Stable assembly type glass partition with lateral supporting structure

A lateral support and stable technology, applied in the direction of building components, building structure, earthquake resistance, etc., can solve the problems of insufficient support mechanism strength, low energy absorption and shock absorption effect, lack of assembly portability, etc., to improve the support effect, Effect of improving stability and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

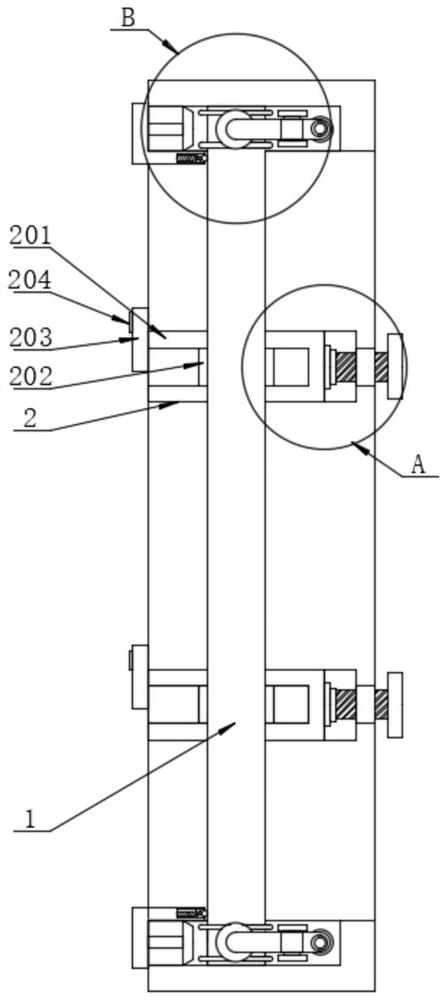

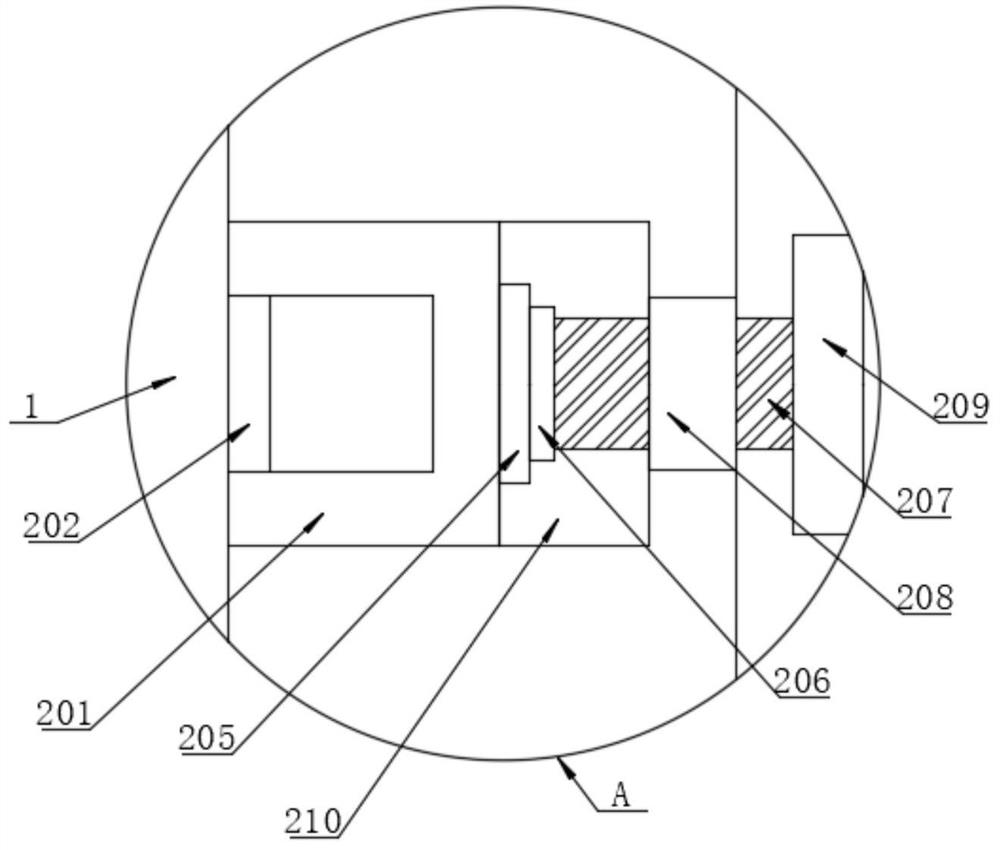

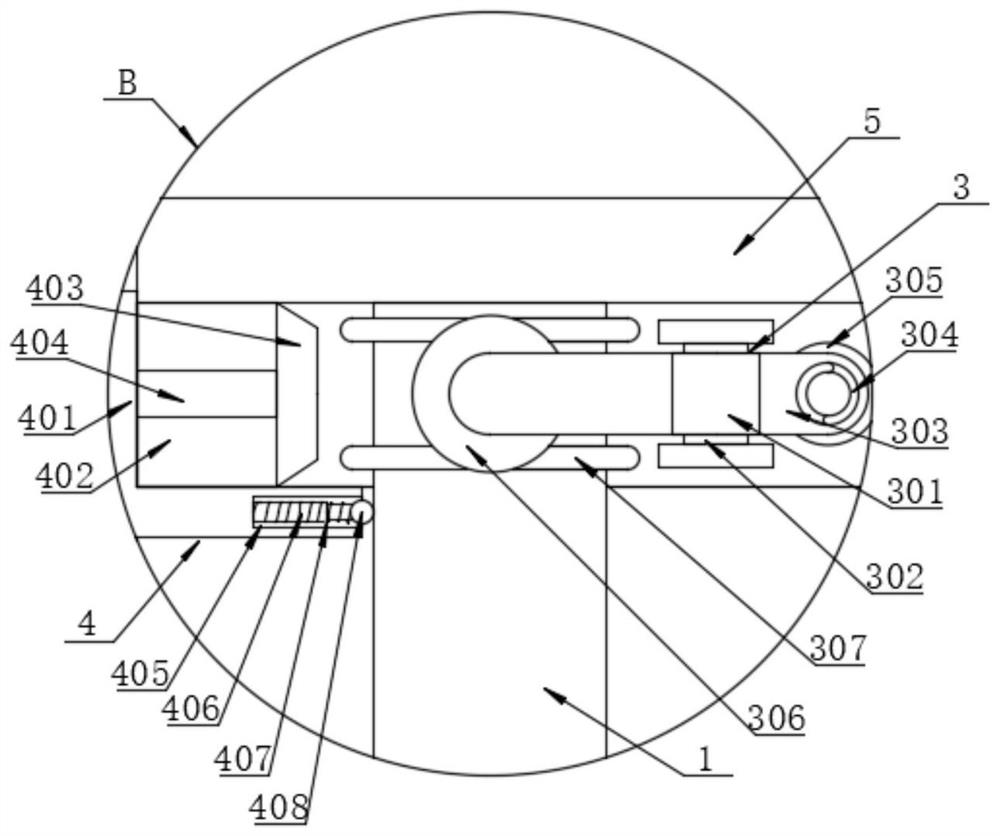

[0043] The embodiment is specifically: when the glass panel 1 is assembled, the glass panel 1 can slide into the slide seat 201 through the slider 202, the T-shaped slide block 202 can avoid moving out from the slide seat 201, and the slide block 202 can prevent the glass panel from moving out of the slide seat 201. 1 Deviation occurs after assembly, and when the slider 202 and the sliding seat 201 are completely slid into the chute 210, they can rotate around the pin shaft 204 by pulling the baffle 203, and the baffle 203 can be rotated to fit with the sliding seat 201 on one side , prevent the slider 202 from moving out of the chute 210 due to external shaking, and improve the stability of the placement of the glass panel 1. At the same time, after the slide seat 201 is assembled, the threaded column 207 can be driven to rotate in the threaded cap 208 by turning the handle 209, and the threaded column 207 is threaded. The threaded cap 208 of the threaded cap 208 rotates and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com