Printing production line quality tracking management system and using method thereof

A management system and production line technology, applied in the field of printing production, can solve problems such as inability to classify and analyze, cost loss, and occurrence of unqualified products, and achieve the effect of facilitating later traceability, reducing cost loss, and ensuring no errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

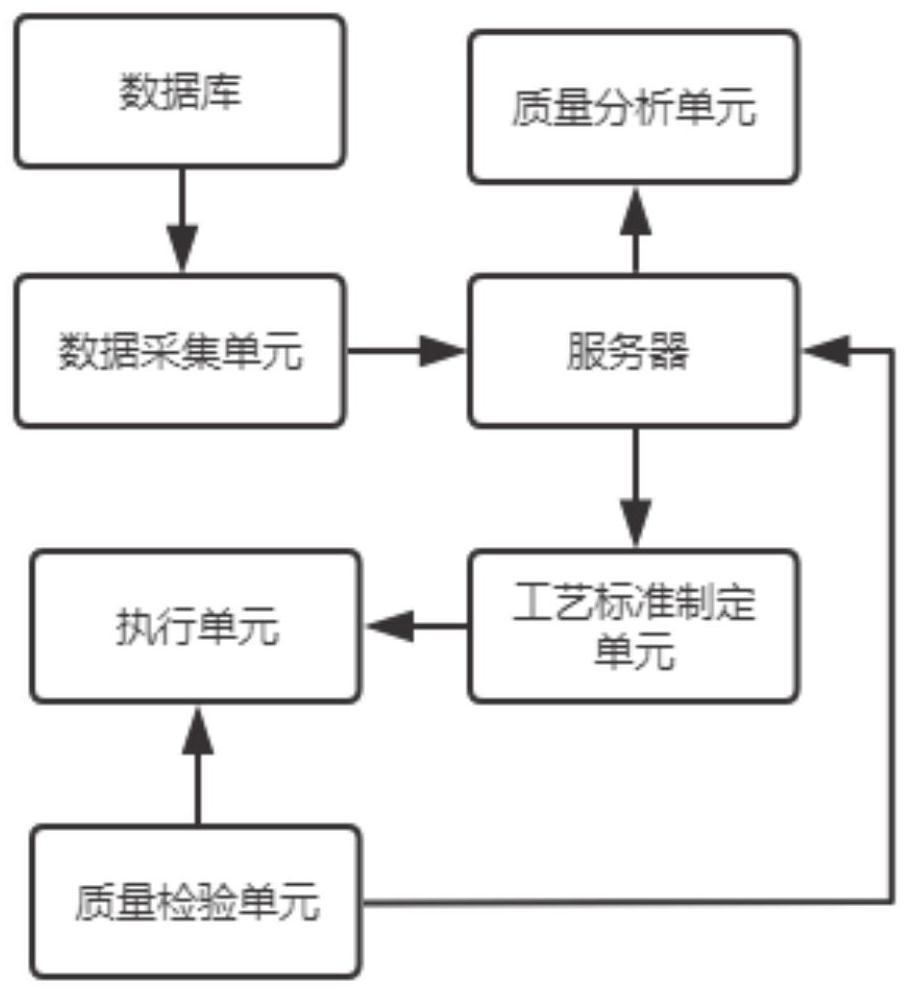

[0033] A printing production line quality tracking management system, such as figure 1 As shown, it includes a server, a database, a data acquisition unit, a process standard formulation unit, an execution unit, a quality inspection unit and a quality analysis unit, and the signal output terminal of the server is connected to the process standard formulation unit; the signal output terminal of the database Communicatively connected with the data acquisition unit; the signal output end of the data acquisition unit is communicatively connected with the server; the signal output end of the process standard formulation unit is communicatively connected with the execution unit; the execution unit is at least one combination of printing equipment and a paper roll , the paper roll is provided with an electronic label, and the electronic label is the paper roll quality information carrier, which is convenient for quickly searching for products; the signal output end of the quality insp...

Embodiment 2

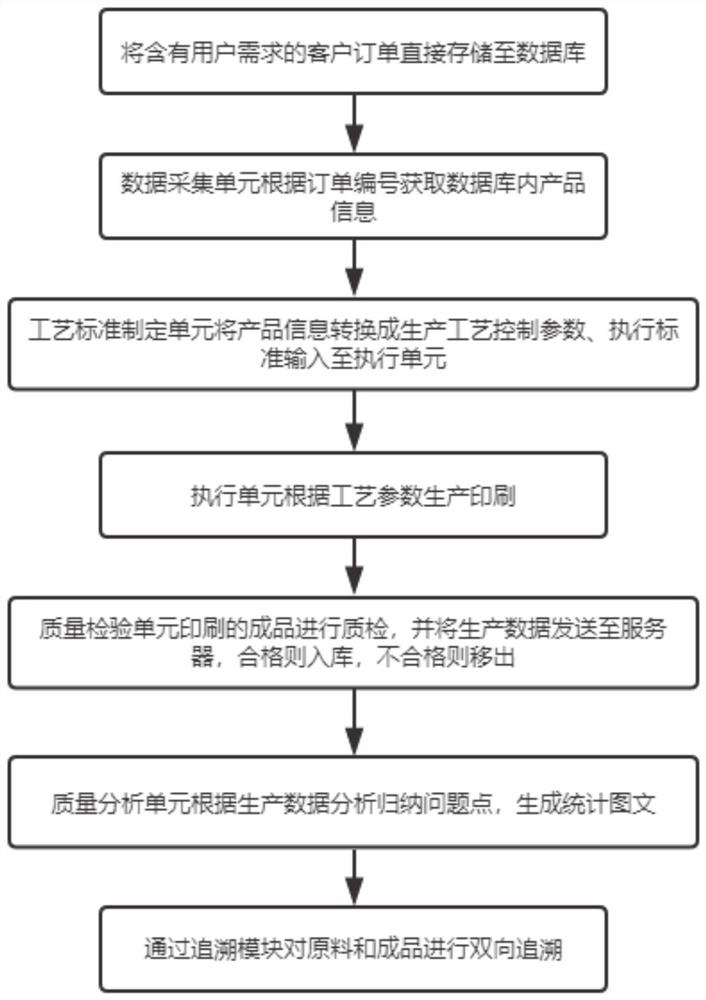

[0045] A method for using the printing production line quality tracking management system described in Embodiment 1, such as figure 2 shown, including the following steps:

[0046] S1: Store customer orders containing user needs directly into the database;

[0047] S2: The data collection unit obtains the product information in the database according to the order number;

[0048] S3: The process standard formulation unit converts product information into production process control parameters, and inputs the execution standard to the execution unit;

[0049] S4: The execution unit produces and prints according to the process parameters;

[0050] S5: The finished products printed by the quality inspection unit undergo quality inspection, and send the production data to the server.

[0051] S6: The quality analysis unit analyzes and summarizes the problem points according to the production data, and generates statistical graphics;

[0052] S7: Two-way traceability of raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com