High-tensile thick steel plate for extremely low temperature and manufacturing method thereof

A manufacturing method and high-tension technology, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low temperature toughness reduction, austenite instability, expensive Ni alloying elements, etc., and achieve excellent cold workability and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

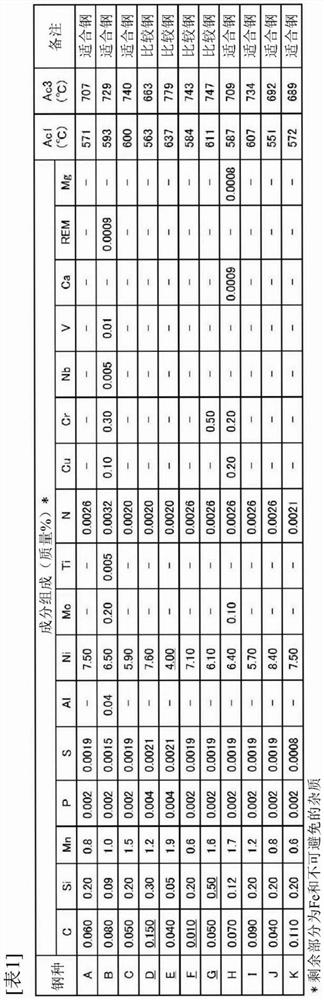

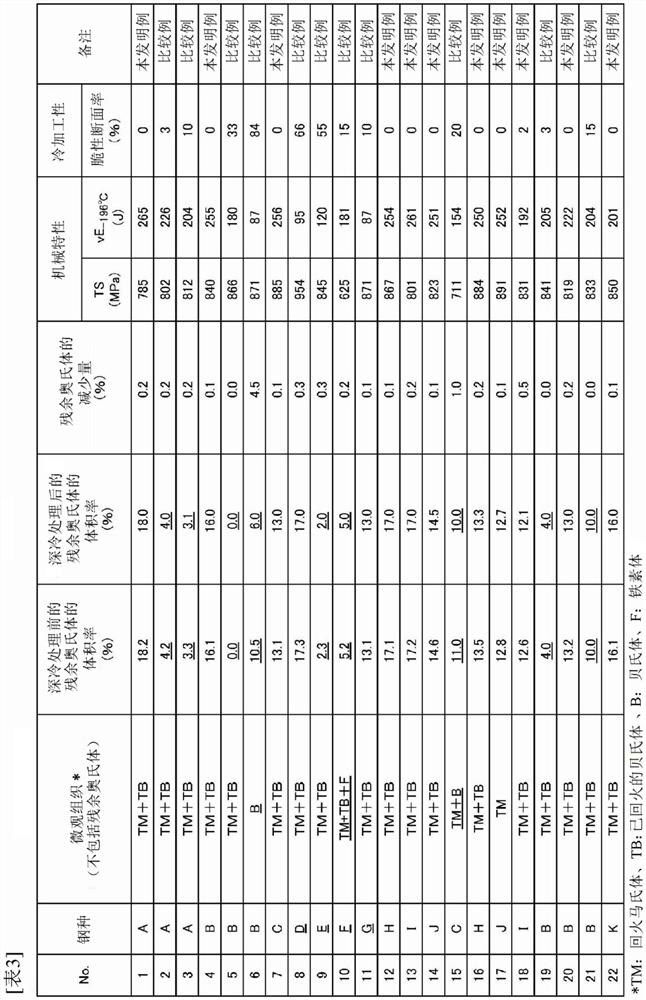

[0156] A high-tensile high-tensile steel plate for extremely low-temperature use was manufactured in accordance with the procedure described below, and properties of the obtained high-tensile-strength steel plate for extremely low-temperature use were evaluated.

[0157] First, molten steel having the composition shown in Table 1 was melted in a converter, and a billet (thickness: 250 mm) was produced as a billet material by a continuous casting method. In addition, the Ac1 point (°C) obtained by the above formula (1) and the Ac3 point (°C) obtained by the formula (2) are shown in Table 1 together.

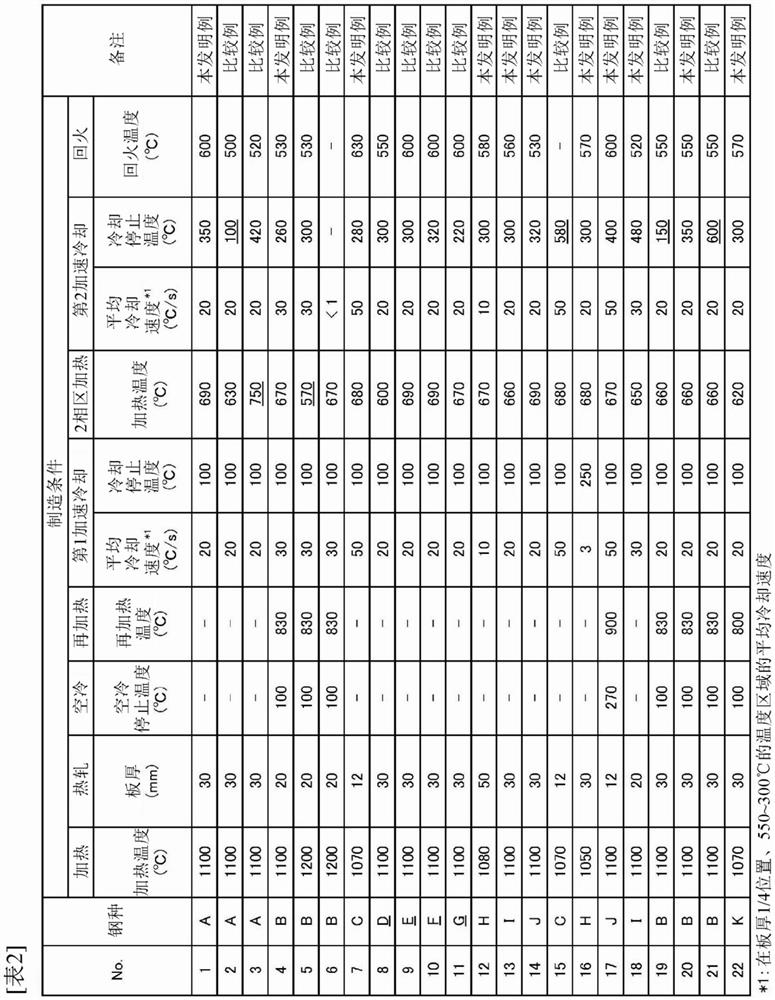

[0158] Next, the obtained slabs were heated to the heating temperatures shown in Table 2, and hot-rolled to obtain hot-rolled steel sheets with the thicknesses shown in Table 2. Next, first accelerated cooling is performed on the hot-rolled steel sheet. Table 2 shows the average cooling rate and cooling stop temperature of the above-mentioned first accelerated cooling. In additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com