Centrifugal impeller and ventilator thereof

A centrifugal impeller and impeller technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as limited use occasions, increased impeller volume, and increased cost, and achieve small shrinkage and rebound, increase roundness degree, ensure the effect of beating and dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment specifically illustrates the effect of adding a straight inlet section at the inlet of the front plate.

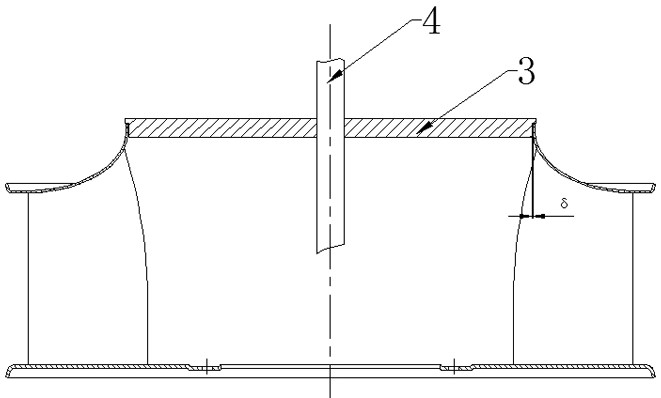

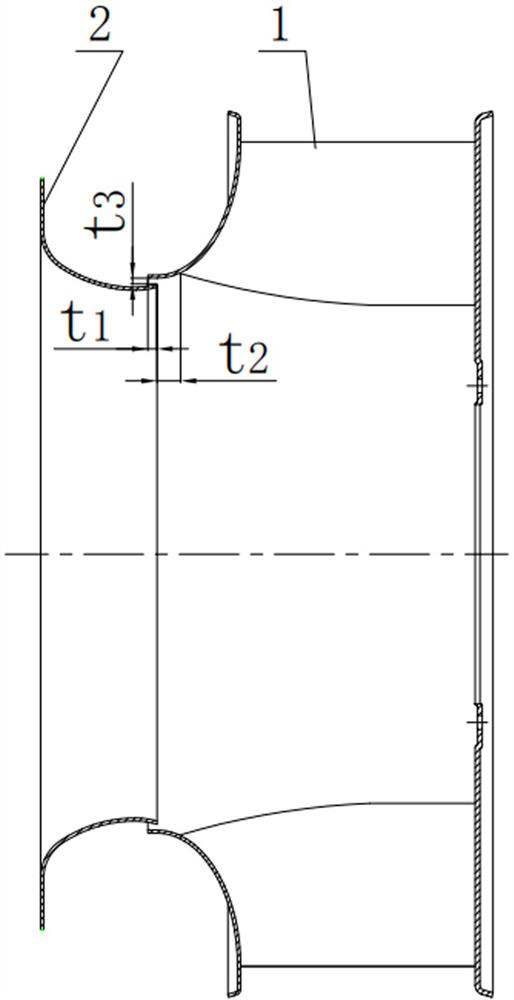

[0035] Such as figure 1 As shown, when the rear disk 11, blades 12, and front disk 13 of the centrifugal impeller are assembled and welded, the center of the front disk is positioned by the vertical mandrel 4 and the large disc 3, wherein the mandrel is the axial centerline of the impeller 1 , the gap between the large disk and the inner wall of the entrance of the front disk is δ, and the horizontal direction and the vertical direction of the front disk are all positioned. In the front disc of the prior art, the inner circle of the front disc has a certain degree of ellipticity due to uneven shrinkage and deformation during mold pressing. In order to ensure that the minimum inner diameter of the front disc can trap the large disc, the outer diameter of the large disc must be turned Small size, resulting in uneven distribution of mass in the circumf...

Embodiment 2

[0040] This embodiment specifically illustrates the function of the arc section of the main body.

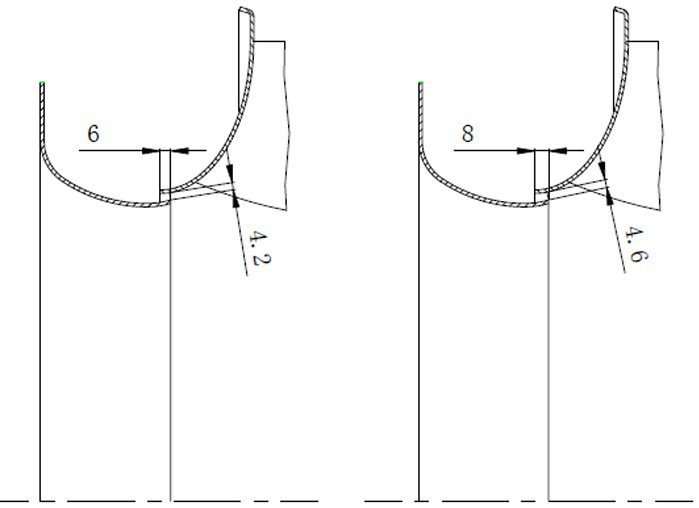

[0041] Comparing Example 2 of the present invention with Comparative Prototype 1, except for the difference in the section arc of the arc section of the main body, the remaining parts of the ventilator are completely the same, and the matching motor and operating speed are also the same. The cross-sectional shape of the main body arc section of comparative prototype 1 is a circular arc, and the cross-sectional shape of the main body arc section of Example 2 is the curve of the main body arc section of the present invention, including a straight inlet section "ab", a main body arc section "bc", and a flat Straight exit section "cd" and exit flange section "def".

[0042] Embodiment 2 and comparative prototype 1 relevant dimensions are as follows:

[0043] D. 2 =526.6 mm

[0044] D. 0 =352.5 mm

[0045] D. 3 =566 mm

[0046] s=6mm

[0047] u=87 mm

[0048] v=53.5 mm

[0...

Embodiment 3

[0056] This embodiment specifically illustrates the function of the arc section of the main body through another impeller size.

[0057] Comparing Example 3 of the present invention with Comparative Prototype 2, except for the difference in the section arc of the arc section of the main body, the remaining parts of the ventilator are identical, and the matching motor and operating speed are also the same. The cross-sectional shape of the arc section of the main body of the comparative prototype 2 is a circular arc, and the arc section of the main body in Example 3 is the curve of the arc section of the main body of the present invention.

[0058] Embodiment 3 and comparative prototype 2 relevant dimensions are as follows:

[0059] D. 2 =639.6mm

[0060] D. 0 =444mm

[0061] D. 3 =716mm

[0062] s=7mm

[0063] u=97.8mm

[0064] v=68mm

[0065] θ=34.8°

[0066] v / u=0.695

[0067] The performance curve comparison of embodiment 3 and comparative prototype 2 sees Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com