Processing method of chickpea defatted powder

A processing method, chickpea technology, applied in the field of grain and oil deep processing, can solve the problems of affecting the flavor and quality of protein products, loss of starch and cellulose, and affecting the shelf life of powder products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

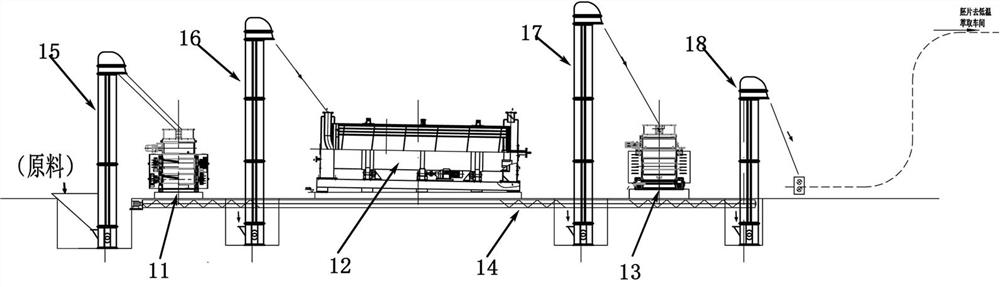

Method used

Image

Examples

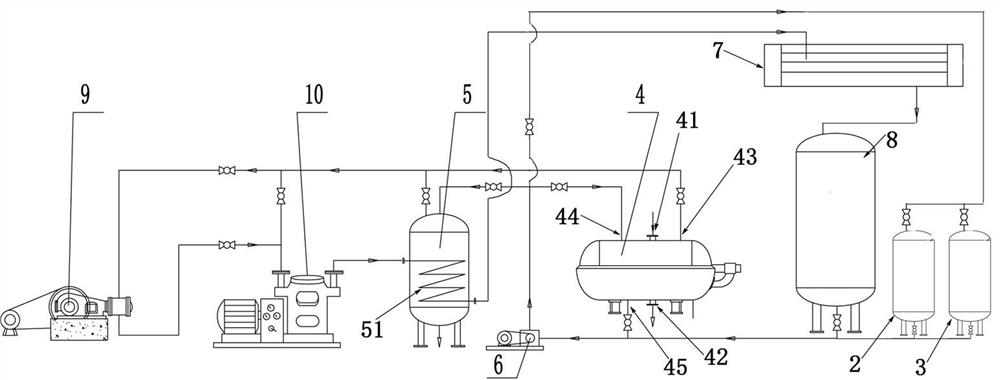

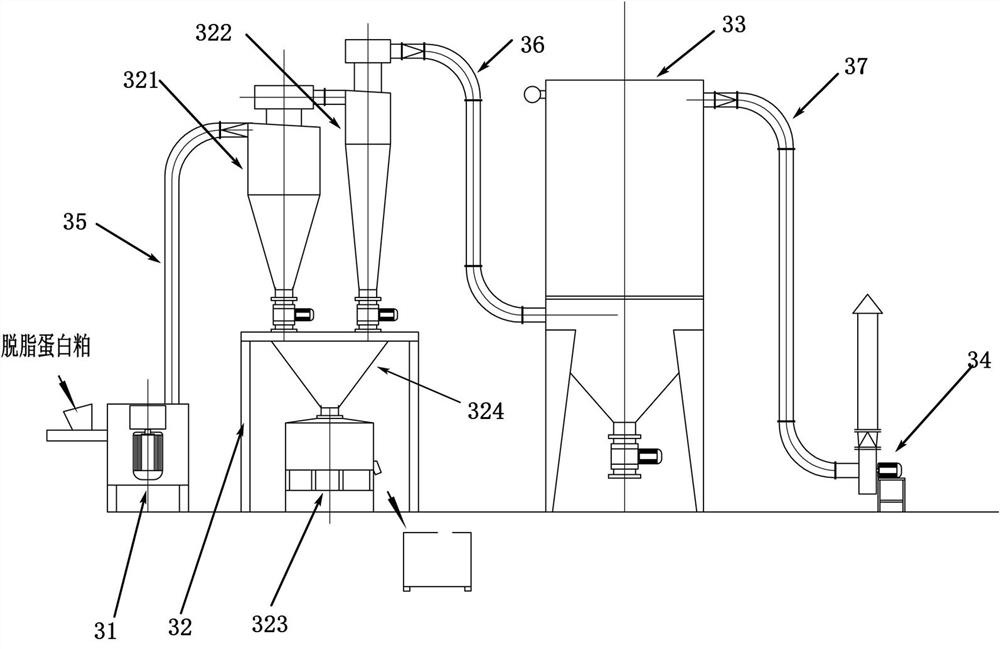

Embodiment 1

[0049] Break the peeled chickpeas into 4 petals, soften again, the softening temperature is 65°C, press the embryo again, the thickness of the embryo sheet is 0.26mm, and transport the embryo sheet to the extraction tank by air; when the material reaches 70% of the volume of the extraction tank When measuring, close the feed valve, turn on the vacuum pump, and discharge the air in the extraction tank. When the gauge pressure is -0.08MPa, close the vacuum pump and the corresponding valve, use liquefied butane as the extraction aid, and open the aid inlet valve and the aid Pump, inject the second extraction liquid from the last extraction tank as the first extraction aid for the material, material: liquid = 1:1; jacket heating, the temperature of the extraction tank is kept at 45 ° C, and the extraction pressure is maintained at 0.6 MPa , soak for 40min, open the drain valve, discharge the first extraction to the concentration tank; open the auxiliary agent inlet valve and auxili...

Embodiment 2

[0051] The chickpeas are cleaned of impurities, broken into 6 petals, and then softened. The softening temperature is 60°C, and the embryos are pressed again. The thickness of the embryos is 0.29mm, and the embryos are transported to the extraction tank by air; When measuring, close the feed valve, open the vacuum pump, and discharge the air in the extraction tank. When the gauge pressure is -0.085MPa, close the vacuum pump and the corresponding valve, use liquefied propane as the auxiliary agent, and open the auxiliary agent inlet valve and auxiliary agent pump. The second extraction solution injected into the previous extraction tank is used as the first extraction aid for the material, material: liquid = 1:0.8; the jacket is heated, the temperature of the extraction tank is maintained at 42 °C, and the extraction pressure is maintained at 1.6 MPa. 35min, open the drain valve, discharge the first extract to the concentration tank; open the auxiliary agent inlet valve and auxi...

Embodiment 3

[0053] Peeled chickpeas, broken into 6 petals, softened again, the softening temperature is 80°C, and then pressed embryos, the thickness of the embryos is 0.32mm, and the embryos are transported to the extraction tank by air; when the material reaches 75% of the volume of the extraction tank When measuring, close the feed valve, open the vacuum pump, and discharge the air in the extraction tank. When the gauge pressure is -0.09MPa, close the vacuum pump and the corresponding valve, use liquefied 134a as the auxiliary agent, and open the auxiliary agent inlet valve and auxiliary agent pump. The second extraction solution injected into the previous extraction tank is used as the first extraction aid for the material, material: liquid = 1:2; the jacket is heated, the temperature of the extraction tank is maintained at 45 ° C, the extraction pressure is maintained at 1.2 MPa, soak After 30 minutes, open the drain valve and discharge the first extract to the concentration tank; ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com