State maintenance method, system and terminal for steam turbine generators

A steam turbine generator and condition maintenance technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of power plant operation safety impact, excessive equipment maintenance, waste of manpower and material resources, etc. Operation ability and equipment management level, and the effect of condition-based maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

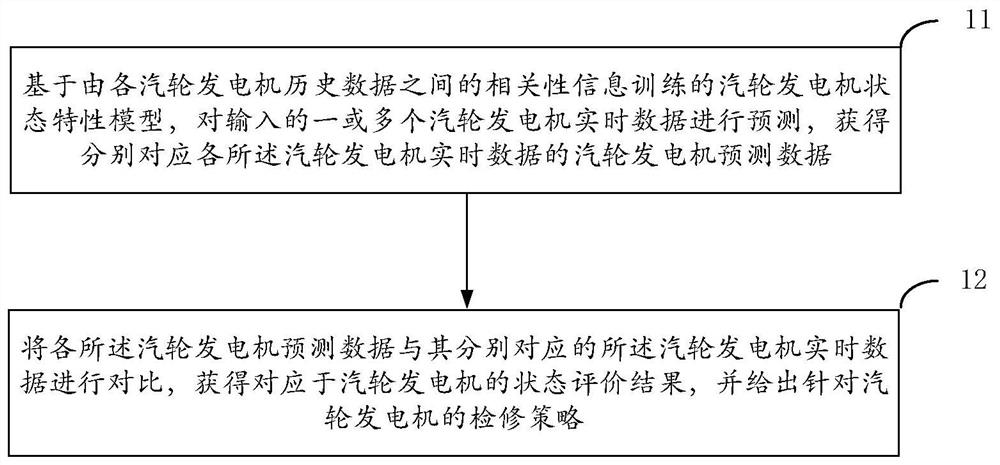

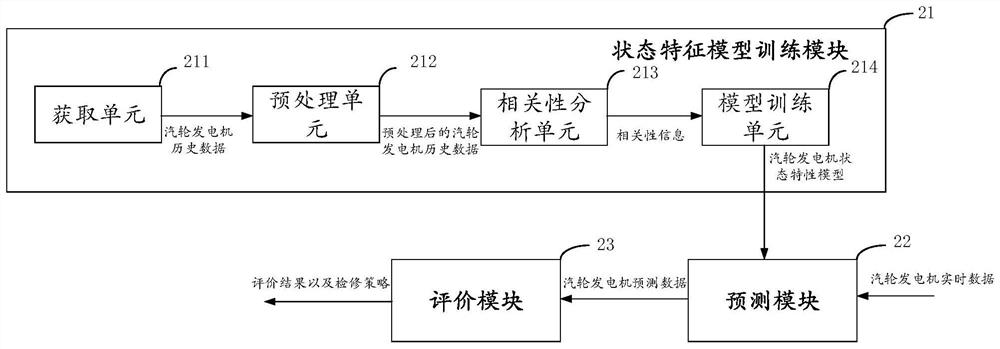

[0054] Such as figure 2 A schematic structural diagram of a system showing a condition-based maintenance method for a turbogenerator in an embodiment of the present invention.

[0055] The system includes:

[0056] The state characteristics model training module 21 includes: an acquisition unit 211, a preprocessing unit 212, a correlation analysis unit 213 and a model training unit 214; wherein,

[0057] The acquiring unit 211 is used to acquire the historical data of each turbogenerator; the preprocessing unit 212 is connected to the acquiring unit 211 for preprocessing the historical data of each turbogenerator; the correlation analysis The unit 213 is connected to the preprocessing unit 212, and is used to perform correlation analysis on the preprocessed historical data of the turbo-generators to obtain correlation information between the historical data of the turbo-generators; the model training unit 214 Connecting the correlation analysis unit 213 for training and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com