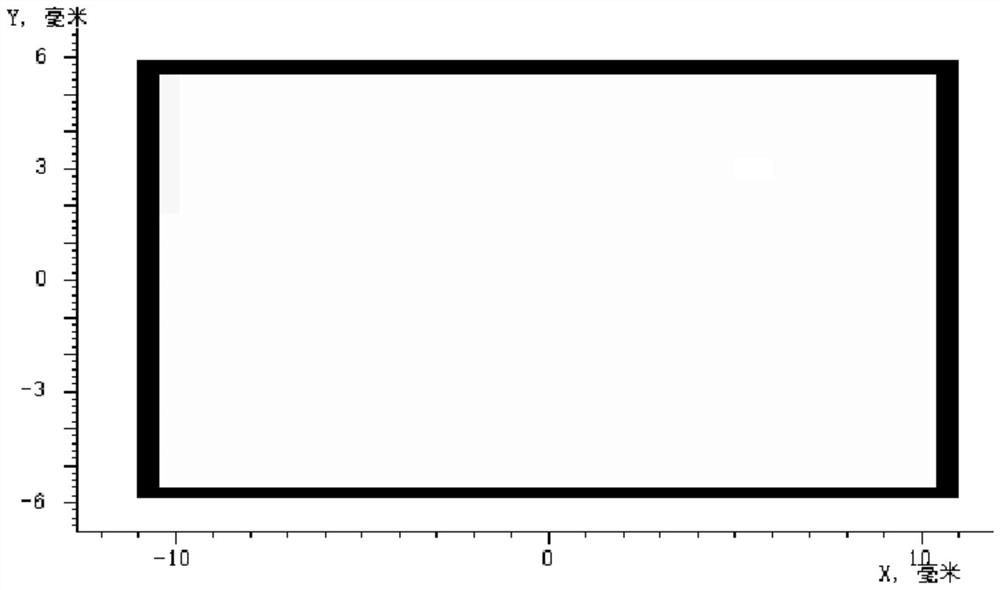

[0025] see Figure 1-2 , the present invention provides a technical solution: a high-power, high-uniformity miniature ultraviolet LED illuminator, including a first LED lamp bead 1, a second LED lamp bead 2, a third LED lamp bead 3, a first collimating lens combination, the second collimating lens combination, the third collimating lens combination, the first light combining lens 6, the second light combining lens 7, the focusing lens 8 and the square rod 9, the second collimating lens combination is located in the first collimating lens On the right side above the collimating lens combination, the third collimating lens combination is located on the right side of the second collimating lens combination, and the first collimating lens combination includes the first small collimating lens 4 and the first large collimating lens 5, The first small collimating lens 4 is located on the left side of the first large collimating lens 5, the first small collimating lens 4 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com