Petrochemical enterprise oily sludge deoiling treatment method

A petrochemical and oil treatment technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment by temperature control, etc. High problems, to achieve the effect of increasing spontaneous combustion, improving sludge drying conditions, and reducing sludge oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

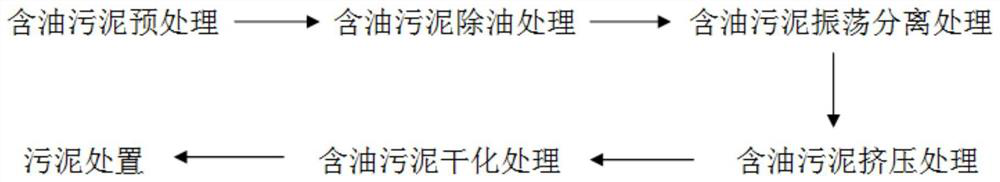

[0031] Oily sludge is hazardous waste, and activated sludge is general waste. The mixed treatment of oily sludge and activated sludge will affect the disposal method and cost of dried sludge. Therefore, oily sludge should be dried and disposed of separately. . Its treatment methods include:

[0032] The oily sludge in petrochemical enterprises is lifted by the system sludge lifting pump, and then sent to the oily sludge degreasing device for degreasing treatment, and the discharged sewage is used for oil recovery. The oily sludge after degreasing treatment enters the extrusion dehydrator for extrusion dehydration treatment alone, and the discharged sewage is treated together with the sewage discharged from the oily sludge degreasing device for waste oil recovery treatment. The oily sludge after extrusion dehydration is sent to the drying machine for drying treatment, and the sludge after drying treatment is disposed of separately. Its detailed production steps are:

[0033]...

Embodiment 2

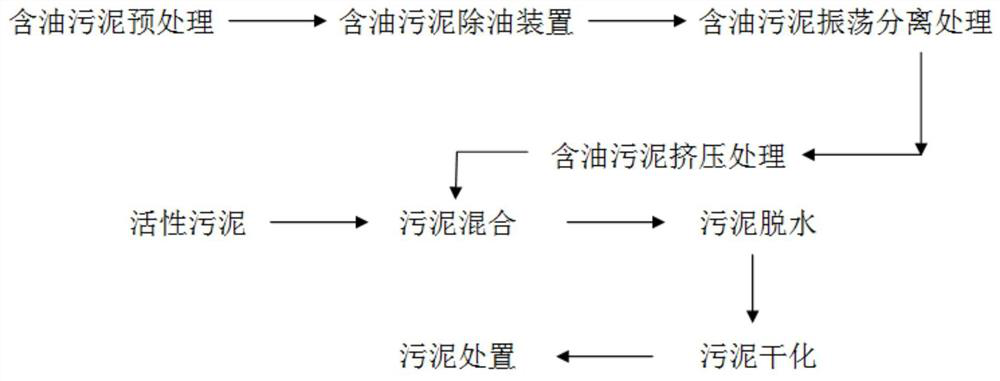

[0055] The oily sludge after degreasing and extrusion is mixed with activated sludge and sent to the enterprise incinerator or power station for incineration, which does not affect the disposal method and cost of dried sludge. Its treatment methods include:

[0056] The oily sludge in petrochemical enterprises is lifted by the system sludge lifting pump, and then sent to the oily sludge degreasing device for degreasing treatment, and the discharged sewage is used for oil recovery. The oily sludge after oil removal treatment enters the extrusion treatment for extrusion treatment alone, and the discharged sewage is treated together with the sewage discharged from the oily sludge degreasing device for waste oil recovery treatment. The oily sludge after extrusion treatment is sent to the oily sludge and activated sludge mixing facility for mixing conditioning treatment, and after being lifted, it is sent to the sludge dewatering machine for dehydration treatment. The mixed sludge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com