Universal ethylene cracking furnace coil pipe hanging test tool and test method

An ethylene cracking furnace, a general-purpose technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems affecting the service life of the ethylene cracking furnace coil, the deviation of the center distance of the pipe fittings, and the coil bearing. The effect of reducing costs, extending service life, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further explained below.

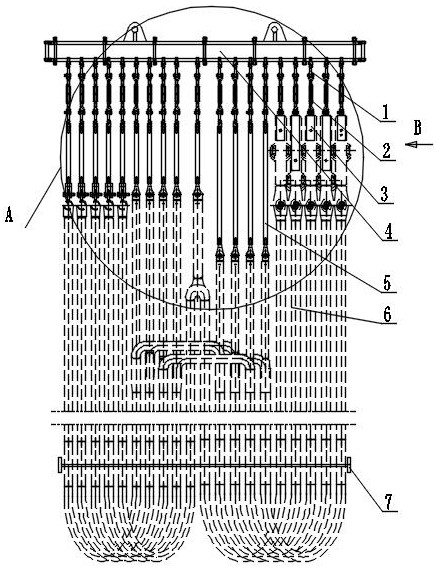

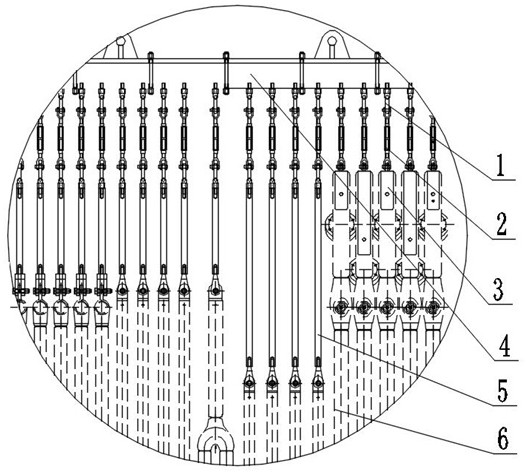

[0031]With reference to the attached drawings, the universal ethylene cracking furnace coil tube hanging test tool includes a main hanging beam 4 and a universal hoisting ring 1, characterized in that: the lower part of the main hoisting beam 4 is connected with several universal hoisting rings 1, universal hoisting rings 1 UU-shaped turnbuckle screw 2 is connected to the lower part; the top of one end of the coil 6 is connected with the UU-shaped turnbuckle screw 2 through the bu-shaped tube lifting rod assembly 3, and the other end of the coil 6 is connected with the UU-shaped turnbuckle screw 2 through the middle connector 5; The lower part of the coil 6 is provided with auxiliary tooling 7.

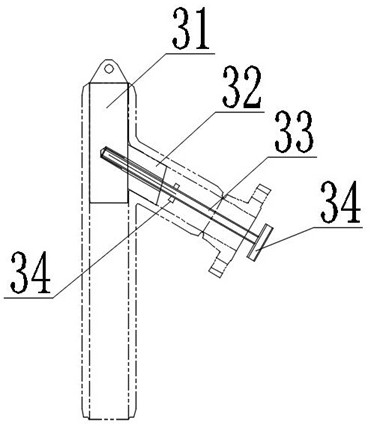

[0032]In this preferred embodiment, the bu-shaped tube lifting tool 3 includes a main boom 31, the main boom 31 is provided with a support boom 32 obliquely on its side, a handle 35 is provided at one end of the locking rod 34, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com