A kind of edge trimming equipment for blown film

A blown film and blown film technology, applied in the field of machinery, can solve the problems of increased wrinkle surface, decreased blow molding quality, affecting the integrity and tightness of blow molding surface, etc., so as to improve the tightness of end corner wrapping and ensure smoothness. The effect of improving the degree and uniformity of the film protection effect

Active Publication Date: 2022-05-31

临沂天勤塑业有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the deficiencies in the prior art, the object of the present invention is to provide a blown film edge trimming equipment to solve the problem of the blown film's edge trimming and corner sealing material packaging, which will cause the blown quality to decline due to the soft texture and high elongation of the film. , and the wrinkled surface increases after the film is cut, which interferes with the subsequent overall equipment transportation and continuous film supply and efficiency, resulting in aggravated tensile damage on the subsequent product film surface, affecting the integrity and tightness of the blowing surface, and affecting the mechanical blowing. The efficiency of plastic film trimming and packaging is reduced, which affects the unqualified rate of film cutting of batch products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

[0042] Through the front end angle pulling and trimming the back edge sliding pressure sealing film, the subsequent blow molding operation is framed and prevented from tripping,

[0043] The present invention, through the mutual combination of the above-mentioned components, achieves that the use of the encapsulation horizontal groove 2 is matched with the blown film cutting door frame 4,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

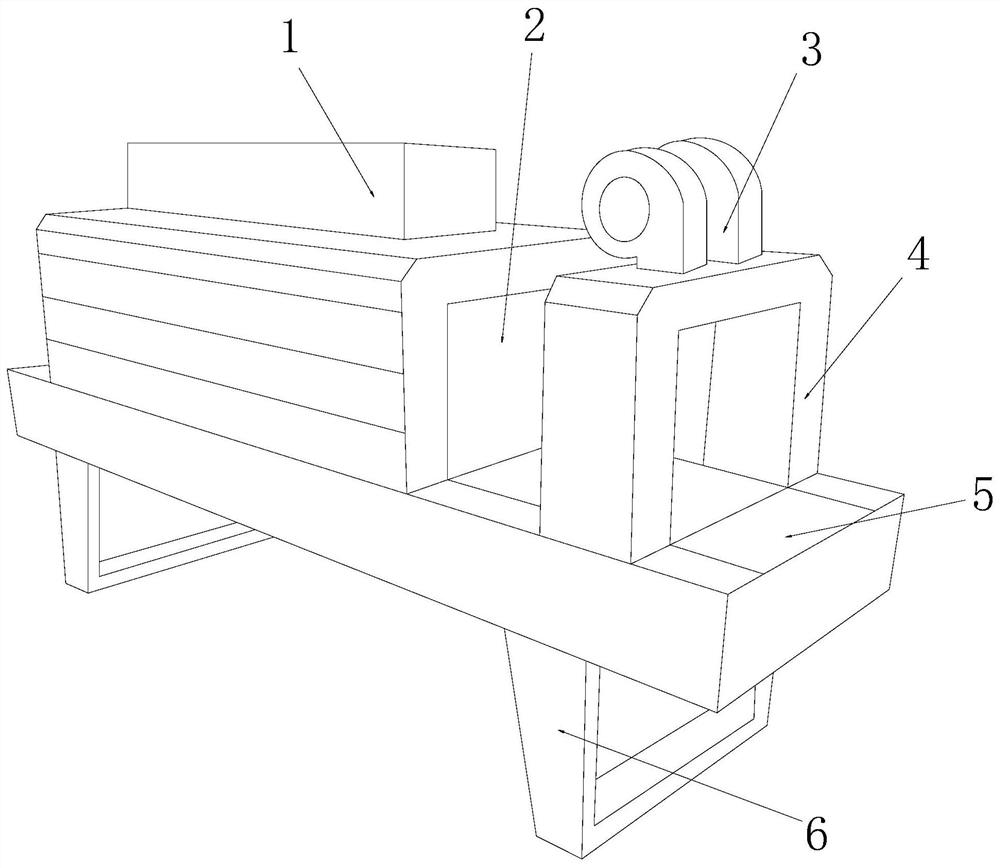

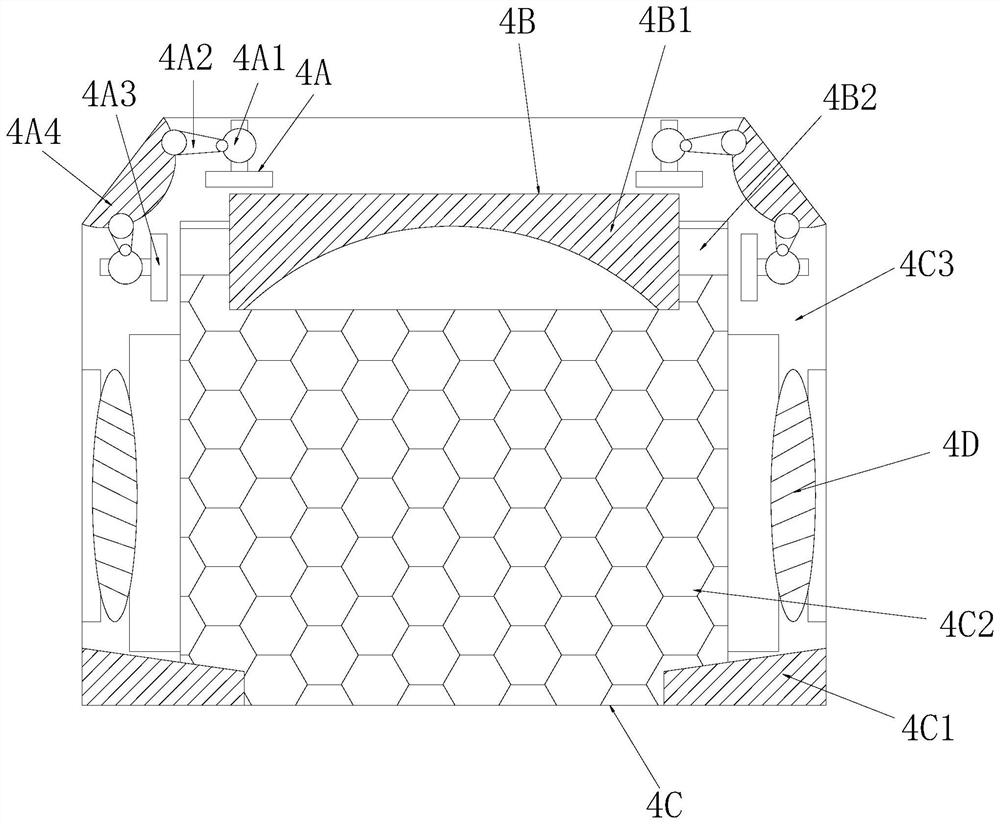

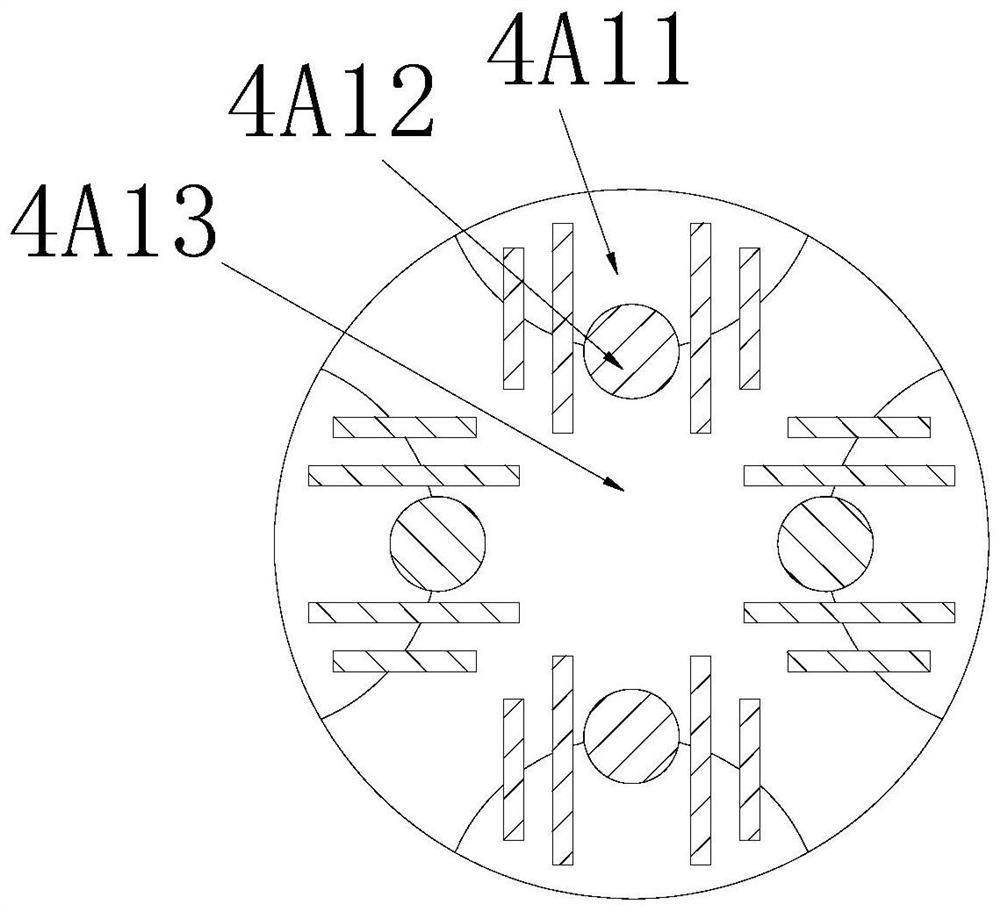

The invention discloses a blown film edge trimming device, the structure of which comprises: an electric control box, a packaging horizontal tank, a blower, a blown film cutting door frame, a conveyor belt table, a bracket frame tripod, and the invention realizes the use of the packaging horizontal tank and The blown film is matched with the door frame, and the right side of the grid door frame and the alignment clip seat is blown and packaged by encapsulating the horizontal groove to form a smooth adjustment of the operation effect through a short distance of the trimming pressing frame, so that the edge strip density after edge trimming is effective Adjust the flatness by sliding and pressing the column plate and adjust the toughness of sliding and pressing and attaching tight pull to improve the integrity of the air-absorbing mechanical package after the blown centered film bulges, and the smooth anti-wrinkle adjustment of the film end surface The sliding pressure operation is formed by the sliding pressure guillotine, so that the air bubbles wrapped in the film are pressed out to ensure the smoothness and uniformity of the product after filming.

Description

A blown film trimming equipment technical field [0001] The present invention is a blown film trimming equipment, belonging to the field of machinery. Background technique The frame groove drawing processing and encapsulation of the blown film is efficient, and the storage products in the follow-up equipment are connected with film trimming and corner sealing. angle, so as to improve the compactness and anti-oxidative sealing efficiency of the film blow-molded attached product, and improve the mechanical processing complete operation of the equipment. The shortcomings of the current technology to be optimized are as follows: [0003] The trimming and corner sealing material packaging of the blown film will cause the blow molding quality to decline because the film is soft in texture and high in ductility. And after the film is cut, the wrinkled surface increases, which interferes with the subsequent overall equipment transportation and continuous film supply and efficie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B61/00B65B61/06

CPCB65B61/00B65B61/06Y02P70/50

Inventor 林怣河

Owner 临沂天勤塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com