Preparation method of Alk-Ti3C2/PDMS flexible piezoresistive sensor

A piezoresistive sensor, flexible technology, applied in the field of preparation of Alk-Ti3C2/PDMS flexible piezoresistive sensor materials, can solve the problem that piezoresistive sensors cannot take into account high sensitivity and wide pressure range at the same time, limit the scope of sensor use, single two Dimensional planar structure and other issues, to achieve the effect of simple and feasible preparation method, strong plasticity, and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

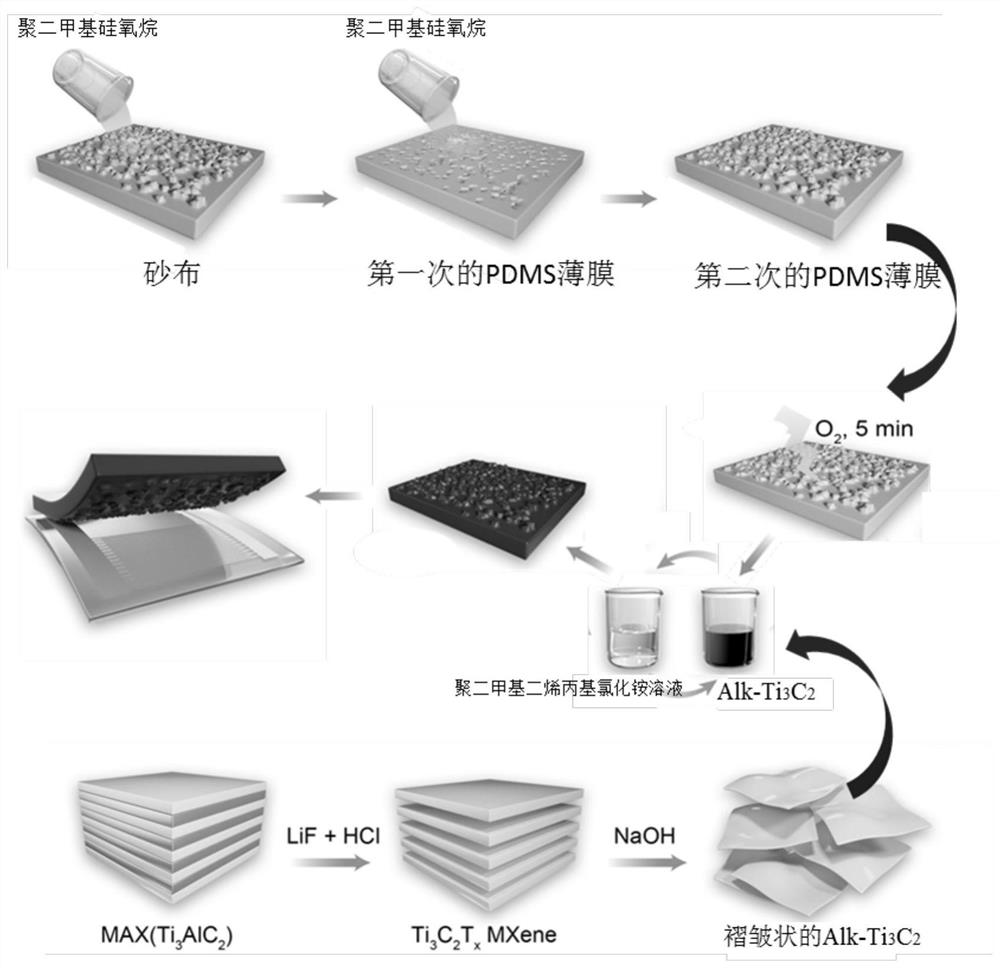

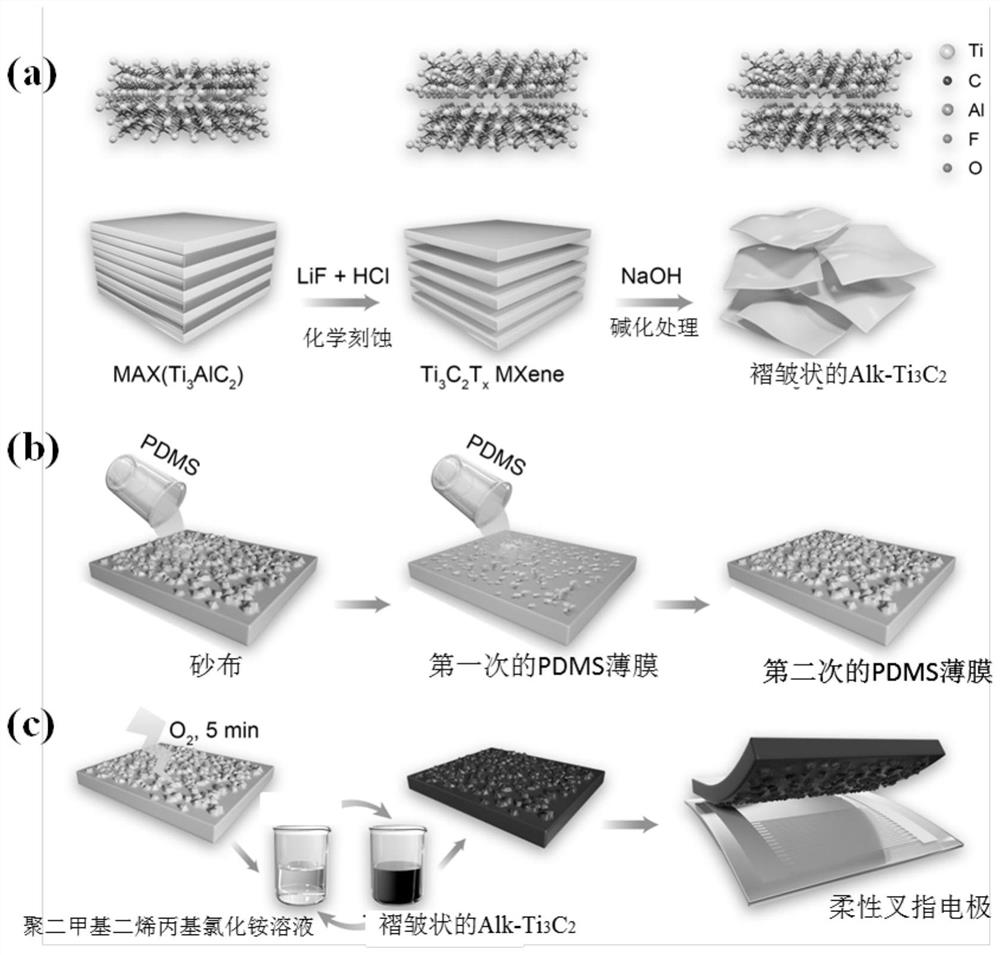

[0058] Alk-Ti 3 C 2 The preparation method of / PDMS flexible piezoresistive sensor adopts following steps to obtain:

[0059] Step 1, prepare structured PDMS flexible film substrate:

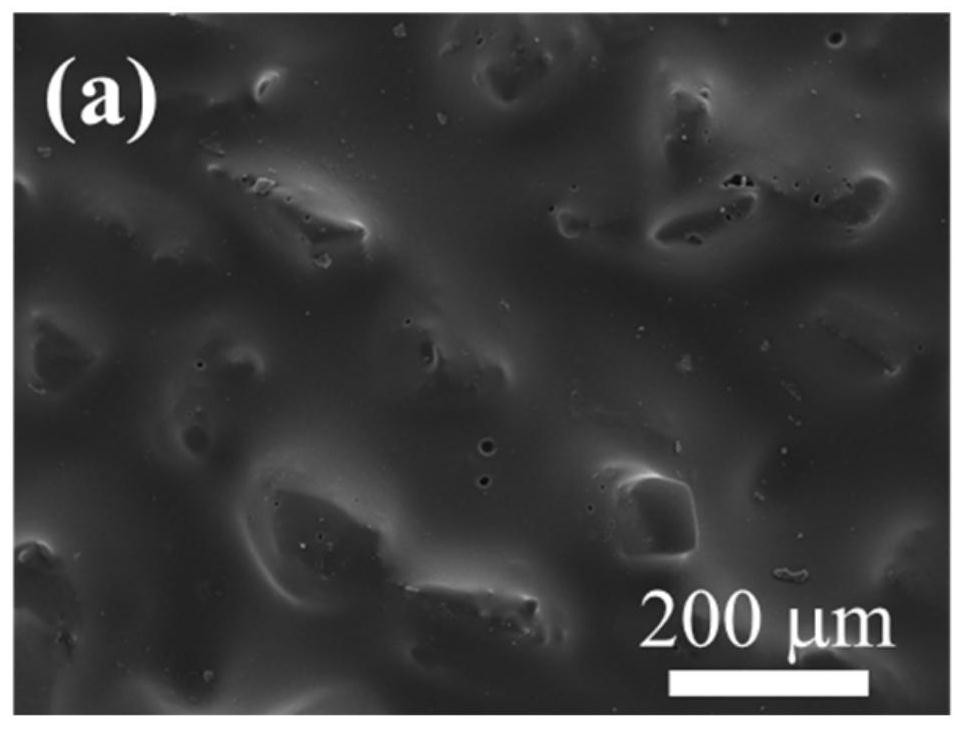

[0060] The PDMS film substrate was simply prepared by a two-step method using abrasive cloth as a template. In this example, use deionized water and alcohol to clean and dry the emery cloth with raised structures on the surface, mix the silica gel base liquid and curing agent according to the ratio of 10:1, stir it for ten minutes, pour it on the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com