End-fixed assembly type spiral conveying shaft and method

A screw conveying shaft and screw shaft technology are applied in the field of end-fixed and assembled screw conveying shafts, which can solve the problems of affecting production efficiency, wear of screw blades, and high maintenance costs, and achieve the effects of improving efficiency, reasonable connection and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

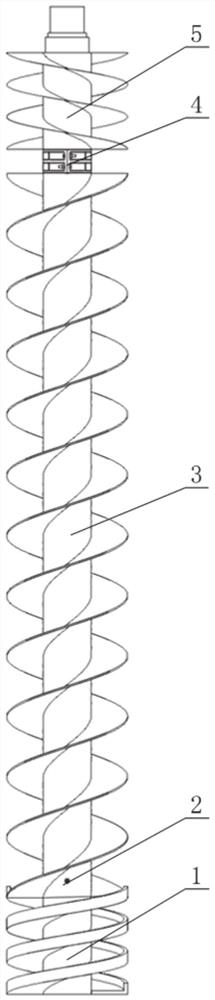

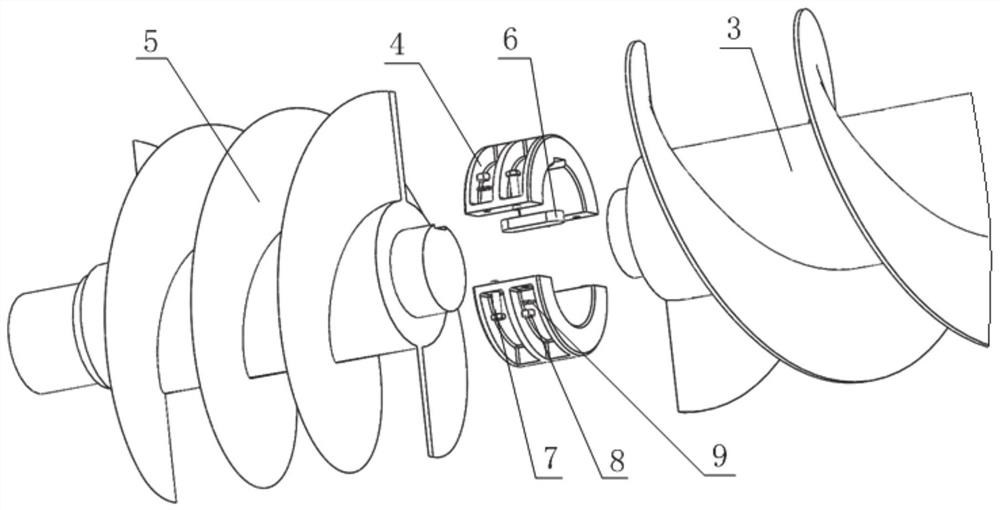

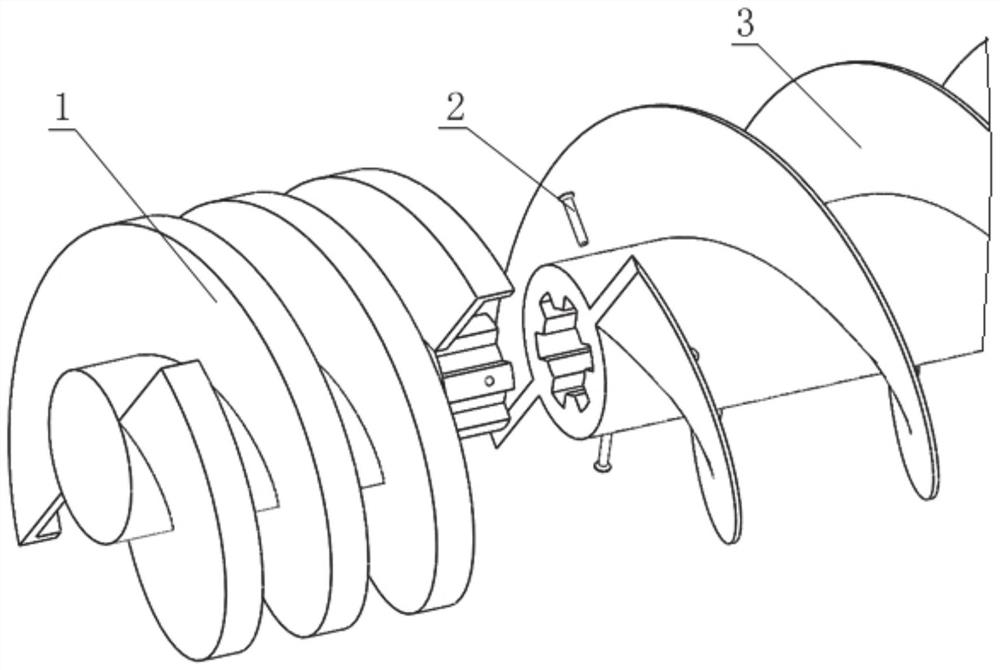

[0040] In a typical embodiment of the present invention, refer to figure 1As shown, an end-fixed assembled screw conveyor shaft includes at least three screw shafts that are detachably connected, and multiple screw shafts are connected in sequence to form a conveyor shaft. Each screw shaft is provided with a screw blade, and the screw shaft at the feed end 1. It is connected with the screw blade of the screw shaft connected to it. There is a gap between the screw shaft 5 at the discharge end and the screw blade of the screw shaft connected to it. In theory, the bulk material will flow out of this gap, but in actual production it will Due to the large conveying volume, the residual bulk material cannot be discharged in time, and some material will enter the screw blade at the discharge end, so that even if some material flows through the screw shaft at the discharge end, not all the material will pass through the discharge end. end screw shaft, so that the overall loss of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com