Automatic assembling device for atomizing chip of nozzle of soft aerosol atomizer

An automatic assembly and atomizer technology, applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems that it is difficult to obtain the atomization process of fine particles, cannot meet the functional requirements, and cannot be accurately identified. Compact, ensure accuracy, smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

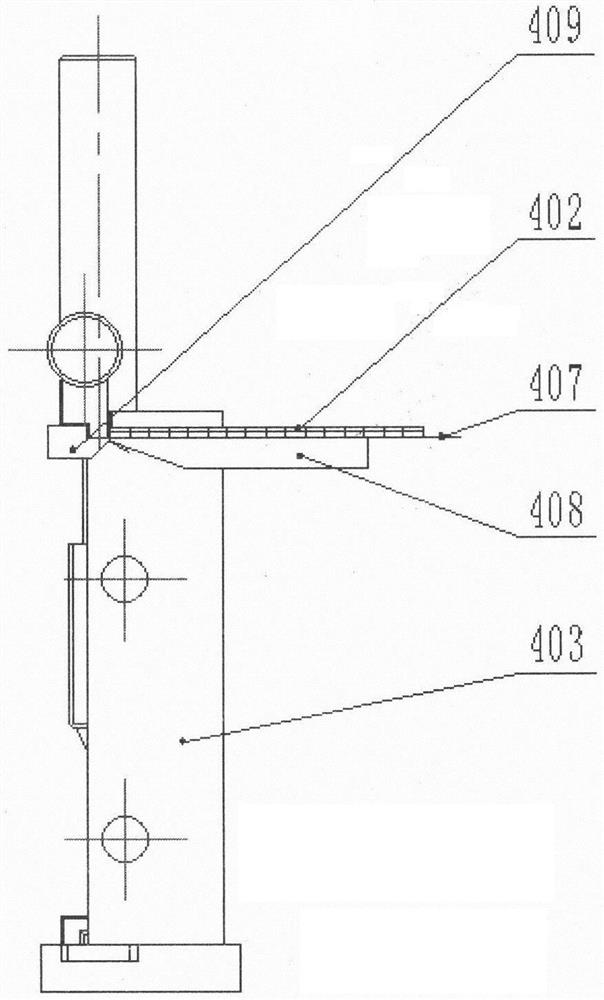

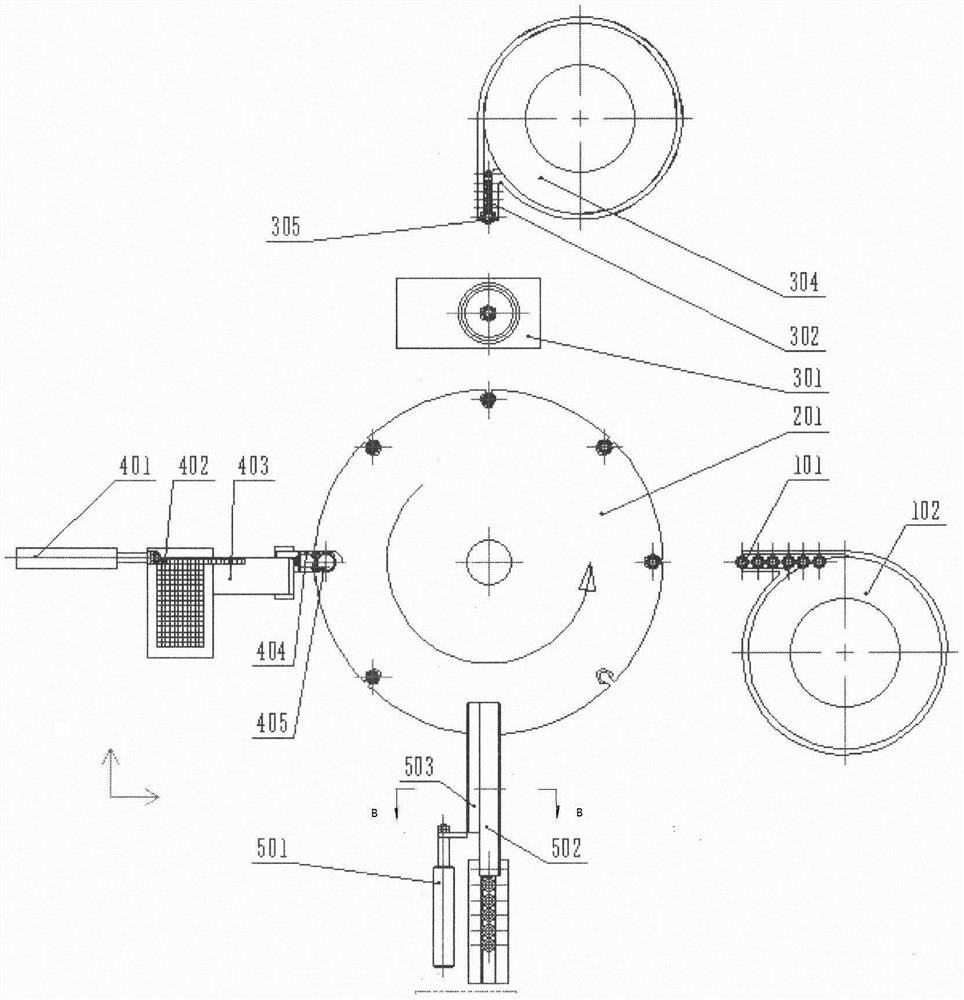

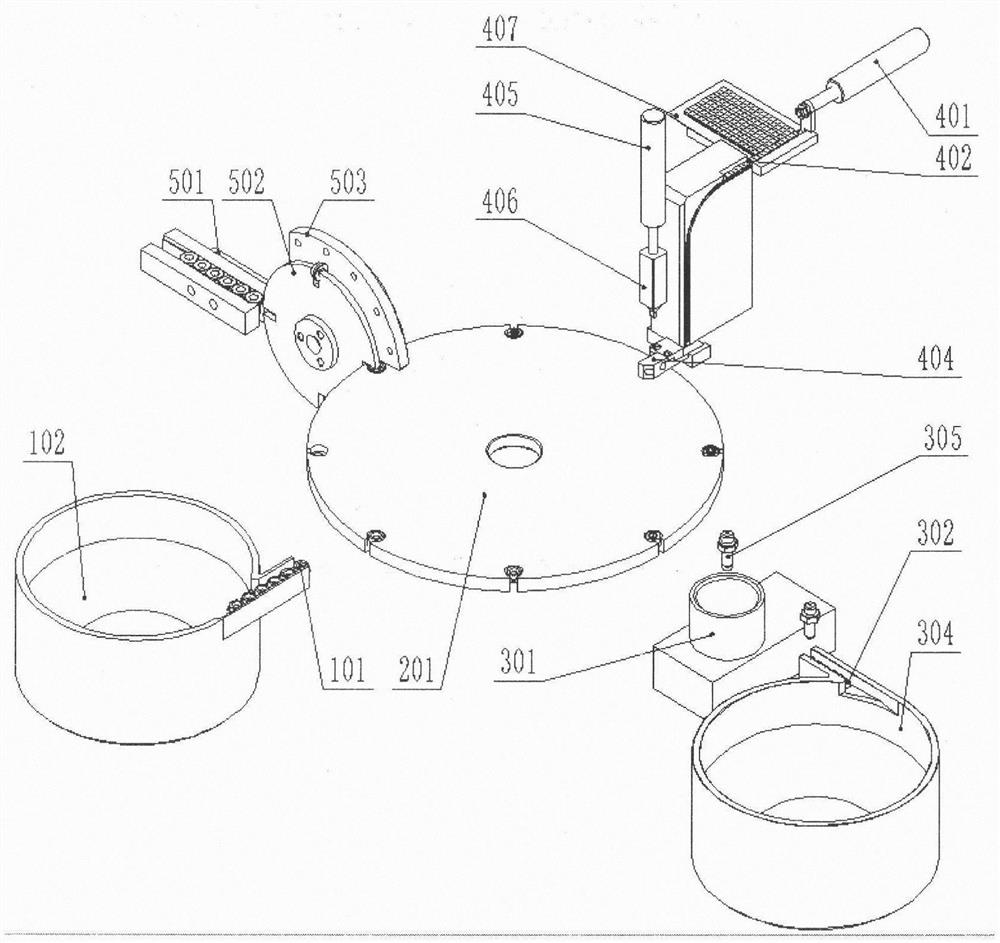

[0025] The present invention is an automatic assembly device for an atomization chip of a soft aerosol nebulizer, such as figure 1 As shown, it includes a stainless steel shell 101, a shell oscillating plate 102, a station equalization turntable 201, an industrial camera 301, a chip holder 302, a support oscillating plate 304, a suction nozzle fixture 305, a horizontal push mechanism 401, an atomizing chip 402, and a guide Block 403, chip clamp 404, pressing mechanism 405, pressing block 406, film 407, middle supporting plate 408, small supporting plate 409, limit block 411, clamping block 412, spring 413, transfer mechanism 501, disc retrieving Plate 502 , transfer bracket 503 , and semicircular guide groove plate 506 .

[0026] Such as figure 1 As shown, the station equalization turntable 201 is provided with positioning fixtures matching the stainless steel shell 101, and the station equalization turntable 201 is driven pneumatically or electrically.

[0027] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com