Raw material multi-stage grading screening device for starch glue processing

A technology of grading screening and starch glue, which is applied in the direction of separating solids from solids by air flow, sieving, solids separation, etc. Sexual damage, improve work efficiency, prevent offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

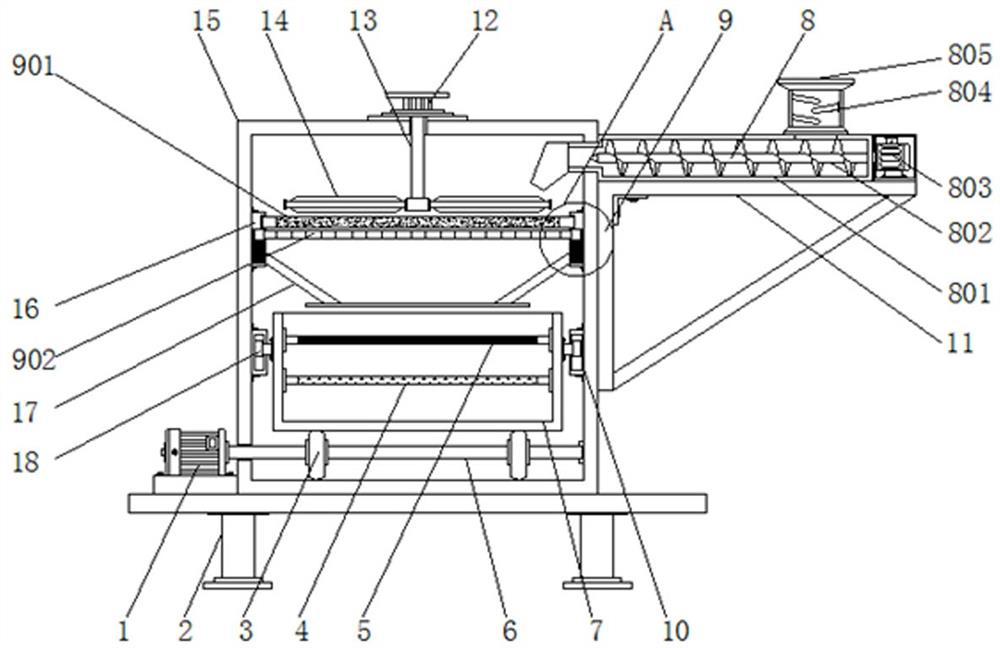

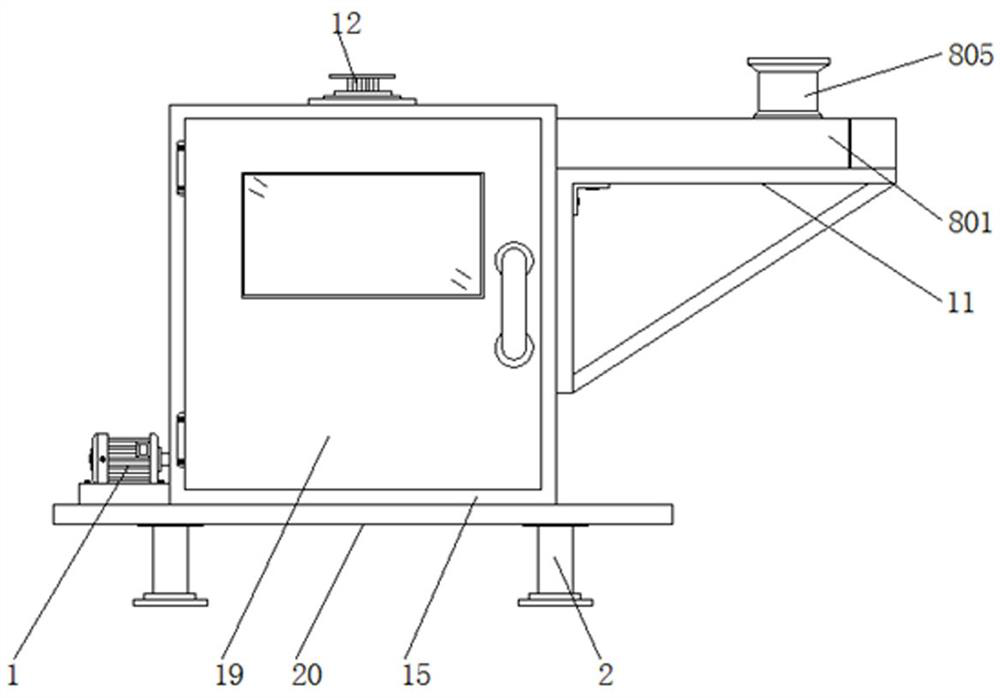

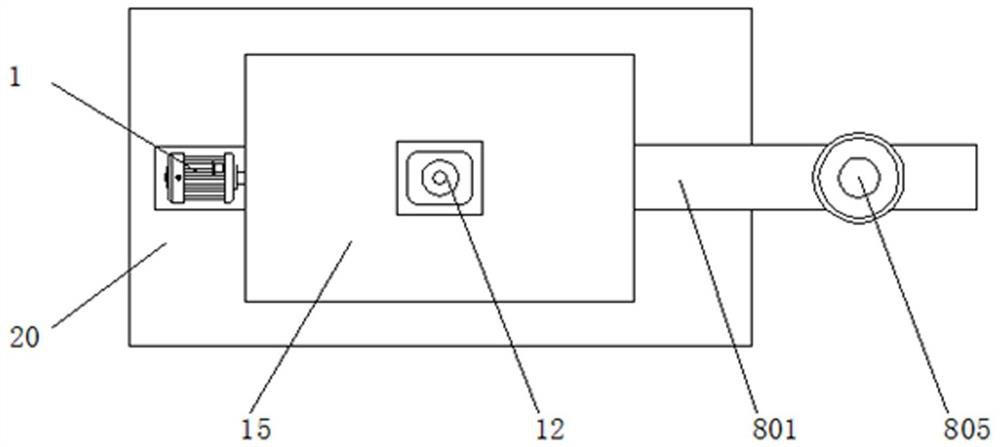

[0027] Example 1: See Figure 1-4 , a raw material multi-stage grading and screening device for starch glue processing, comprising a box body 15, a feeding structure 8 for preventing device clogging, a protective structure 9 with strong protection, and a screening structure with high working efficiency;

[0028] A third driving motor 12 is installed at the middle position of the top of the box body 15. The model of the third driving motor 12 can be 86BL, and the bottom end of the third driving motor 12 is equipped with a main rod 13, and the bottom end of the main rod 13 extends To the inside of the box body 15, and the bottom ends of both sides of the box body 15 are equipped with levers 14, one side of the box body 15 is equipped with a bracket 11, and the feeding structure 8 is arranged on the top of the bracket 11;

[0029] The inner wall of the box body 15 below the driving lever 14 is provided with a second fixed plate 16, and the protective structure 9 is arranged on th...

Embodiment 2

[0034] Embodiment 2: The feeding structure 8 includes a casing 801, a feeding rod 802, a second drive motor 803, a spoiler 804 and a feeding port 805, the casing 801 is arranged on the top of the support 11, and one side of the casing 801 extends to the box body 15, a second drive motor 803 is installed on one side of the shell 801, the model of the second drive motor 803 can be 86BL, and the shell 801 on the side of the second drive motor 803 is provided with a feeding rod 802;

[0035] A feed inlet 805 is installed on the top of the housing 801, and both sides of the feed inlet 805 are uniformly provided with spoilers 804;

[0036] Specifically, such as figure 1 , figure 2 with image 3 As shown, when using this mechanism, the second drive motor 803 is turned on to make the feed rod 802 rotate, and the raw material enters the feed port 805. Under the action of each spoiler 804, the descending speed of the raw material can be slowed down. When the raw material enters Afte...

Embodiment 3

[0037]Embodiment 3: protective structure 9 comprises primary filter screen 901, hole plate 902, first slide block 903 and buffer spring 904, and preliminary filter screen 901 is arranged between the both sides inner walls of the second fixed plate 16, and preliminary filter screen 901 Both sides of the second fixed plate 16 below are provided with first sliders 903, the bottom ends of the first sliders 903 are provided with buffer springs 904, and the bottom ends of the buffer springs 904 are connected to the inside of the second fixed plate 16 The bottom end, the orifice 902 is arranged below the preliminary filter screen 901 between the inner walls on both sides of the second fixed plate 16;

[0038] One side inside the second fixed plate 16 is connected to the orifice plate 902 through the first slider 903, and the orifice plate 902 forms a sliding structure with the second fixed plate 16 through the first slider 903;

[0039] Specifically, such as figure 1 and Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com