Automatic control method for temperature and pressure of hot air seam sealing machine

An automatic control and sealing machine technology, applied to sewing tools, household components, household appliances, etc., can solve the problem that the processing temperature or pressure of the hot air seam sealing machine is difficult to match the product processing conditions, and it is difficult to monitor and find the temperature or Problems such as pressure changes, temperature and pressure amplitude fluctuations are difficult to be found, so as to improve processing quality, facilitate experience summarization, and facilitate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solutions and advantages of this application clearer, the following in conjunction with the attached Figure 1-4 And embodiment, this application is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

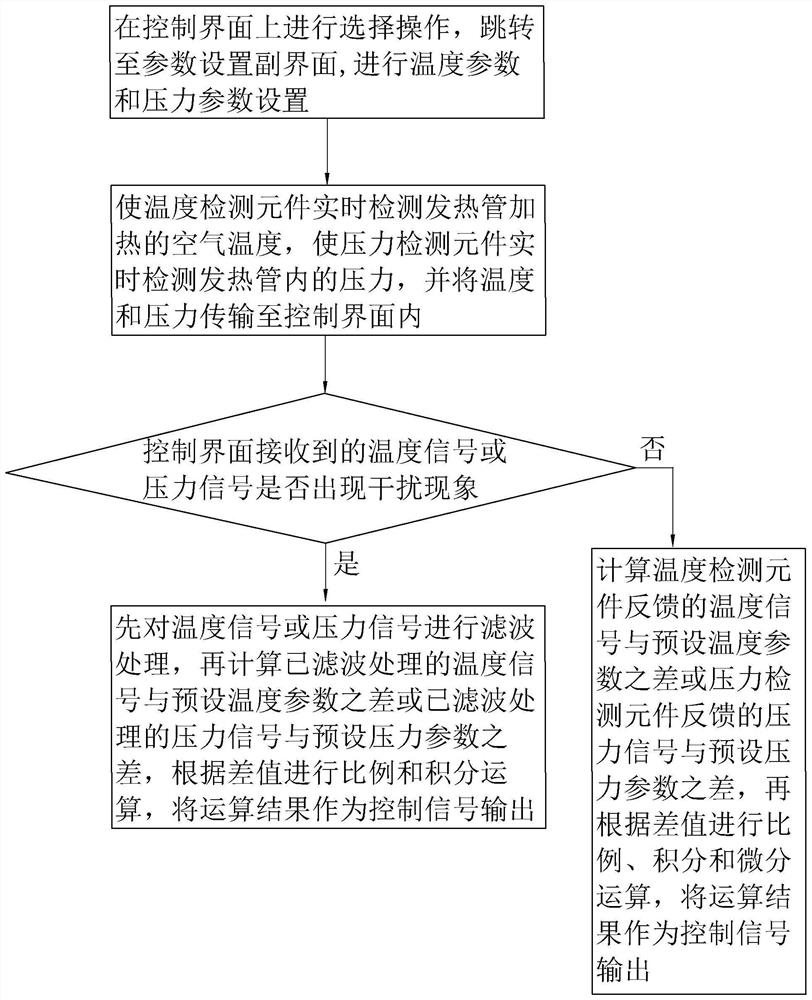

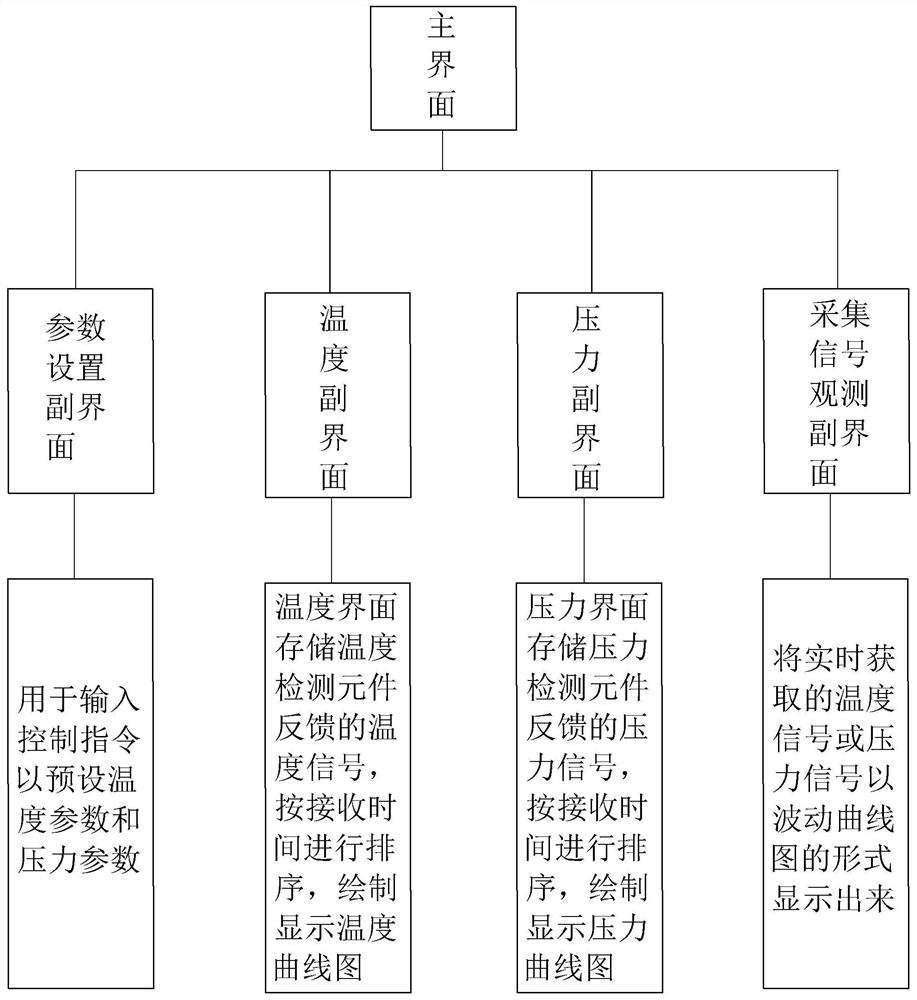

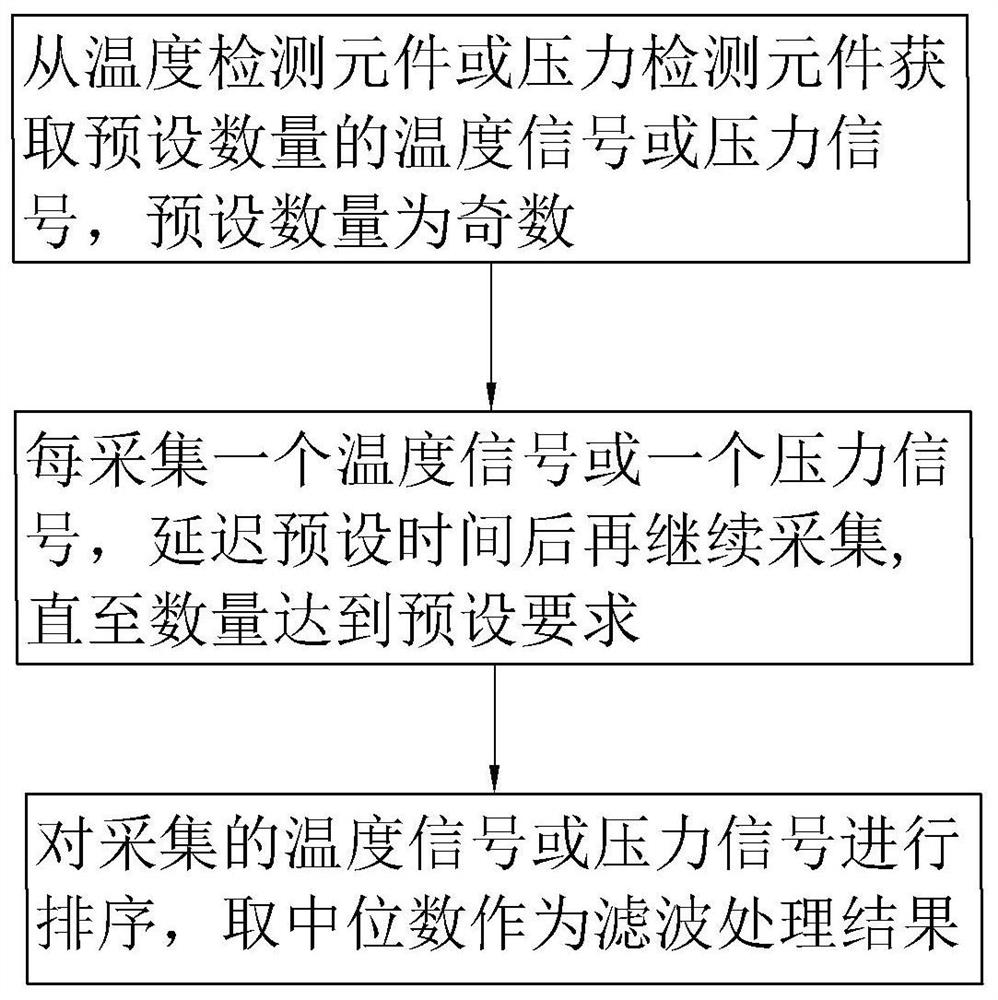

[0042] The embodiment of the present application discloses an automatic control method for temperature and pressure of a hot air seam sealing machine. refer to figure 1 , the automatic control method of temperature and pressure includes preset temperature parameters and pressure parameters in the control interface; make the temperature detection element detect the temperature of the air in the heat pipe in real time, and transmit the temperature signal to the control interface; make the pressure detection element detect the heat in real time The pressure in the tube, and transmit the pressure signa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap