Polarizer preparation method

A technology of polarizers and polarizers, applied in chemical instruments and methods, optics, polarizing elements, etc., can solve the problems of peeling, peeling, and random distribution of bright spots at the bonding interface, and achieve surface compatibility improvement and drying condition optimization , Reduce the effect of crack point defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Swell a polyvinyl alcohol resin film (PVA film) with a thickness of 75 μm in deionized water at 30° C. for 2 minutes, and dissolve it in an aqueous solution containing 0.08 wt % iodine (which contains KI, and the weight ratio iodine: KI=1:16) , soaked at 30°C for 1 minute to absorb dichroic substances, then washed with pure water for 15 seconds, then soaked in a mixed aqueous solution of 55°C containing 4wt% boric acid and 5wt% KI, and extended to the original Membrane 5.5 times, followed by washing with deionized water for 10 seconds at room temperature, into the plain membrane to dry.

[0058] The plain film drying is divided into four sections, low temperature section: temperature 40 ℃, humidity 80% RH, residence time 45 seconds; medium temperature section: temperature 48 ℃, humidity 80% RH, residence time 100 seconds; high temperature section: temperature 78 ℃, humidity 70 %RH, residence time 30 seconds; cooling section: temperature 40℃, humidity 60%RH, residence ti...

Embodiment 2

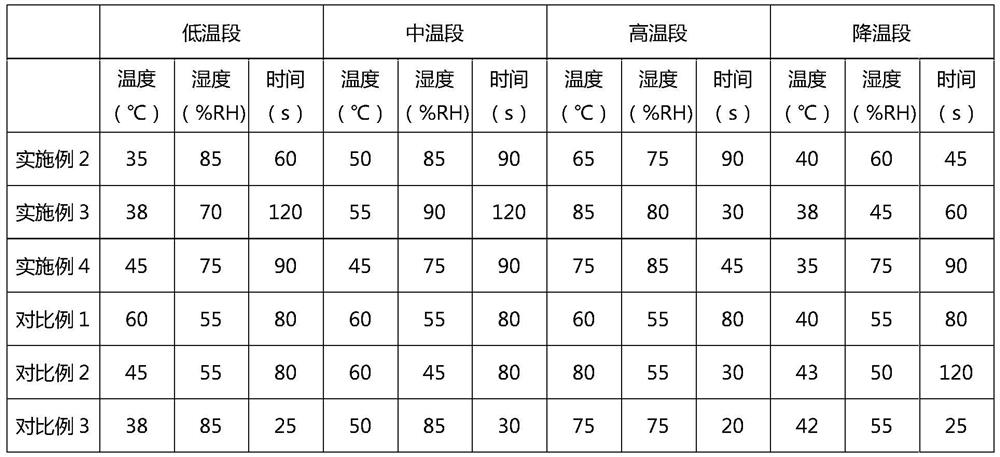

[0064] The specific drying process of Example 2-Experimental Example 4, Comparative Example 1-Comparative Example 3 is shown in Table 1, and the sample preparation and testing process are consistent with those of Example 1.

[0065] Table 1 embodiment and the plain film drying condition contrast table of comparative example

[0066]

[0067] Examples and comparative examples were detected according to the detection content and detection method as described in Example 1, and the results are shown in Table 2.

[0068] Table 2 Comparison table of crack point defect inspection results of embodiment and comparative example

[0069] A test B test Degree of polarization (%) Transmittance (%) Moisture content (%) Remark Example 1 1 2 99.97 42.3 2.88 Example 2 0 1 99.92 42.5 2.54 Example 3 1 2 99.93 42.4 2.21 Example 4 2 2 99.94 42.5 2.75 Comparative example 1 18 21 99.93 42.4 2.59 Comparative exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com