Control method for drying down jackets

A control method and technology for down jackets, which are applied in household dryers, textiles, papermaking, and washing devices, can solve the problems of easily damaged down jackets, unsuitable down jackets, and reduced service life of down jackets, so as to avoid damage to down jackets and improve the performance of down jackets. Drying uniformity, the effect of improving drying efficiency and drying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

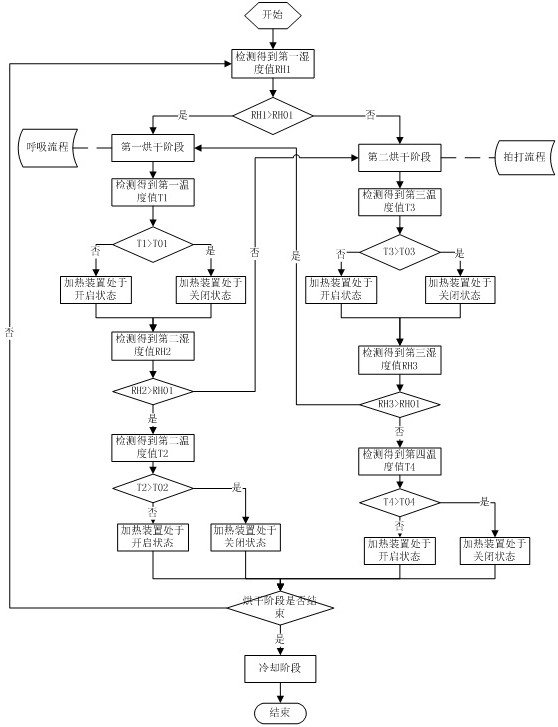

[0057] see figure 1 , is the first embodiment of the control method for drying down jackets proposed by the present invention, a control method for drying down jackets, which has a drying cylinder, a heating component, a component for detecting temperature, and a component for detecting humidity. After the start signal of the down jacket drying mode, the washing machine is controlled to perform the drying program in the following order.

[0058] S10. The first humidity detection and judgment step is to detect the first humidity value RH1, and judge whether the first humidity value RH1 is greater than the first reference humidity RH01, if so, enter the first drying stage, otherwise enter the second drying stage .

[0059] According to the different humidity, it enters different drying stages, the high humidity enters the first drying stage, and the low humidity enters the second drying stage. For the detection of humidity, a humidity sensor or other humidity detection compone...

Embodiment 2

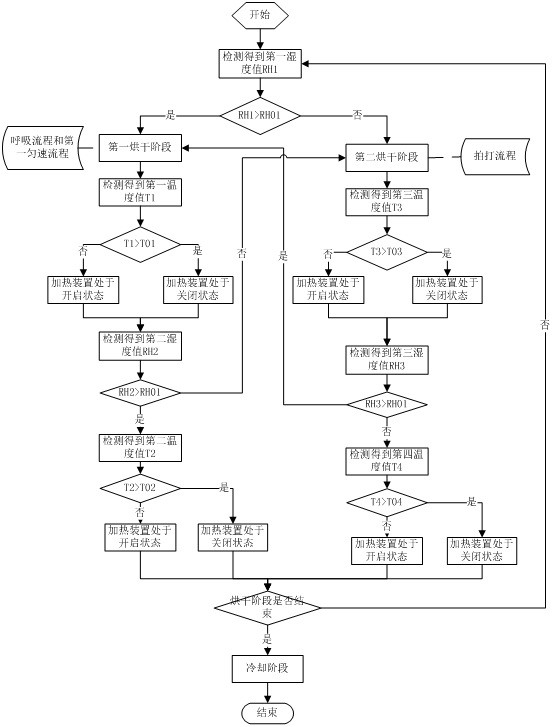

[0080] see figure 2 , the second embodiment is on the basis of the first embodiment, adding the rotation process of the drying drum in the first drying stage; the main difference between the second embodiment and the first embodiment is that: in the first The rotating process of the drying drum used in the drying stage is different, and the first constant speed process is added, and the others can be the same as the first embodiment.

[0081]In the first drying stage, the rotation of the drying cylinder also includes a first constant speed process, the first constant speed process is that the drying cylinder rotates at intervals of the first rotational speed V1, that is, the rotational speed and the stop time are constant values. The first constant speed process and the breathing process are alternately performed, and the running time of the first constant speed process is the same as that of the breathing process; the first speed is 35 rpm / min to 55 rpm / min, and the preferre...

Embodiment 3

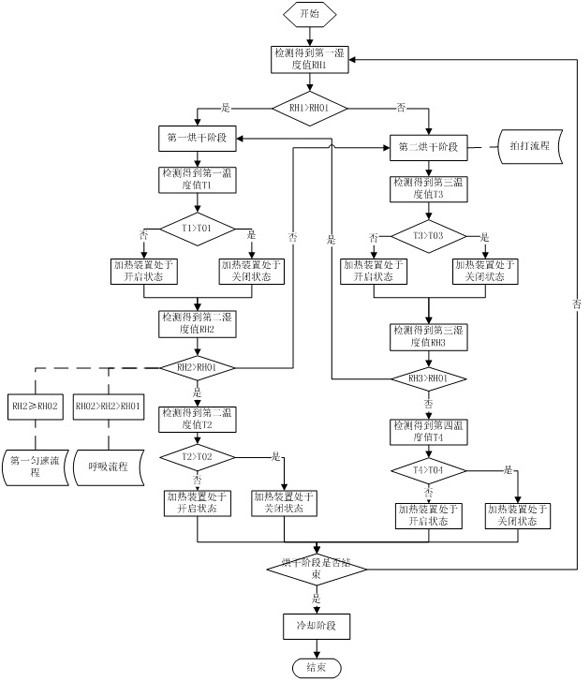

[0083] see image 3 , the third embodiment is on the basis of the first embodiment, adding the rotating process of the drying cylinder in the first drying stage; the main difference between the third embodiment and the first embodiment is: the drying The rotation process of the drying cylinder is different. In the first drying stage, the rotation process adopted by the drying cylinder is controlled according to the humidity, and the other can be the same as the first embodiment.

[0084] In the first drying stage, when the second humidity value RH2 is greater than or equal to the second reference humidity RH02, the rotation of the drying cylinder adopts the first constant speed process; when the second humidity value RH2 is less than the second reference humidity RH02, the drying The rotation of the dry cylinder includes at least a breathing process; the second reference humidity RH02 is greater than the first reference humidity RH01. Of course, at this time the second humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com